www.hysecurity.com General Maintenance D0559 Rev. A 87

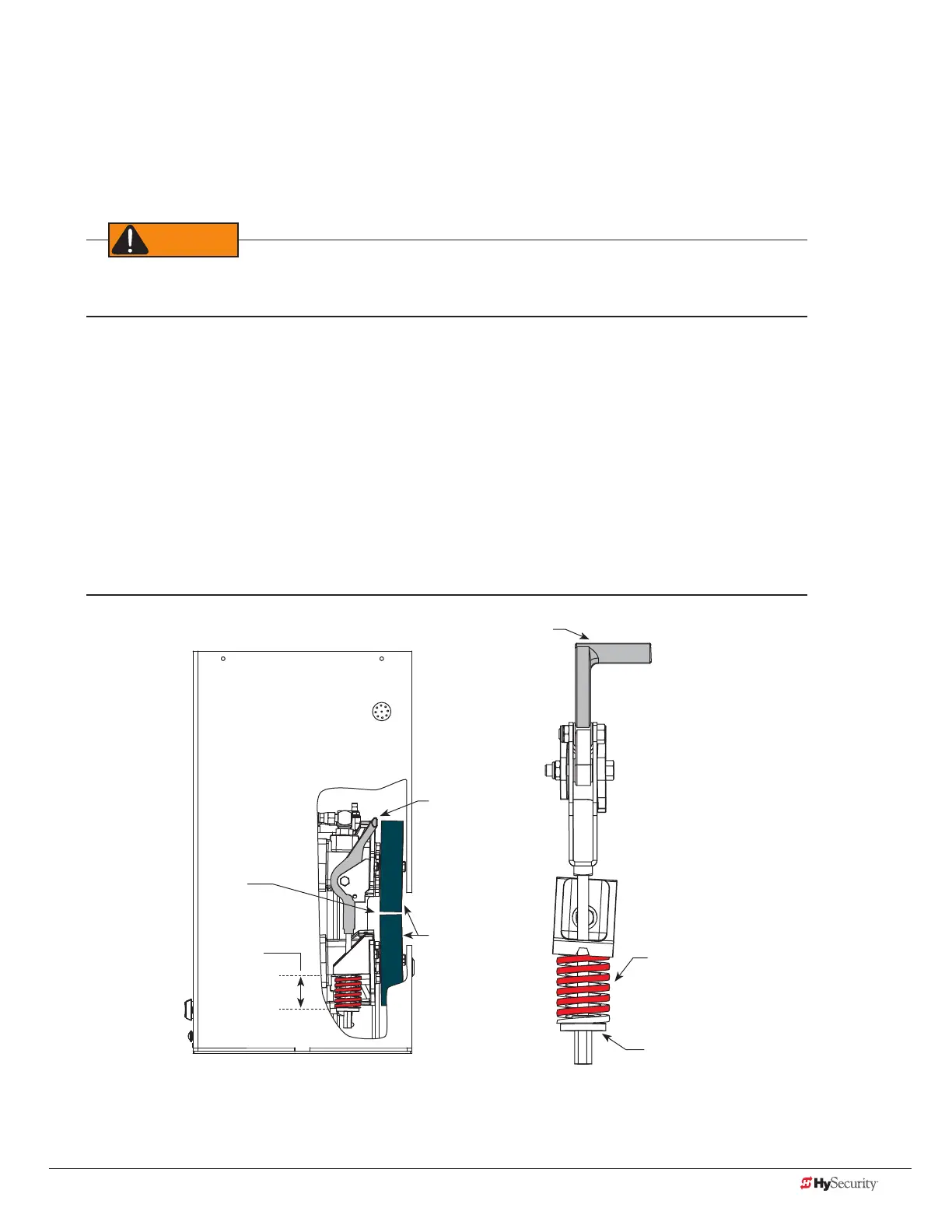

Drive Wheel Spring Tension (Adjustment of Manual Release)

All SlideDriver operators come equipped with a toggle handle manual release mechanism to disengage the drive

wheels from the drive rail.

During shipment, a piece of Styrofoam is placed between the coupling nut and the chassis. If the packaging is

still in place, discard it.

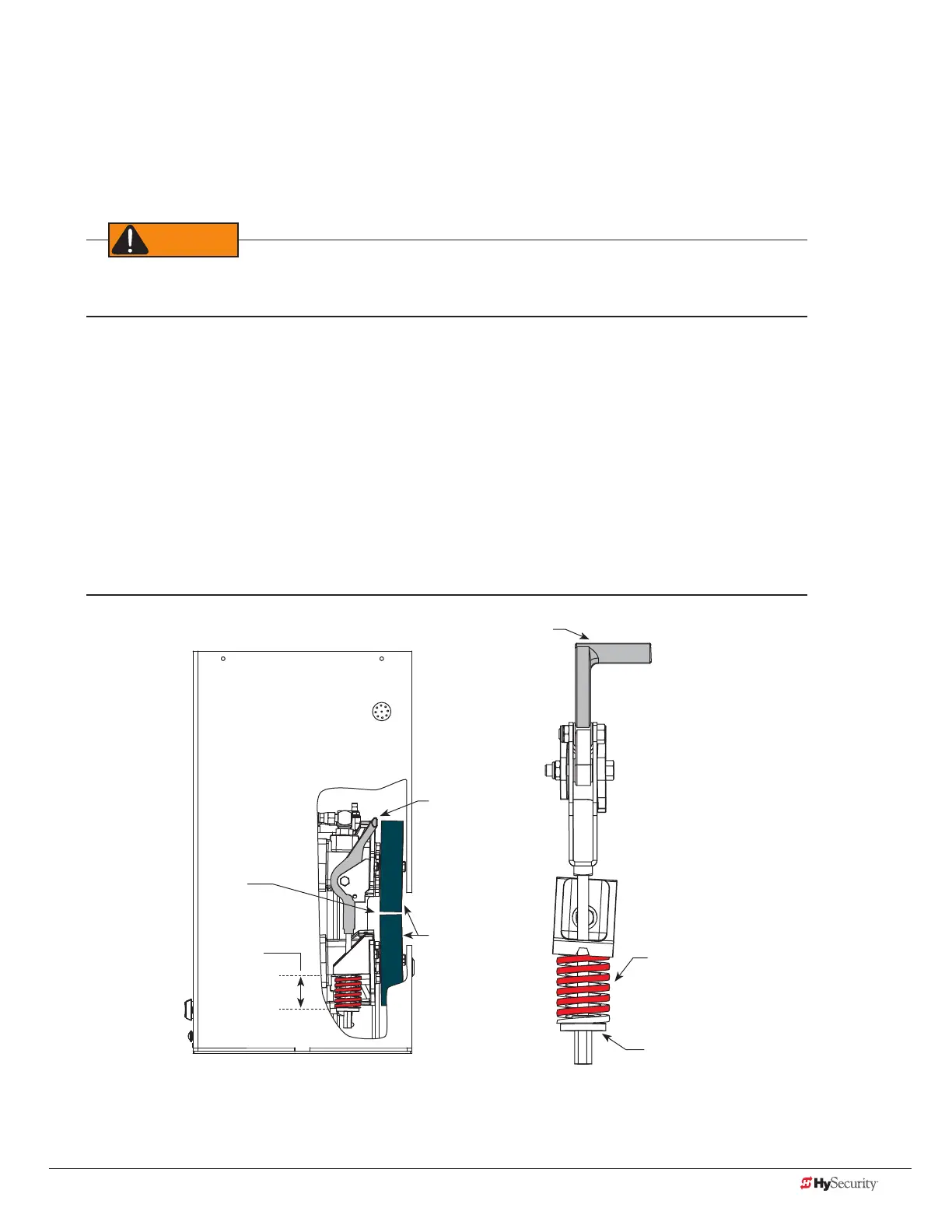

When releasing the handle inside the chassis, be careful as the mechanism is spring-loaded and drops rapidly.

Hold the toggle handle appropriately so your ngers do not get pinched, hit, or crushed.

To disengage the drive wheels, simply pull the aluminum toggle handle down. As the lower drive wheel drops

and disengages from the drive rail, it causes the coupling nut on the threaded rod to drop to its lowest position

and push on the base of the operator. This causes the upper drive wheel to lift and disengage from the drive rail.

The coupling nut must be adjusted correctly so the wheels provide a strong clamping force on the drive rail. The

red spring should measure 2 to 2⅛-inch (5 to 5.5cm) in height when under the correct compression.

NOTE: If the drive rail is installed at the correct height to the chassis, the toggle release mechanism spreads both

wheels equally in relation to the drive rail. If the drive rail has been mounted higher than specied, it may be

necessary to use an additional coupling nut and ⅜” bolt which can extend beyond the all thread and create

additional lift clearance for the upper drive wheel when the toggle handle is released. If this extension method is

used, adjust the ⅜” bolt so the drive wheels spread equally when they are fully disengaged.

2 to 21/8 ”

(5 to 5.4 cm)

Toggle handle

Red spring controls

wheel grip

Coupling Nut

for spring tension

adjustment

Toggle handle

Drive wheels

Drive rail slides

between drive

wheels

Loading...

Loading...