OperatiOn

HPR800XD Auto Gas – 806500 4-31

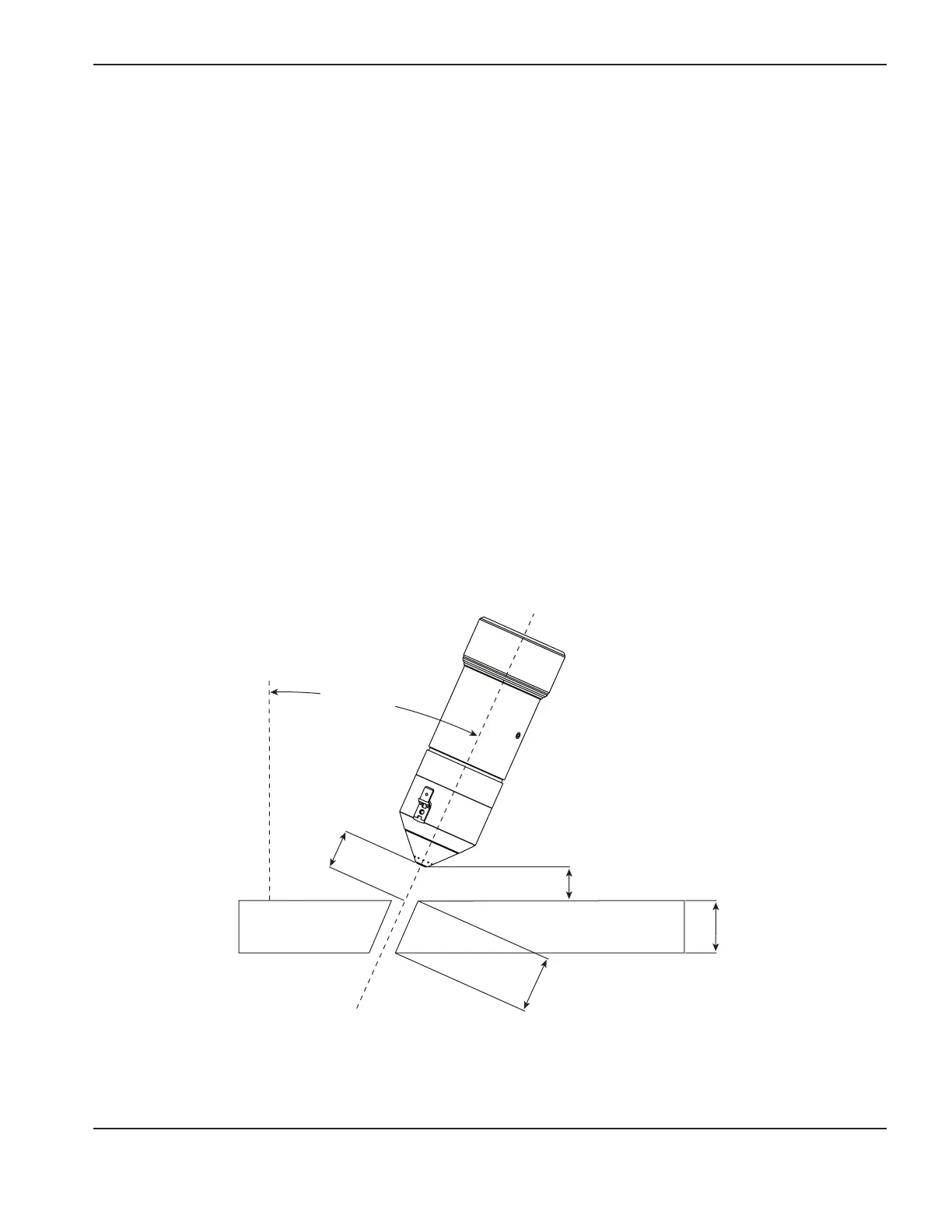

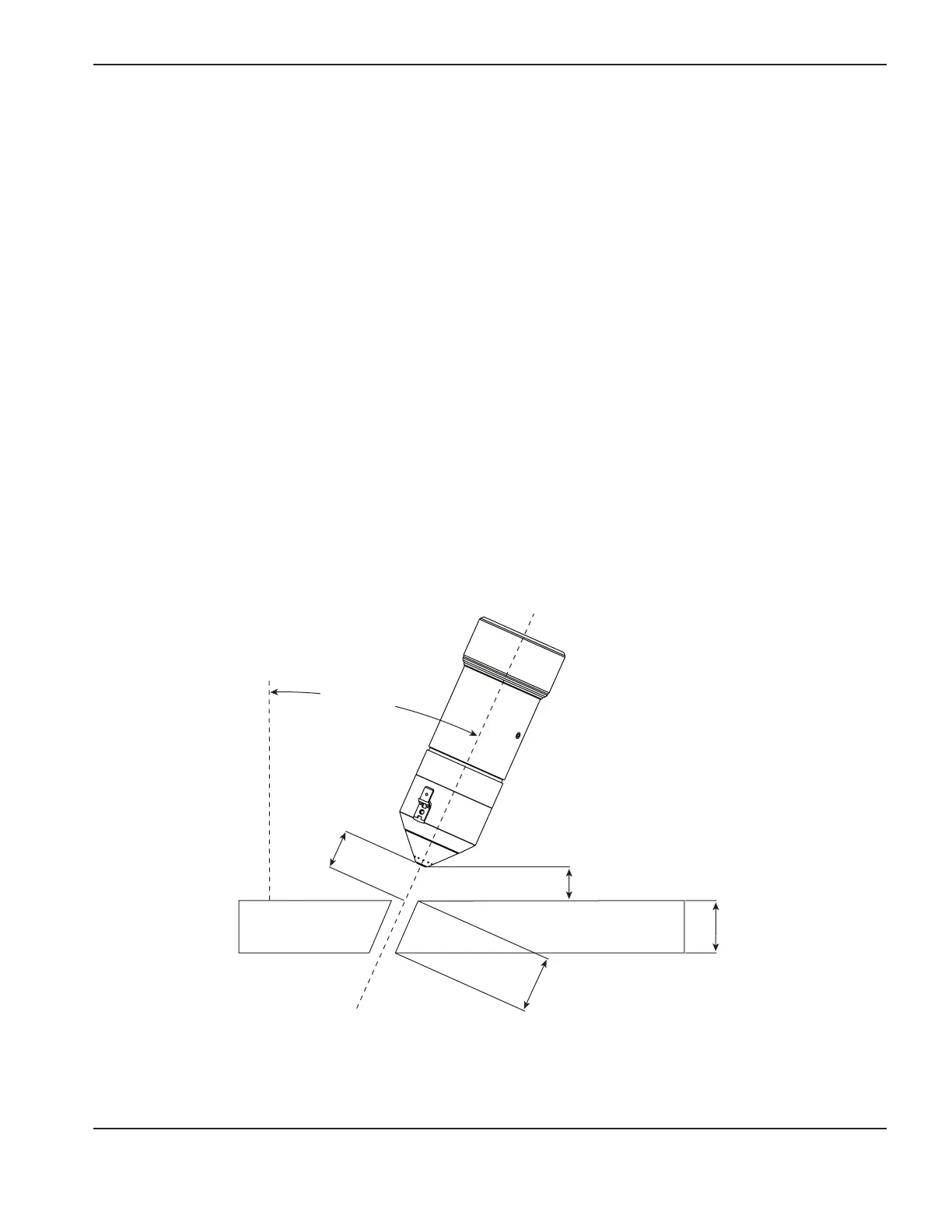

Bevel cutting definitions

Bevel angle The angle between the center line of the torch and a line that is perpendicular to the

workpiece. If the torch is perpendicular to the workpiece, the bevel angle is zero. The

maximum bevel angle is 45°.

Nominal thickness The vertical thickness of the workpiece.

Equivalent thickness The length of the cut edge, or the distance the arc travels through the material while cutting.

Equivalent thickness is equal to the nominal thickness divided by the cosine of the bevel

angle. Equivalent thicknesses are listed in the cut chart.

Clearance The vertical distance from the lowest point of the torch to the surface of the workpiece.

Torch-to-work distance The linear distance from the center of the torch outlet to the workpiece surface along the

torch center-line. A range of torch-to-work distances are listed in the cut chart. The smallest

number is for a straight cut (bevel angle = 0°). The largest number is for a 45° bevel cut

with a clearance of 3 mm (0.120 in).

Arc voltage The arc voltage setting is dependent on the bevel angle and the setup of the cutting system.

The arc voltage setting on one system may be different from a second system even if the

workpiece is the same thickness. The arc voltages for bevel cutting are not supplied in the

bevel cut charts.

Bevel angle

Torch-to-work

distance

Torch

center-line

Clearance

Nominal

thickness

Equivalent

thickness

0°

Loading...

Loading...