11

trapuls – EtherCAT® Fieldbus Interface

Chapter 4 – Specifications of the SDOs and PD0s for the EtherCAT®

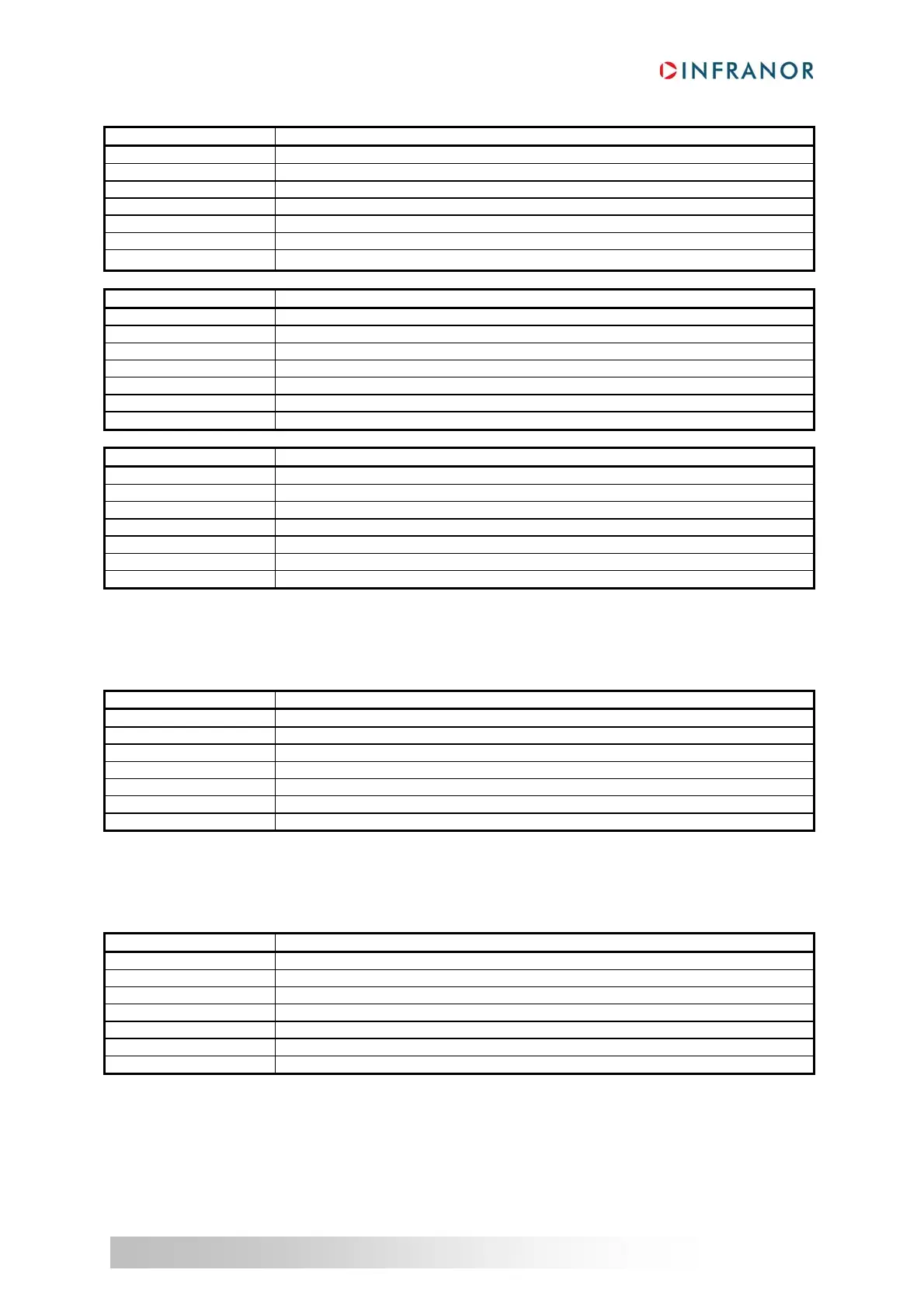

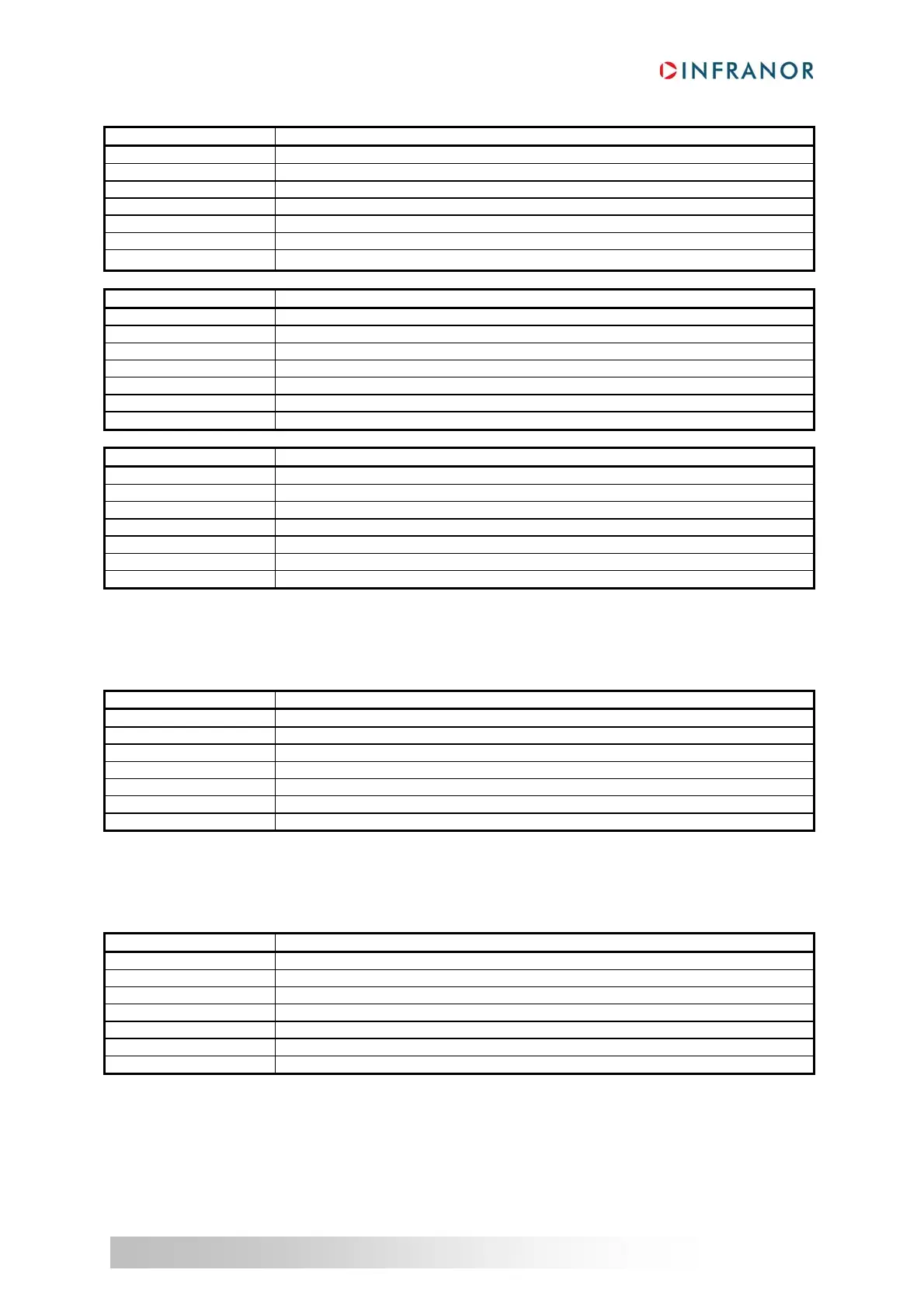

Sub Index 2

Name Communication type Sync Manager channel 2

Object Code VAR

Data Type Integer8

Object Class all

Access ro

PDO Mapping No

Default Value 2 : mailbox send (slave to master)

Sub Index 3

Name Communication type Sync Manager channel 3

Object Code VAR

Data Type Integer8

Object Class all

Access ro

PDO Mapping No

Default Value 3 : process data output (master to slave)

Sub Index 4

Name Communication type Sync Manager channel 4

Object Code VAR

Data Type Integer8

Object Class all

Access ro

PDO Mapping No

Default Value 4 : process data input (slave to master)

4.1.2 – SYNC MANAGER CHANNEL 0 PDO ASSIGNMENT

Value description

Index 0x1C10

Name Sync Manager channel 0 PDO assignment

Object Code VAR

Data Type Integer8

Object Class all

Access ro

PDO Mapping No

Default Value 0 : no PDO assigned

4.1.3

– SYNC MANAGER CHANNEL 1 PDO ASSIGNMENT

Value description

Index 0x1C11

Name Sync Manager channel 1 PDO assignment

Object Code VAR

Data Type Integer8

Object Class all

Access ro

PDO Mapping No

Default Value 0 : no PDO assigned

Loading...

Loading...