18

Carry out a tank adjustment with empty tank, if possible, to cover any

possible interfering sources� In this case:

► Select the max� adjustment distance (L - 250 mm)�

If the tank cannot be emptied, adjustment to a partly filled tank is possible�

In this case:

► Observe the safety distance (b)�

Only if data storage is required in an IO-Link application:

The tank adjustment is not saved via IO-Link� After a replacement it must

be carried out again�

More information about data storage: (→ 16.2)�

7.2 Probe installation

The probe is not supplied (→ 3 Items supplied).

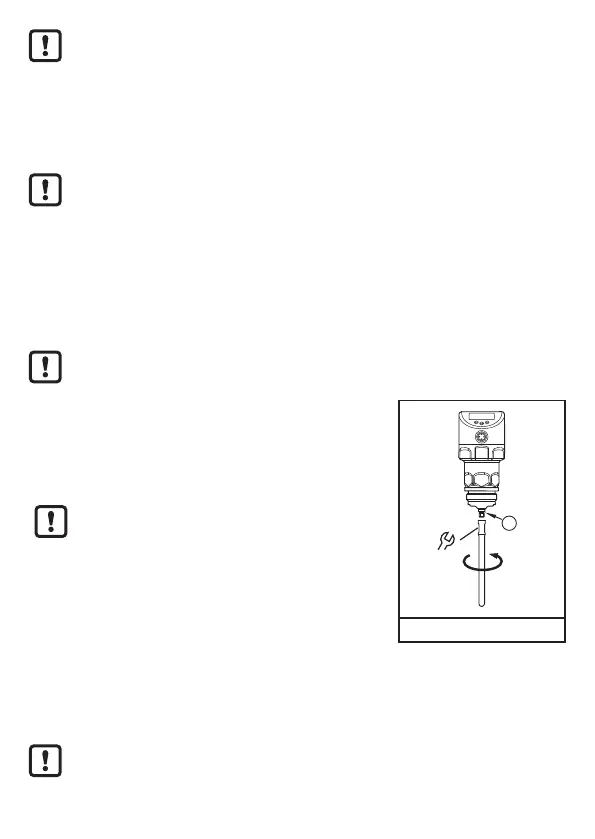

7.2.1 Attaching the probe

Do not damage the surfaces of the process connection and the probe�

► Use suitable tools with plastic surfaces�

Fixing of the probe:

► Remove the protective cover / protective devices

from the unit and the probe�

► Screw the probe to the unit and tighten it�

Recommended tightening torque: 6�5 Nm�

► Check the correct position of the O-ring at the probe

attachment point (1)� Replace if damaged�

1

8

(1) O-ring

For secondary processes:

In case of high mechanical stress (strong vibration, moving viscous media) it

may be necessary to secure the screw connection, e�g� by a screw retaining

compound�

Substances such as screw retaining compounds may migrate into the

medium�

► Make sure that they are harmless�

Loading...

Loading...