Bushing

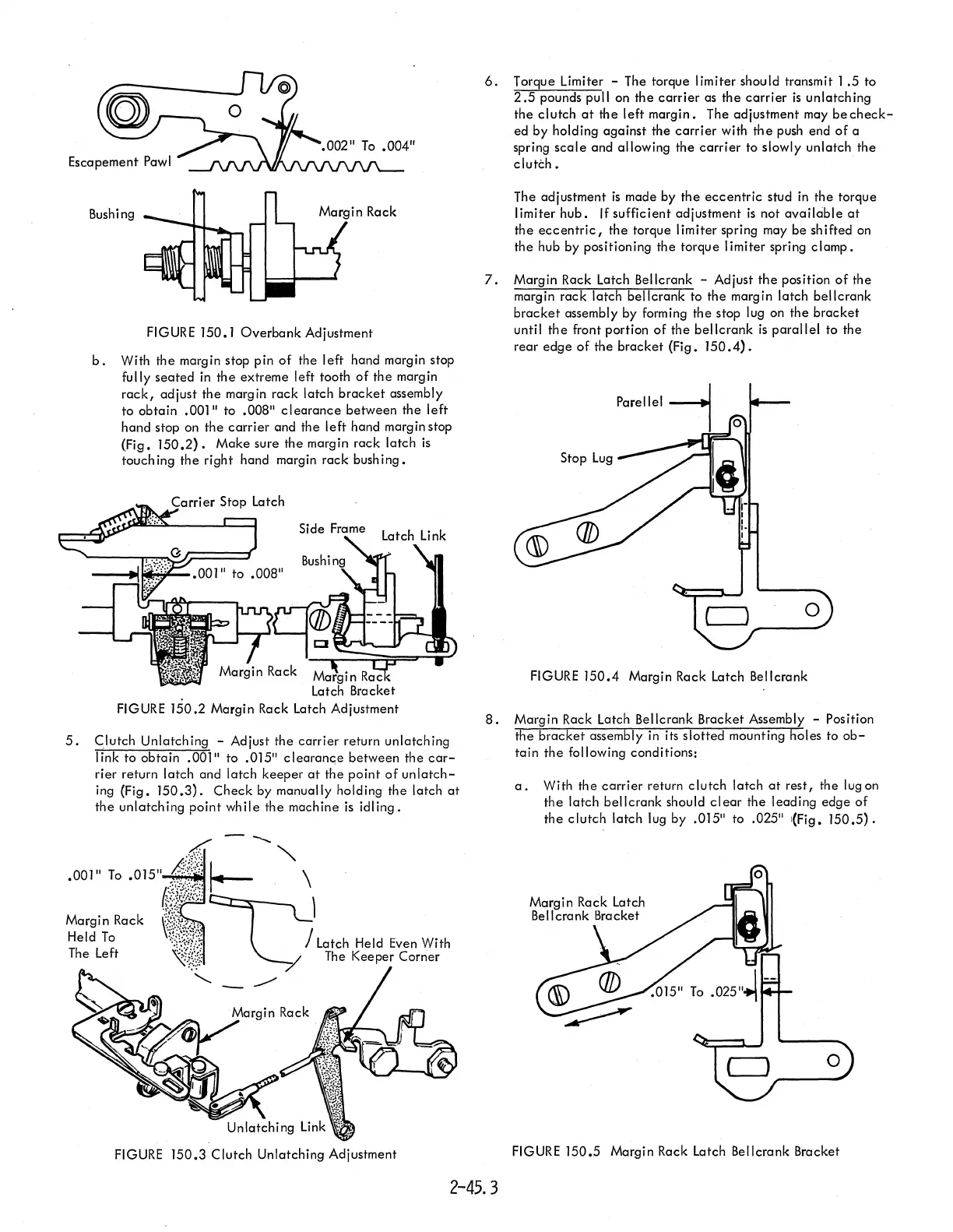

FIGURE 150.1

Overbank

Adjustment

b.

With

the

margin stop pin

of

the

left

hand margin stop

fully

seated

in

the

extreme left tooth

of

the

margin

rack,

adjust

the

margin

rack

latch

bracket

assembly

to

obtain

.001"

to

.008"

clearance

between

the

left

hand

stop on

the

carrier

and

the

left

hand margin stop

(Fig.

150.2).

Make

sure

the

margin

rack

latch

is

touching

the

right

hand margin

rack

bushing.

Bracket

FIGURE

150.2

Margin Rack Latch Adjustment

5.

Clutch

Unlatching - Adjust

the

carrier

return

unlatching

link

to

obtain

.001" to .015" clearanc;e

between

the

car-

rier

return

latch

and

latch

keeper

at

the

point

of

unlatch-

ing (Fig.

150.3).

Check

by manually holding

the

latch

at

the

unlatching

point

while

the

machine

is

idling.

FIGURE

150.3

Clutch

Unlatching Adjustment

6.

Torque Limiter - The torque limiter should transmit

1.5

to

2.5

pounds pull on

the

carrier

as

the

carrier

is

unlatching

the

clutch

at

the

left

margin.

The adjustment may

be

check-

ed

by

holding

against

the

carrier

with

the

push end

of

a

spring

scale

and allowing

the

carrier

to slowly

unlatch

the

clutch.

.

The adjustment

is

made by

the

eccentric

stud in

the

torque

limiter

hub.

If

sufficient

adjustment

is

not

available

at

the

eccentric,

the

torque I imiter spring may

be

sh

if

ted

on

the

hub by positioning

the

torque limiter spring

clamp.

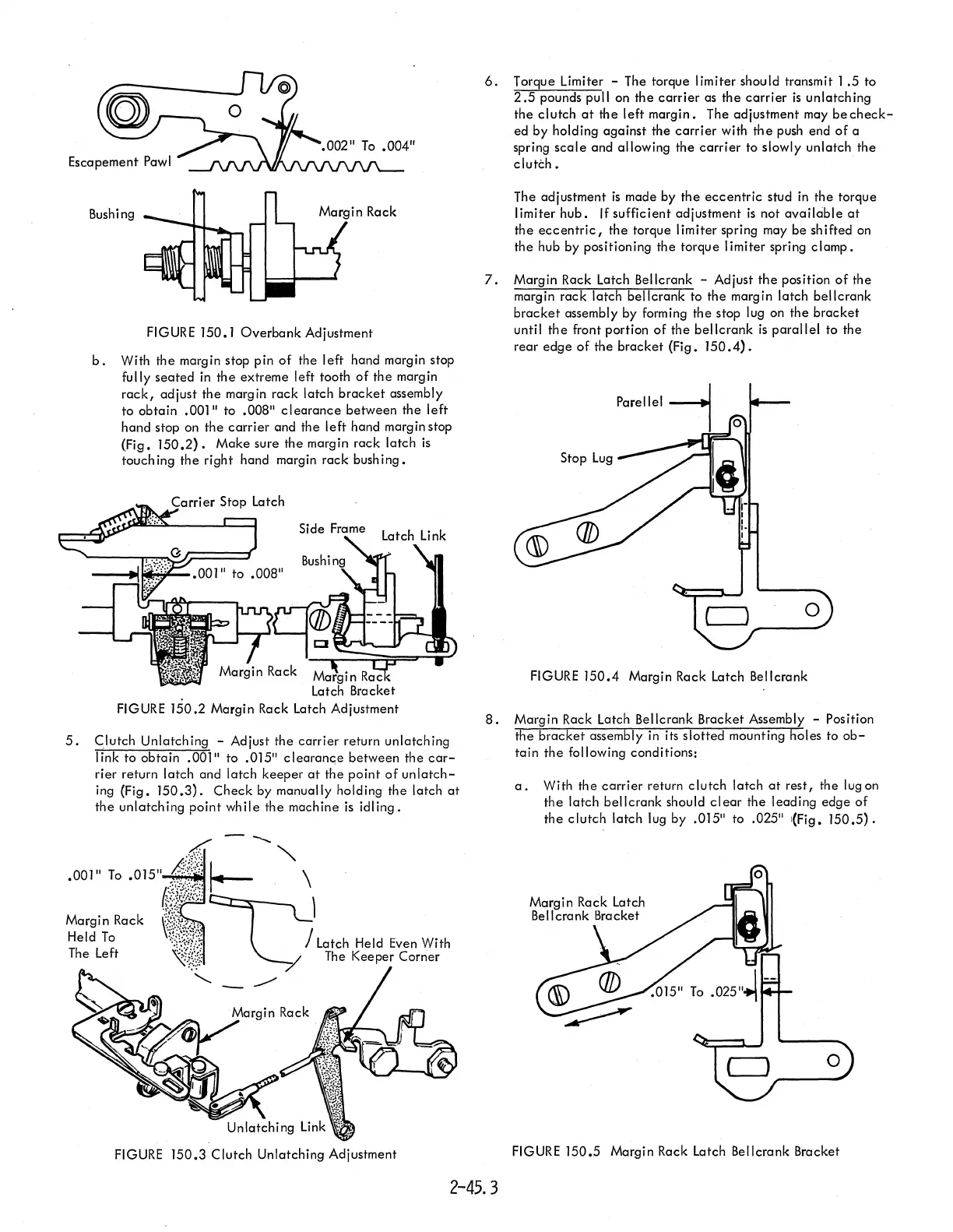

7.

Margin Rack Latch Bellcrank - Adjust

the

position

of

the

margin

rack

latch

bellcrank

to

the

margin latch

bellcrank

bracket

assembly by forming

the

stop lug on

the

bracket

until

the

front portion

of

the

bellcrank

is

parallel

to

the

rear

edge

of

the

bracket

(Fig.

150.4).

FIGURE

150.4

Margin Rack Latch Bellcrank

8.

Margin Rack Latch Bellcrank Bracket Assembly - Position

the

bracket

assembly in its

slotted

mounting holes to

ob-

tain

the

following conditions:

a.

With

the

carrier

return

clutch

latch

at

rest,

the lug on

the

latch

bellcrank

should

clear

the

leading

edge

of

the

clutch

latch

lug by .015" to .025" '(Fig.

150.5).

FIGURE

150.5

Margin Rack Latch Bellcrank Bracket

2-45.3

Loading...

Loading...