LP600 Users Manual

Rev E, February 2017

Page 27 of 43

Procedure: Calibration (Adjustment)

Tools required:

Calibration force generator; press or deadweights. This calibration source must

cover the range of 10% to 100% of nominal scale capacity with a certified accuracy

of 0.025% of reading or better.

100267 - 10" ( 0.25") x 17" ( 0.25") x 1.75" (minimum) aluminum loading block.

100268-A - 10" ( 0.25") x 17" ( 0.25") x 0.5" ( 0.125") rubber loading scale. (40 to

70 Shore A rating)

140208 - #2 Phillips screwdriver.

140210 - Static dissipation station.

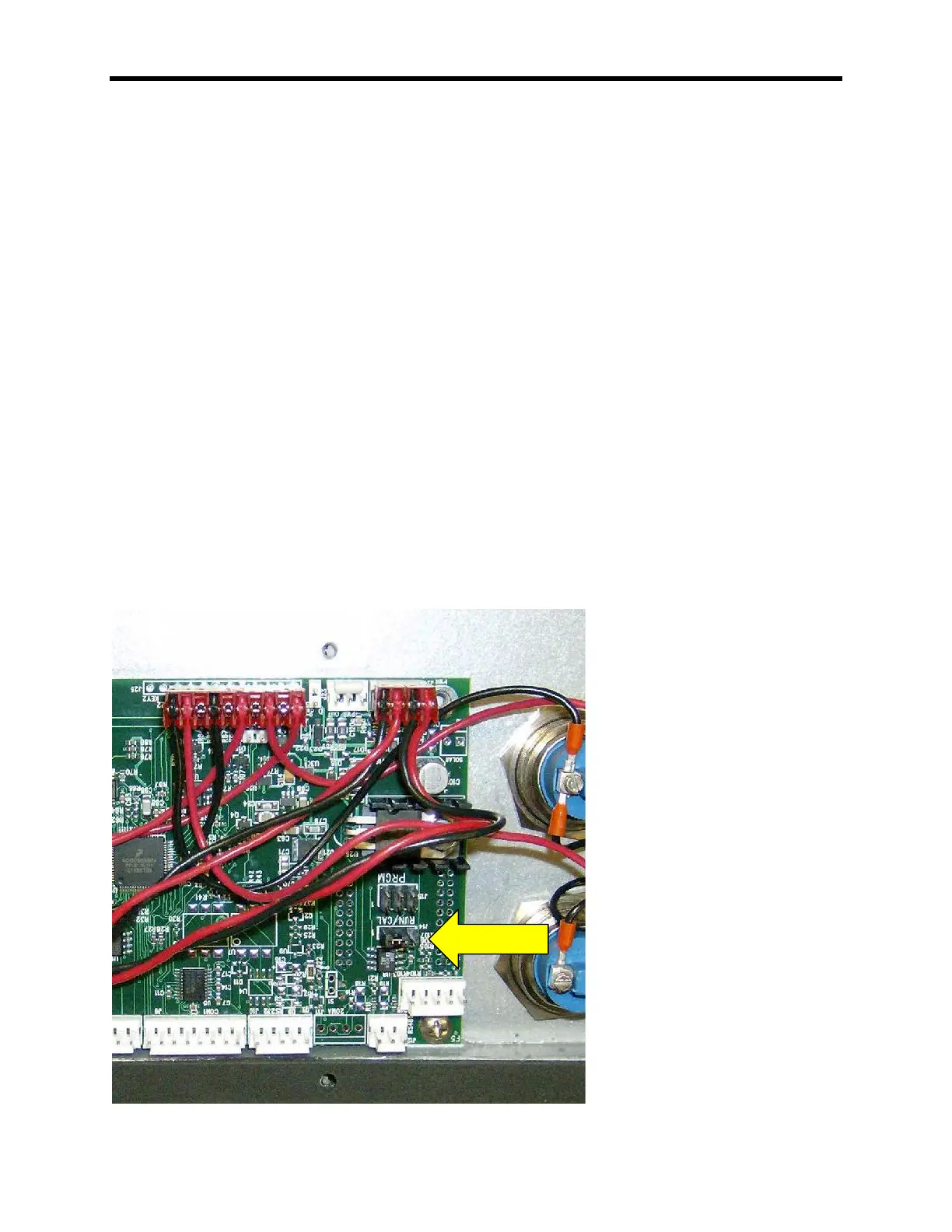

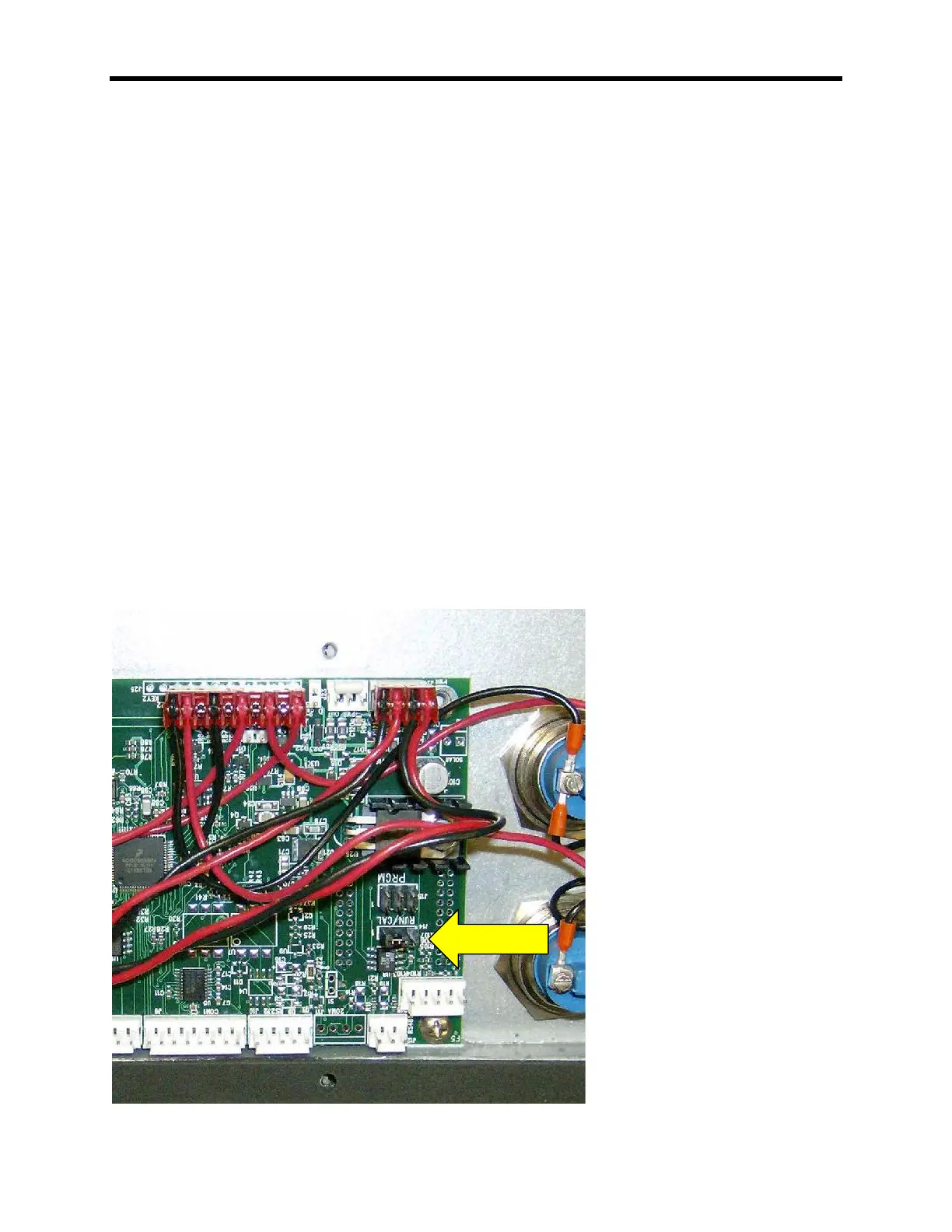

Calibration Enable Jumper

To access the calibration mode the shorting strap labeled “RUN/CAL”, located on the

right-middle of the circuit board (Intercomp, A/D 20 BIT rev E), it must be moved from

shorting pins 2 and 3(RUN); to shorting pins 1 and 2(CAL). To access the shorting

strap, remove the 10 screws on the outside edges of the display assembly. Carefully lift

the display assembly up and place the assembly, display side down, on top of the

weighing platform.

Note: Care must be taken to ensure the wire harness is seated properly to

prevent it from being pinched between the display assembly and the scale

casing.

Loading...

Loading...