automatically

provides the carrier with the overbank

required for proper escapement pawl

re-entry

at

the

completion of a carrier return

operation.

5.

Clutch

Unlatching - With

either

style margin rack held

to

its extreme left position, the carrier return latch

keep-

er

should

clear

the latch by .005" to .015"

at

the

un-

latching point (Fig.

148).

Check

by manually holding

the

latch

at

the unlatching point whi

Ie

the machine

is

idling.

Lengthen or shorten the carrier return unlatching

I ink

to

obtain this

clearance.

NOTE: Should the clutch fail

to

properly latch (on

machines equipped with the

early

margin rack) after the

clutch unlatching adjustment has been completed,

check

the margin rack

eccentric

adjustment which

is

located

in the Margin

Control

section.

The

eccentric

may be

holding the rack too far to the left restricting the mar-

gin rack motion thereby reducing the amount of bite

that

the

latch

may take on the

keeper.

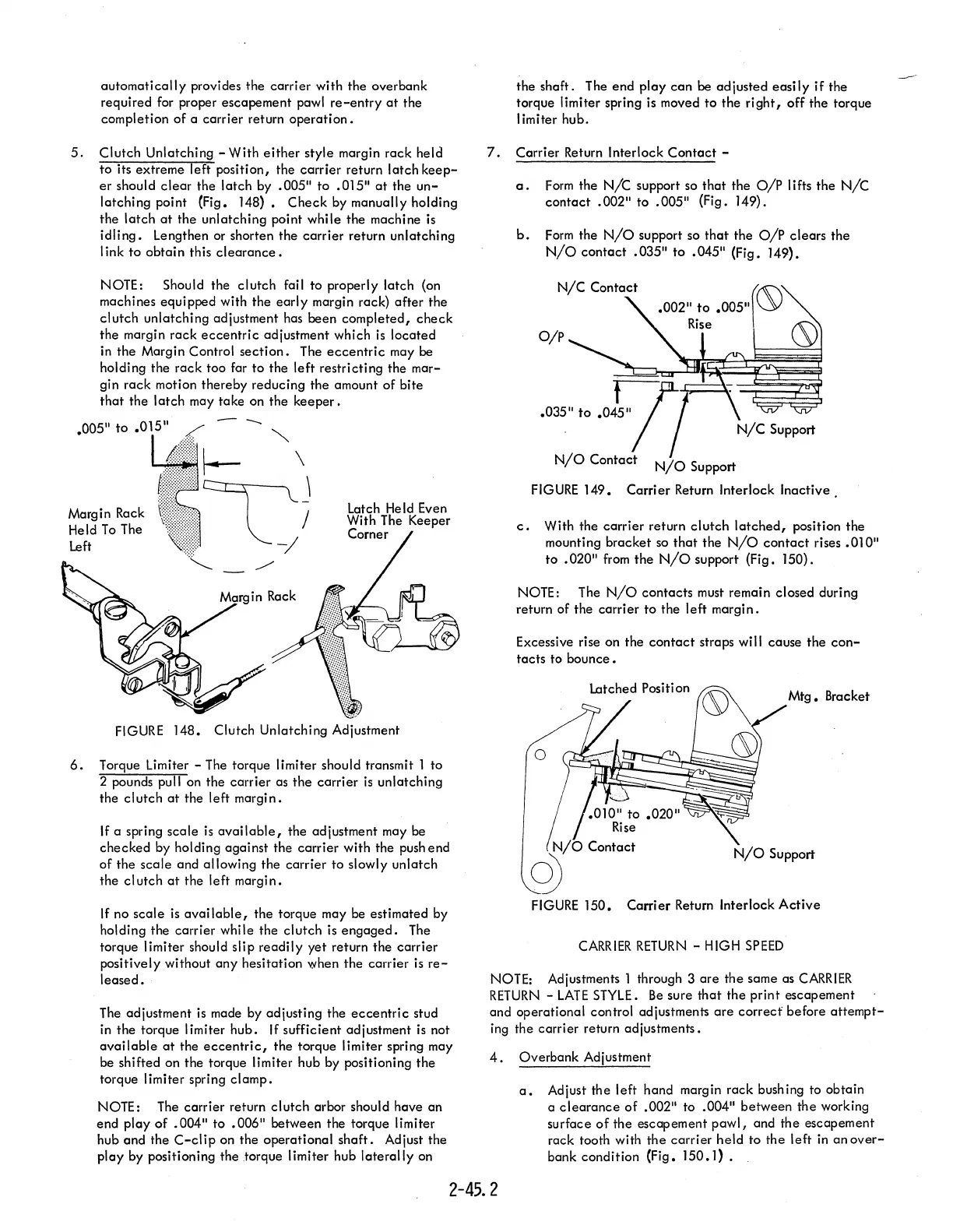

Margin Rack

Held

To

The

Left

---..

Latch Held Even

With The Keeper

Corner

FIGURE

148. Clutch Unlatching Adjustment

6;

Torque Limiter - The torque limiter should transmit 1 to

2 pounds pull on the carrier as

the

carrier

is

unlatching

the cl utch

at

the left margi

n.

If

a spring scale

is

available,

the adjustment may be

checked by holding against the carrier with the push end

of the scale and allowing the carrier

to

slowly unlatch

the

clutch

at

the left margin.

If

no scale

is

available,

the torque may be estimated by

holding the carrier while the

clutch

is

engaged.

The

torque limiter should slip

readily

yet return the carrier

positively without

any

hesitation when the carrier

is

re-

leased.

The adjustment

is

made by adjusting the

eccentric

stud

in

the torque limiter hub.

If

sufficient adjustment

is

not

available

at

the

eccentric,

the torque limiter spring may

be shifted on the torque limiter hub by positioning

the

torque limiter spring clamp.

NOTE: The carrier return

clutch

arbor should have an

end play

of

.004"

to

.006"

between the torque limiter

hub and the

C-clip

on the operational

shaft.

Adjust the

play by positioning the .torque limiter hub

laterally

on

the shaft. The end

play

can

be adjusted

easily

if

the

torque limiter spring

is

moved

to

the

right,

off the torque

limiter hub.

7.

Carrier Return Interlock

Contact

-

a.

Form

the

N/C

support so

that

the

O/P

lifts the

N/C

contact

.002"

to

.005"

(Fig. 149).

b.

Form

the

N/O

support so

that

the

O/P

clears the

N/O

contact

.035"

to

.045"

(Fig. 149).

N/C

Contact

.002"

to

.005"

(§)

Rise

O/p

N/O

Support

FIGURE

149.

Carrier Return Interlock Inactive

c.

With the carrier return

clutch

latched,

position the

mounting bracket

so

that

the

N/O

contact

rises

.010"

to

.020"

from

the

N/O

support (Fig. 150).

NOTE: The

N/O

contacts must remain closed during

return of the carrier

to

the left margin.

Excessive rise on the

contact

straps will cause the

con-

tacts to

bounce.

Mtg.

Bracket

o

.010"

to

.020"

~73I<§:;;;:J,

Rise

N/O

Contact

q)

FIGURE

150.

Carrier Return Interlock

Active

CARRIER

RETURN

- HIGH

SPEED

NOTE: Adjustments 1 through 3 are the same as

CARRIER

RETURN

-

LATE

STYLE.

Be

sure

that

the print escapement

and operational control adjustments

are

correcf

before

attempt-

ing the carrier return adjustments.

4.

Overbank Adjustment

a.

Adjust the left hand margin rack bushing to obtain

a

clearance

of

.002" to .004" between the working

surface

of

the escapement

pawl,

and the escapement

rack tooth with

the

carrier held to the left

in

an

over-

bank condition (Fig.

150.1)

•

2-45.2

Loading...

Loading...