TechDoku_CC1000_VCC1000_CC3000_VCC3000_GenPM_GB_860

25010_86025110.doc

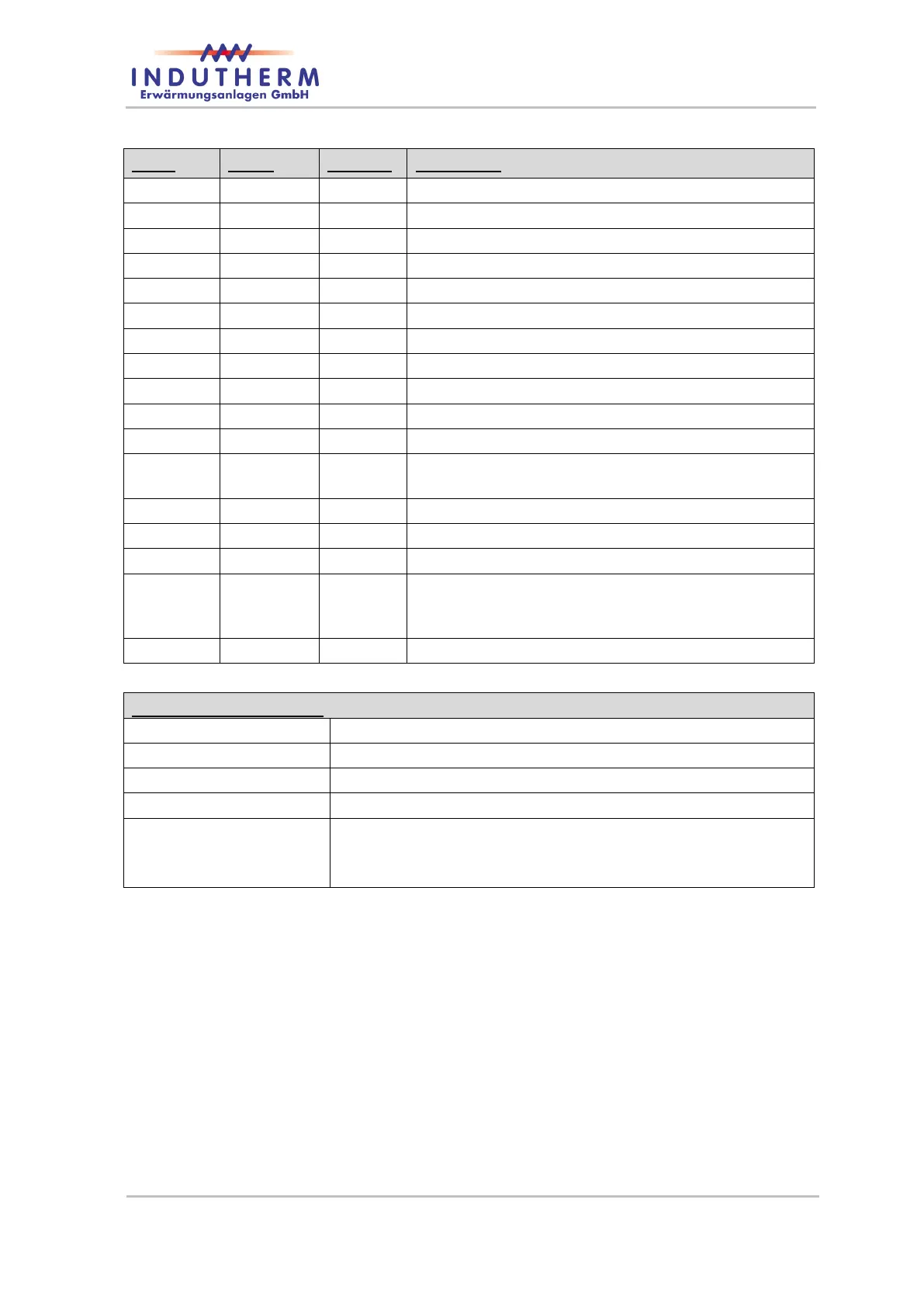

rotation speed of roll in draw direction

draw length in millimetre

rotation speed in reverse direction

reverse length in millimetre, less than draw length

reverse stop time in seconds

actual heating power in kW

actual power consumption in the die kW

behind die temperature (z. B. 100 °C if waterflow or

watertemperature is selected on the left side)

pressure inside melting chamber in bar

actual drawing force in Newton

actual reverse force in Newton

selected program

programs over 79 are for the options granulat-

ing/sintering – available with selector key

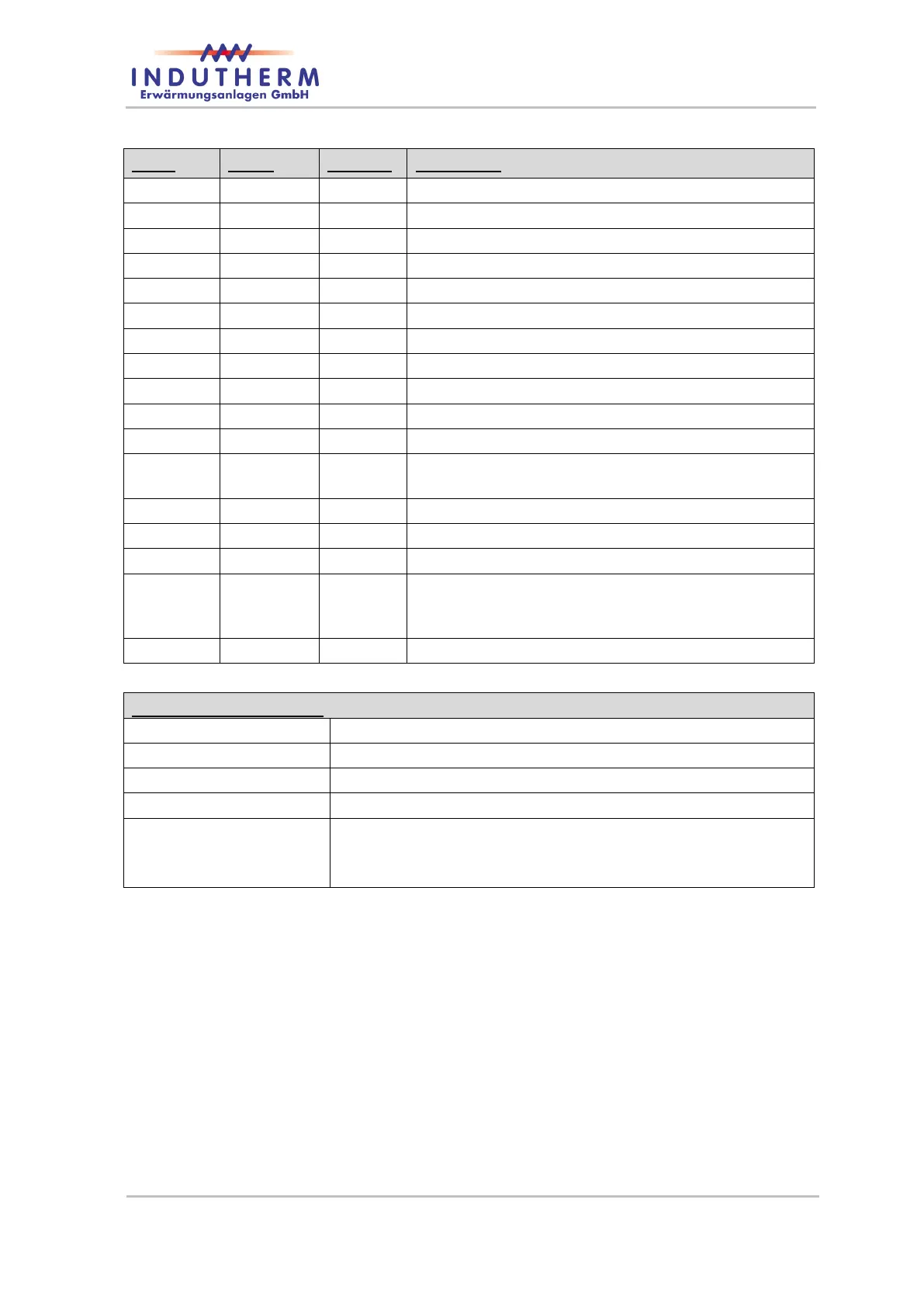

Display in the lower area:

moves the input mask one field above

moves the input mask one field down

decrease the selected value

increase the selected value

“<>” go to the left or right digit in the selected input mask

which would be highlighted.

“INFO” shows you information about CC-process

Loading...

Loading...