4-12 MAX200 Instruction Manual

OPERATION

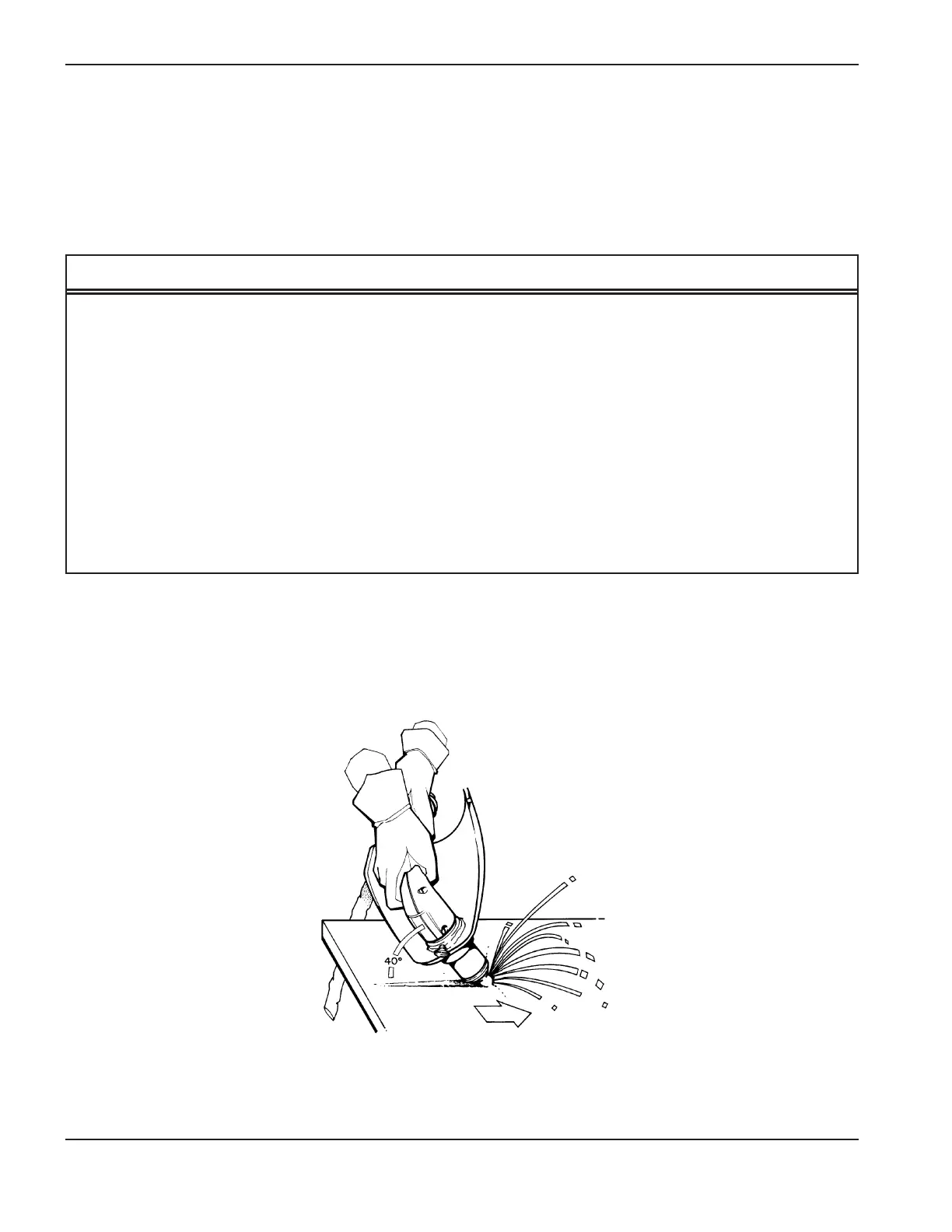

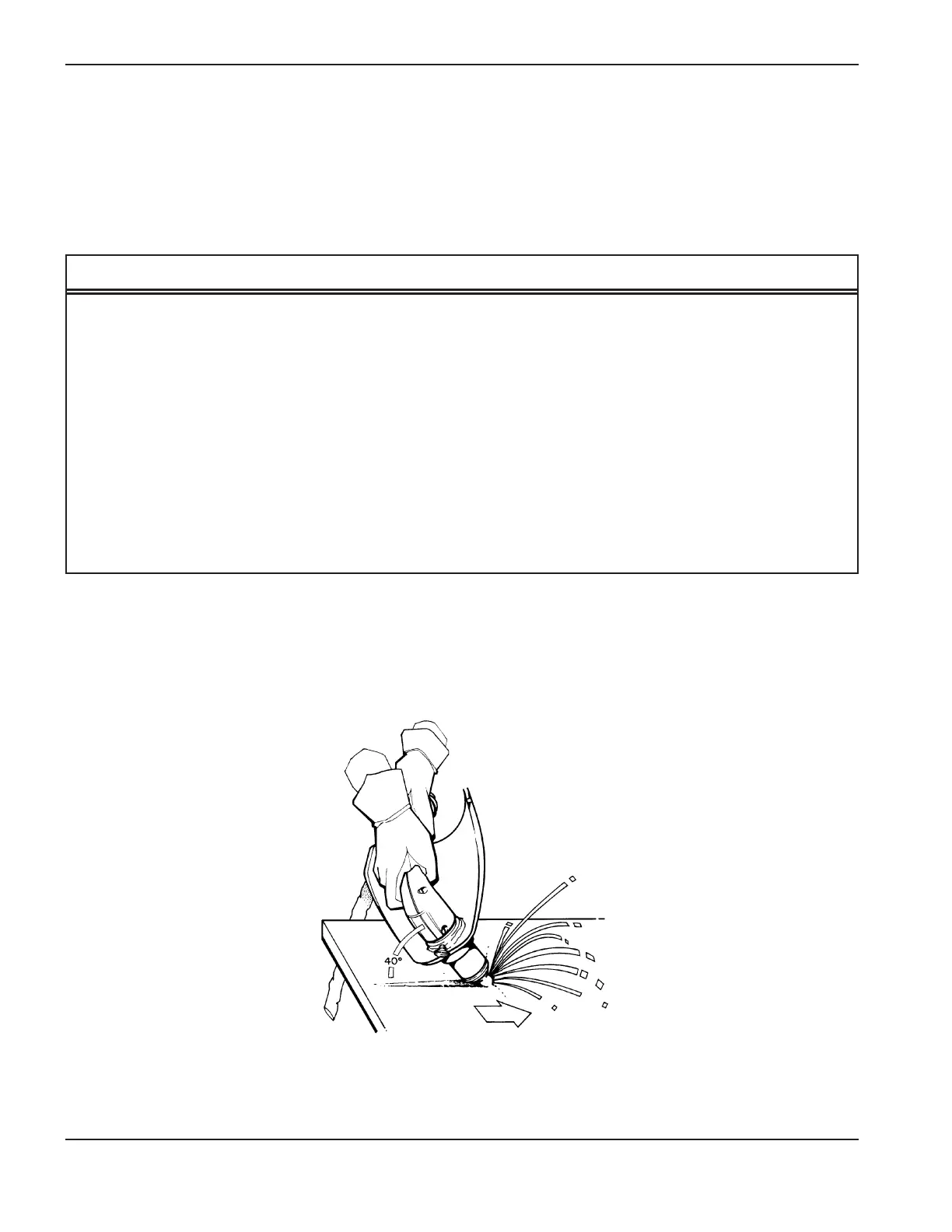

4. Tilt the torch approximately 40° from the surface to be gouged and feed into the gouge (Fig. 4-7). Use the

straight gouge (90°) or side gouge (45°) technique (see Figs. 4-8 and 4-9). Multiple passes or “weaving” may be

necessary to gouge wider and deeper sections (see Fig. 4-8 for straight weaving and Fig. 4-9 for side weaving).

5. When gouging mild steel, stainless steel, or aluminum, the approximate metal removal rates are as follows:

Metal Gouging Technique Metal Removal Rate*

Mild Steel Straight Gouge 46 lbs/hr (21 kg/hr)

Straight Weaving Gouge 66 lbs/hr (30 kg/hr)

Side Gouge 43 lbs/hr (19 kg/hr)

Side Weaving Gouge 65 lbs/hr (29 kg/hr)

Stainless Steel Straight Gouge 83 lbs/hr (37 kg/hr)

Straight Weaving Gouge 86 lbs/hr (39 kg/hr)

Side Gouge 77 lbs/hr (35 kg/hr)

Side Weaving Gouge 89 lbs/hr (40 kg/hr)

Aluminum Straight Gouge 36 lbs/hr (16 kg/hr)

Straight Weaving Gouge 41 lbs/hr (18 kg/hr)

Side Gouge 43 lbs/hr (19 kg/hr)

Side Weaving Gouge 52 lbs/hr (23 kg/hr)

* When Argon-Hydrogen is used as the plasma gas

Figure 4-7 Feeding Into Gouge

Loading...

Loading...