86

INSTALLER

USERMAINTENANCE TECHNICIAN

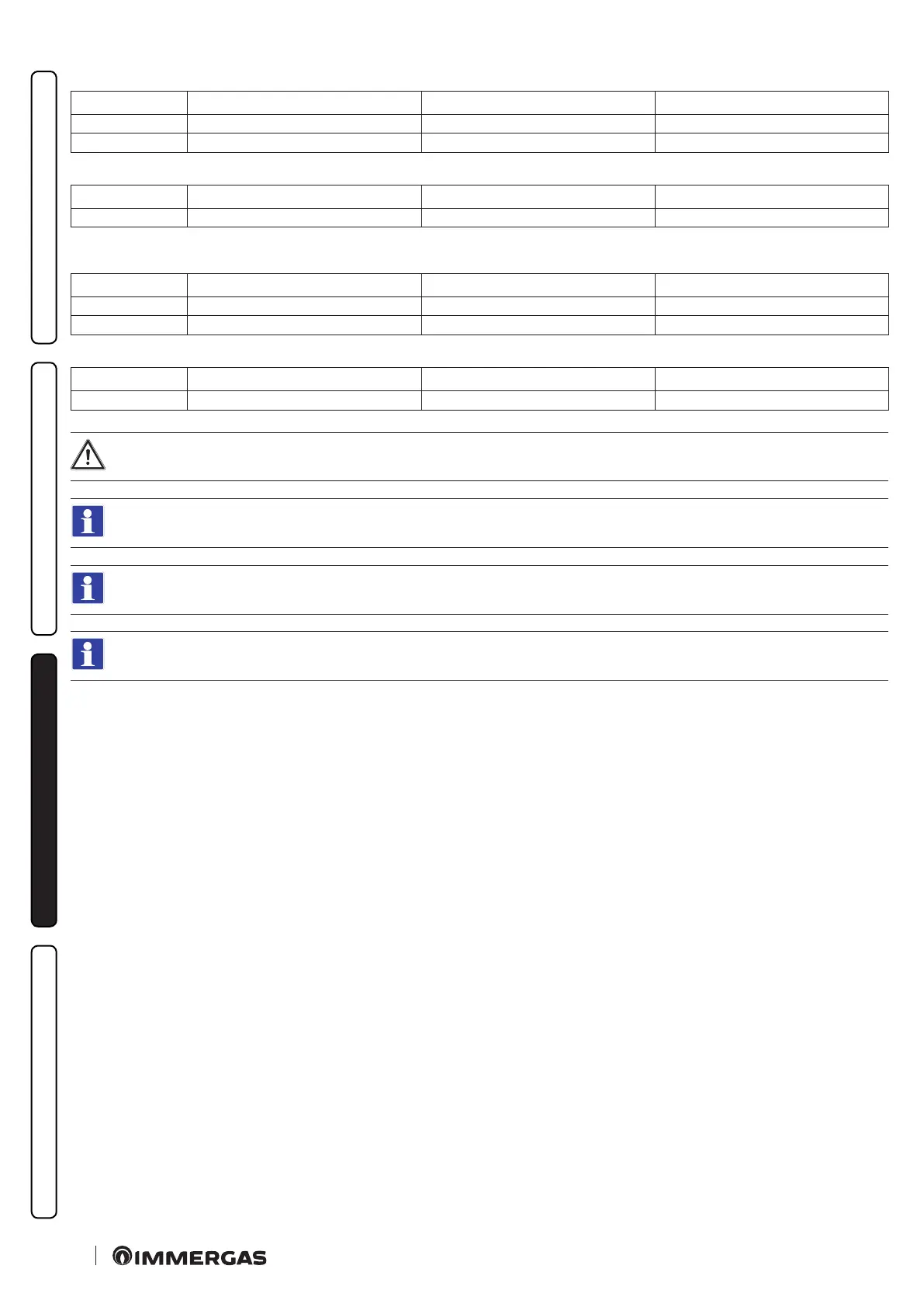

TECHNICAL DATA

Victrix Tera V2 24 Plus EU

Gas type CO

2

to nominal Q. CO

2

to ignition Q. CO

2

to minimum Q.

G20 9,2 (9,1 ÷ 9,5) % 9,1 (9,0 ÷ 9,4) % 8,5 (8,3 ÷ 8,7) %

G31 10,2 (10,0 ÷ 10,4) % 10,2 (10,0 ÷ 10,4) % 9,7 (9,5 ÷ 9,9) %

Gas type O

2

at Nominal Q. O

2

at Ignition Q. O

2

at Minimum Q.

G20 4,4 (4,6 ÷ 3,9) % 4,6 (4,8 ÷ 4,1) % 5,7 (6,0 ÷ 5,3) %

Victrix Tera V2 35 Plus EU

Gas type CO

2

to nominal Q. CO

2

to ignition Q. CO

2

to minimum Q.

G20 9,0 (8,9 ÷ 9,3) % 9,0 (8,9 ÷ 9,3) % 8,5 (8,2 ÷ 8,6) %

G31 10,2 (10,1 ÷ 10,4) % 10,2 (10,0 ÷ 10,4) % 9,6 (9,4 ÷ 9,8) %

Gas type O

2

at Nominal Q. O

2

at Ignition Q. O

2

at Minimum Q.

G20 4,8 (5,0 ÷ 4,2) % 4,8 (5,0 ÷ 4,2) % 5,7 (6,2 ÷ 5,5) %

If a Hydrogen ready installation is planned for H

2

percentages up to 20%, (referring to the gas distributed in the network accord-

ing to local standards in force) all calibration of the unit must refer to the O

2

values in the table above.

In addition to yearly maintenance, one must also check the energy eciency of the thermal system, with frequency and proce-

dures that comply with the indications of the technical regulations in force.

When adjusting nominal heat input, if the O

2

values are not reached with the gas ow regulator completely open, no further

adjustments are required.

In the case of an annual inspection of the device, the max CO must be less than 700 ppm (0% O

2

). If the CO value is higher, the

device requires maintenance/repair.

Loading...

Loading...