MAX200 Instruction Manual 3-5

1-97

SETUP

WARNING

Propylene glycol and benzotriazole are irritating to skin and eyes, and harmful or fatal if

swallowed. Upon contact, flush skin or eyes with water. If swallowed, drink water and call a

physician immediately. Do not induce vomiting.

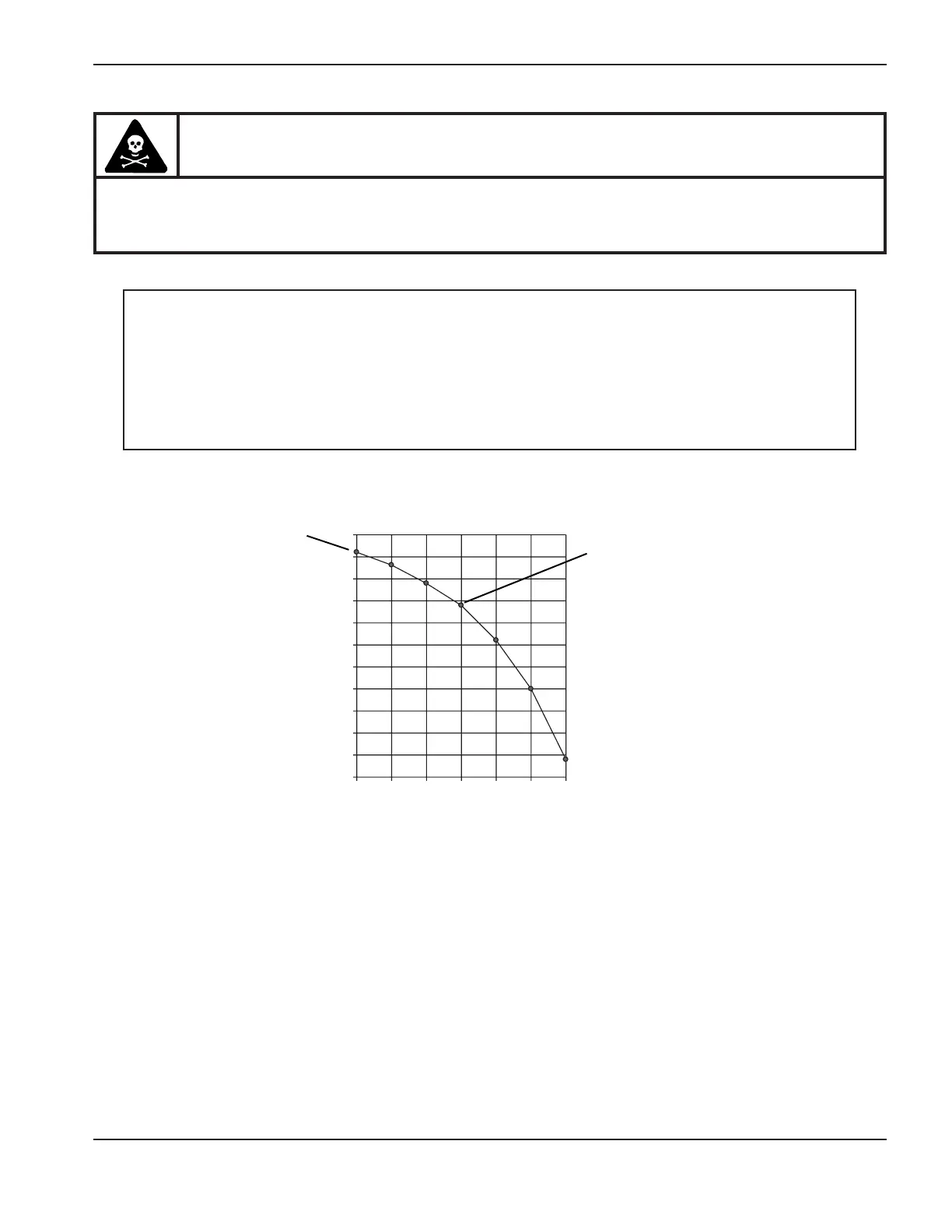

Caution: Always use propylene glycol in the coolant mixture. Do not use anti-freeze in place

of propylene glycol. Anti-freeze contains corrosion inhibitors that will damage the

torch coolant system.

Always use purified water in the coolant mixture in order to prevent corrosion in the

torch coolant system. The hardness of purified water should be between .206 and

8.5 ppm. If using a conductivity meter to measure water purity, the recommended

level is between .5 and 18 µSiemens/cm at 77° F (25° C).

32 °F (0 °C)

10 °F (-12 °C)

(mixture resists

freezing to this

temperature)

Propylene Glycol (%)

Temperature ° F

Filling the System

To fill the torch coolant tank prior to initial start-up:

1. Ensure the torch lead is connected. Refer to page 3-14, Connecting the Torch Lead Assembly.

Note: Always add coolant with the MAX200 system off.

2. Fill the tank with coolant until the level reaches the bottom of the neck, approximately 2.9 gallons (11 liters).

Loading...

Loading...