86 A20733 B0

Servicing

3.2.2 Rinse the conduit and head assembly

Circulating clean additive through all pipes in the head and conduit ensures that they are

perfectly clean and guarantees that the printer can be restarted easily after being shut down for

between one and two weeks.

The procedure is as follows:

1- With the printer running and the jet idle, make the machine take in additive from the

recuperation gutter for 20 seconds.

2- Stop the printer.

3- Close the recuperation gutter.

4- Uncouple the pressure connector in the hydraulic compartment.

5- Connect the rinsing connector (1) to the conduit pressure pipe next to the head filter.

6- Immerse the free end of the rinsing connector in a beaker of additive or in the printer’s

additive tank.

7- Block the nozzle with an anti-clogging protector.

8- Start up the printer and enable the [Refresh] function for around 30 seconds.

9- Enable the [Nozzle unblocking] function for around 20 seconds.

10- Shut down the printer and wait for it to stop completely.

11- Restore the initial hydraulic connections.

(1)

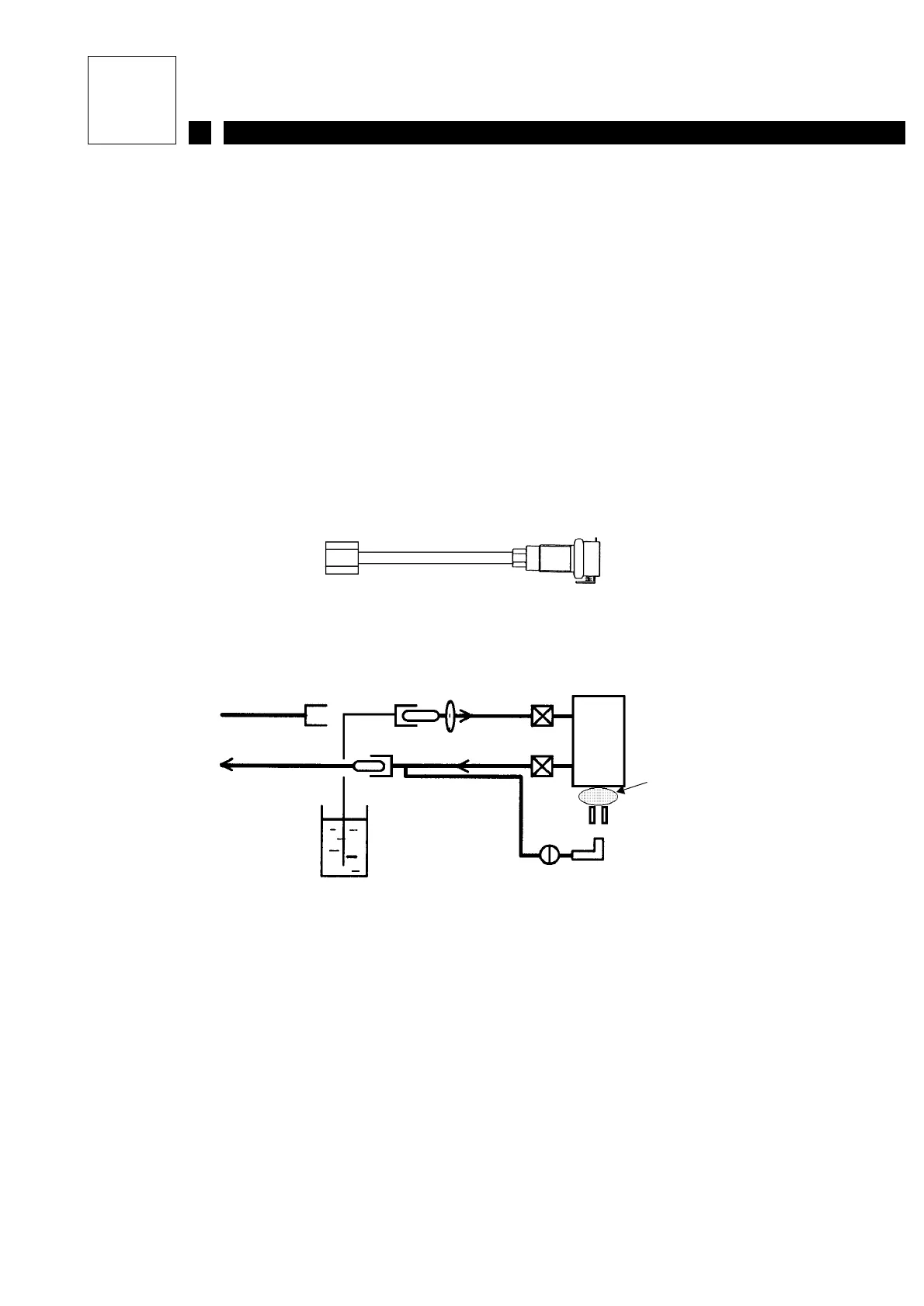

Ink circuit Pressure(1)

Drain

Cannon

Anti-clogging protector

Recuperation gutter

Beaker of additive or

printer additive tank

pressure

Loading...

Loading...