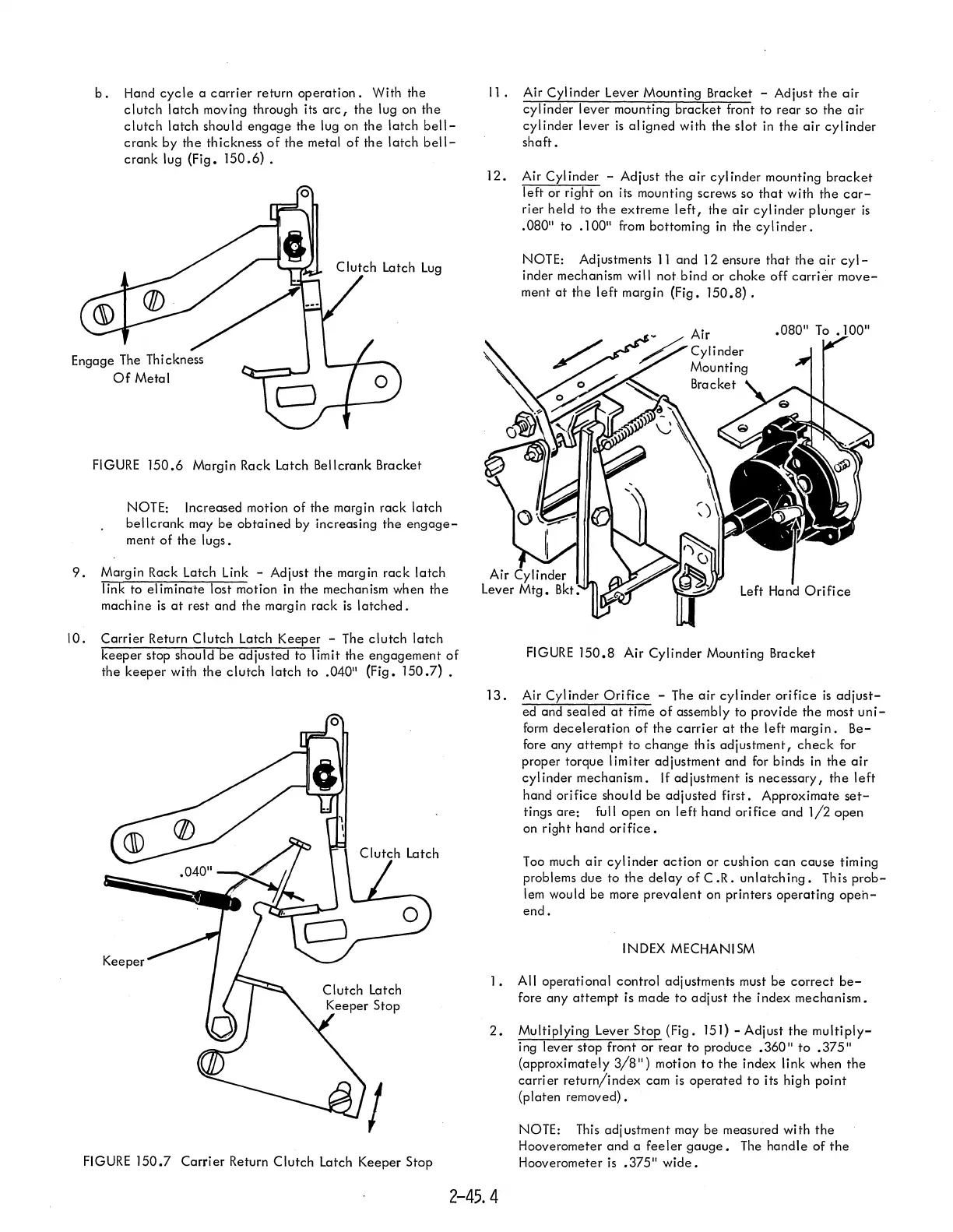

b.

Hand

cycle

a

carrier

return

operation.

With the

clutch

latch

moving through its

arc,

the

lug on

the

clutch

latch

should

engage

the

lug on

the

latch

bell-

crank

by

the

thickness

of

the

metal

of

the

latch

bell-

crank

lug

(Fig.

150.6) .

Engage The Thickness

Of

Metal

FIGURE

150.6 Margin Rack Latch Bellcrank Bracket

NOTE: Increased motion

of

the margin

rack

latch

bellcrank

may

be

obtained

by increasing

the

engage-

ment

of

the

lugs.

9.

Margin Rack Latch Link - Adjust

the

margin

rack

latch

I ink to el

iminate

lost motion in the mechanism when

the

machine

is

at

rest

and

the

margin

rack

is

latched.

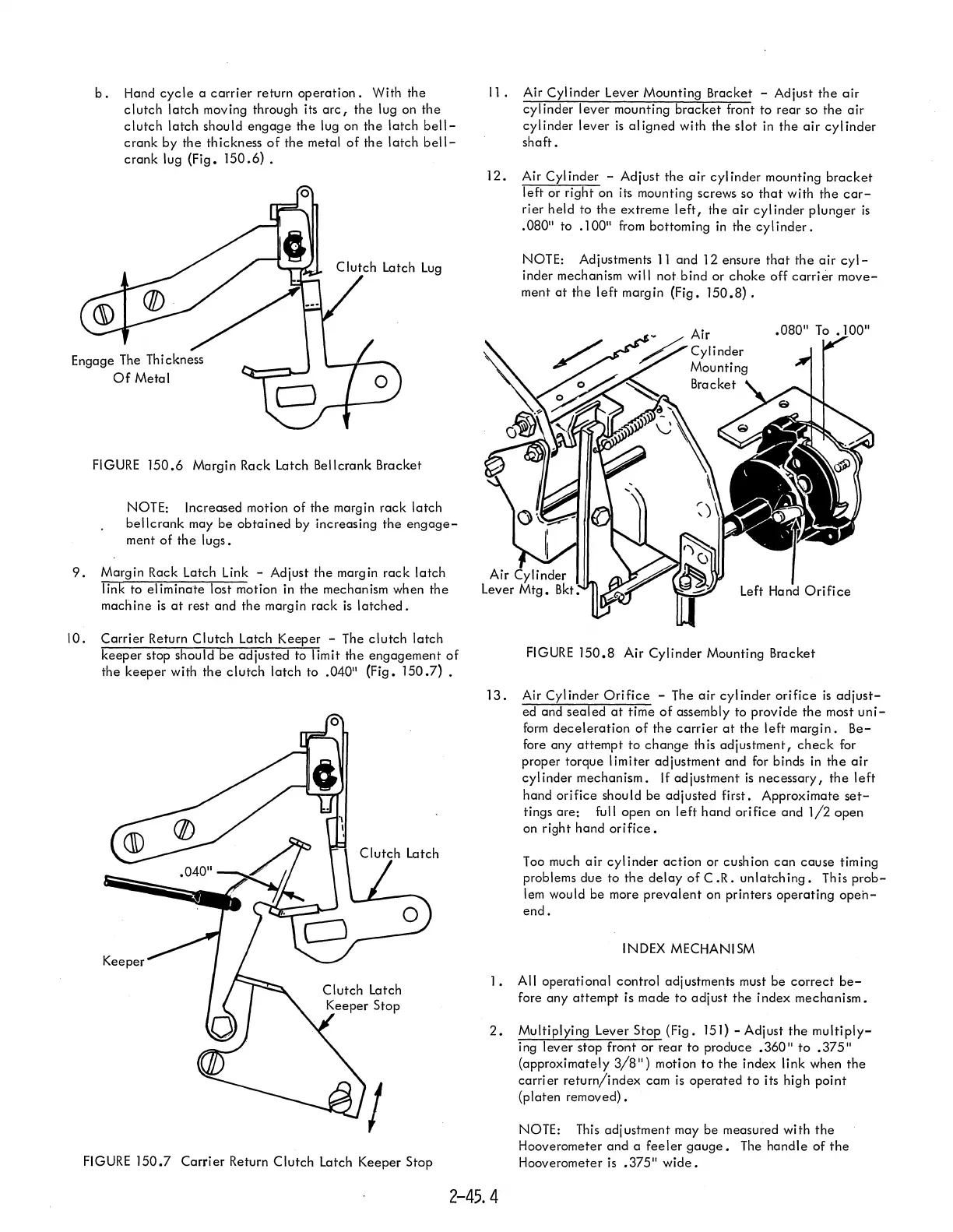

10.

Carrier

Return

Clutch

Latch Keeper - The

clutch

latch

keeper

stop should

be

adjusted

to I imit

the

engagement

of

the

keeper

with

the

clutch

latch

to .040"

(Fig.

150.7) .

11. Air

Cylinder

Lever Mounting Bracket - Adjust

the

air

cyl inder

lever

mounting

bracket

front

to

rear

so

the

air

cylinder

lever

is

aligned

with

the

slot

in

the

air

cylinder

shaft.

12. Air Cyl inder - Adjust

the

air

cyl inder mounting

bracket

left

or

right

on its mounting screws so

that

with

the

car-

rier

held

to

the

extreme

left,

the

air

cylinder

plunger

is

.080" to .100" from bottoming

in

the

cyl

inder.

NOTE: Adjustments

11

and

12 ensure

that

the

air

cyl-

inder mechanism will

not

bind

or

choke

off

carrier

move-

ment

at

the

left

margin (Fig.

150.8).

FIGURE

150.8

Air

Cylinder

Mounting Bracket

13.

Air

Cylinder

Orifice

- The

air

cylinder

orifice

is

adjust-

ed and

sealed

at

time

of

assembly to

provide

the

most

uni-

form

deceleration

of

the

carrier

at

the

left

margin.

Be-

fore any

attempt

to

change

th

is

adjustment,

check

for

proper torque

limiter

adjustment

and

for binds

in

the

air

cylinder

mechanism.

If

adjustment

is

necessary,

the

left

hand

orifice

should be

adjusted

first.

Approximate

set-

tings

are:

full

open

on

left

hand

orifice

and

1/2

open

on right

hand

orifice.

Too much

air

cylinder

action

or cushion

can

cause

timing

problems

due

to

the

delay

of

C.R.

unlatch

ing.

This

prob-

lem would be more

prevalent

on

printers

operating

opeh-

end.

INDEX MECHANISM

1.

All

operational

control

adjustments must be

correct

be-

fore

any

attempt

is made

to

adjust

the

index

mechanism.

2.

Multiplying Lever

Stop

(Fig.

151)

- Adjust

the

multiply-

ing

lever

stop front

or

rear

to

produce .360"

to

.375"

(approximately

3/8")

motion

to

the

index link

when

the

carrier

return/index

cam

is

operated

to

its high

point

(platen

removed).

NOTE: This

adjustment

may be measured

with

the

Hooverometer

and

a

feeler

gauge.

The

handle

of

the

FIGURE 150.7

Carrier

Return

Clutch

Latch

Keeper

Stop Hooverometer

is

.375"

wide.

2-45.4

Loading...

Loading...