4-20 MAX200 Instruction Manual

9-99

OPERATION

PAC200T/PAC200E Hand Torch

Mild Steel

100 amps

•

Air Plasma / Air Shield

This gas combination gives good cut speed, low dross level and is very economical. Some surface

nitriding can occur. While this process may be used on thicker materials, optimal recommended range is to

3/8 inch (10 mm).

Piercing above 5/8 inch (15 mm) not recommended.

* If leads are greater than 50 feet, increase TEST pressure 5 psi for every extra 50 feet of torch lead length.

020919

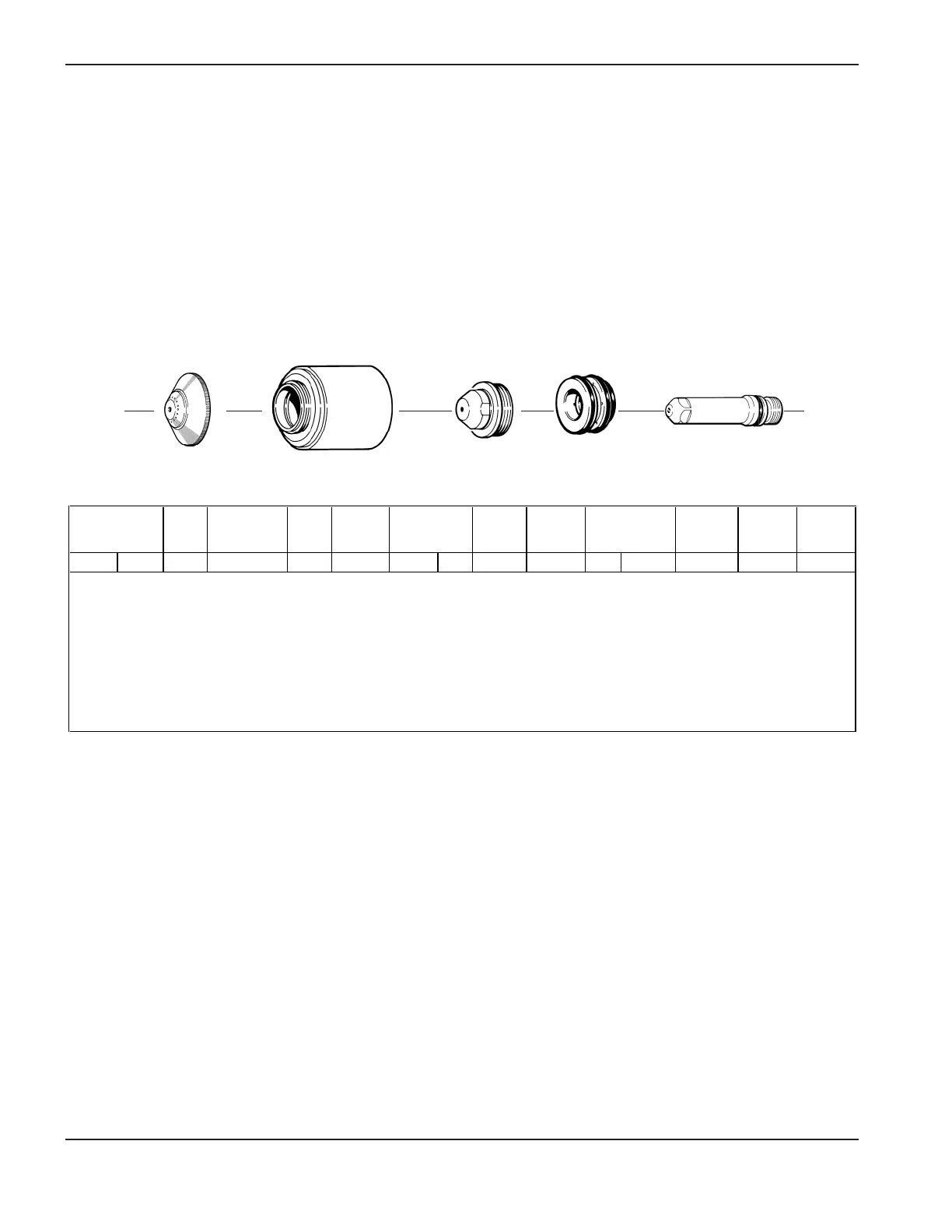

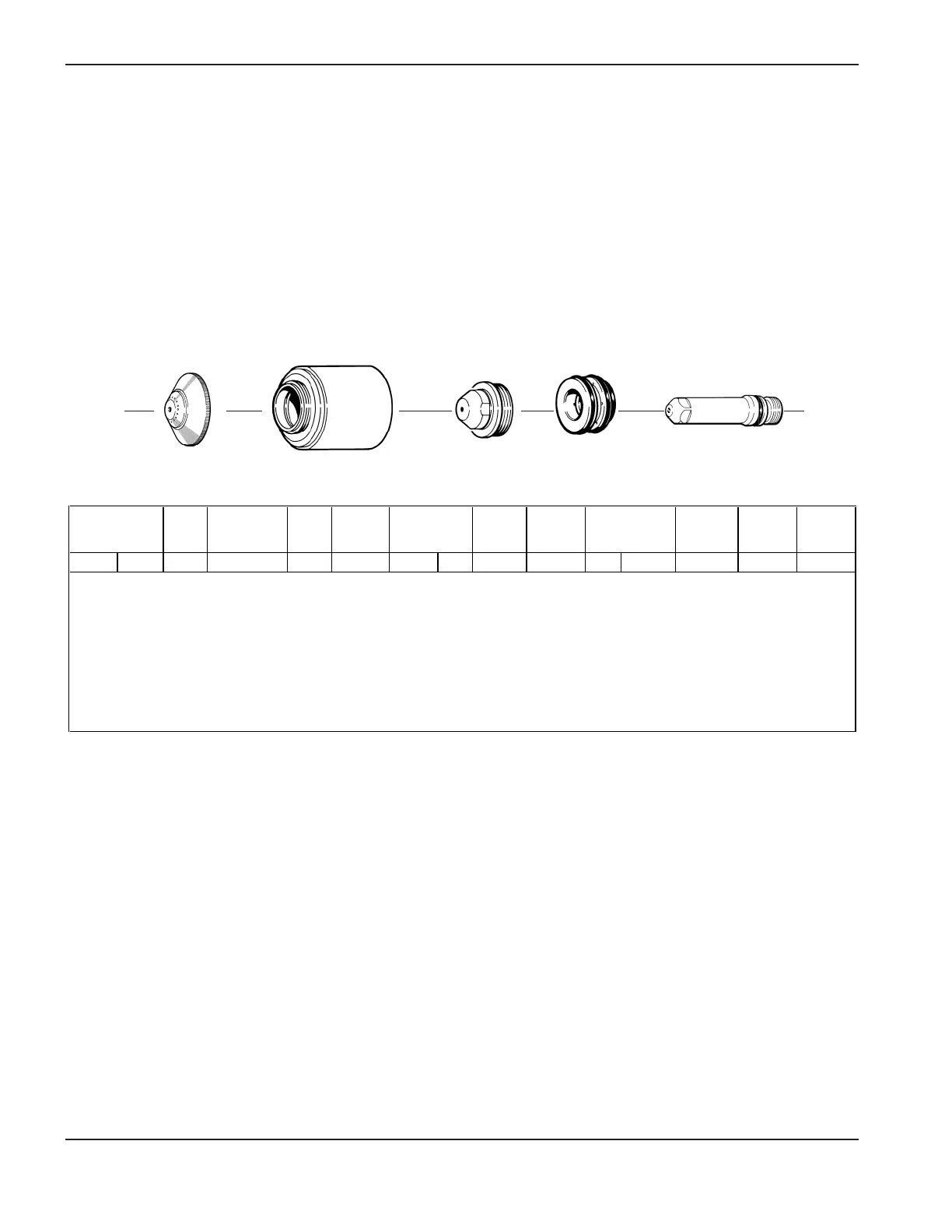

Shield

020611

Nozzle

020915

Retaining cap

120547

Electrode

020607

Swirl ring

Plasma

Gas

Type

Plasma Gas

Pressure

TEST/RUN

Shield

Gas

Type

Shield

Gas

Pressure

Arc

Current

Setting

Arc

Voltage

Setting

Approx.

Motion

Delay Time

Plasma

Gas Inlet

Pressure

Shield

Gas Inlet

Pressure

(Inches) (mm) (psi) (psi) (Inches) (mm) (amps) (volts) (ipm) (mm/min) (sec) (psi) (psi)

.075 2 Air 22-26* / 48-52 Air 60 5/64 2 80 120 6050 90 90

1/8 3 22-26* / 54-58 60 5/64 2 100 130 120 3050 0.5

3/16 5 1/8 3 130 100 2540 0.5

1/4 6 1/8 3 135 80 2030 0.5

3/8 10 1/8 3 140 50 1270 1.0

1/2 12 1/8 3 140 35 890 1.5

5/8 15 .157 4 145 25 635 2.0

3/4 20 3/16 5 150 20 510

Travel Speed

(37 SCFH) (270 SCFH)

Material

Thickness

Torch-to-work

Distance

Loading...

Loading...