LP600 Users Manual

Rev E, February 2017

Page 24 of 43

Calibration

Notice: The LP600 scale is calibrated by the factory prior to shipment.

Note: If the LP600 scale is calibrated using dead weights the correct altitude and

latitude must be set. If it is calibrated using a force calibration press the altitude must be

set to 0 feet and the latitude set to 45 degrees.

Note: The calibration will achieve the best accuracy if calibration loads are applied to

LP600 platform through a metal block, separated from the platform by a thick piece of

firm rubber; this setup best simulates the load applied by a tire. Loading without a block

can damage the scale. See Tool List below for complete specifications.

Procedure: Calibration (Verification)

Tools required:

Calibration force generator; press or deadweights. This calibration source must

cover the range of 10% to 100% of nominal capacity with an accuracy of 0.025% of

reading or better.

100267 - 10" ( 0.25") x 17" ( 0.25") x 1.75" (minimum) aluminum loading block.

100268-A - 10" ( 0.25") x 17" ( 0.25") x 0.5" ( 0.125") rubber loading scale. (40 to

70 Shore A rating)

1. Bring the scales to the calibration site. If there is more than 5F difference in

temperature between the scale temperature and the calibration site allow the scales

to reach room temperature.

2. Place scale on calibration fixture.

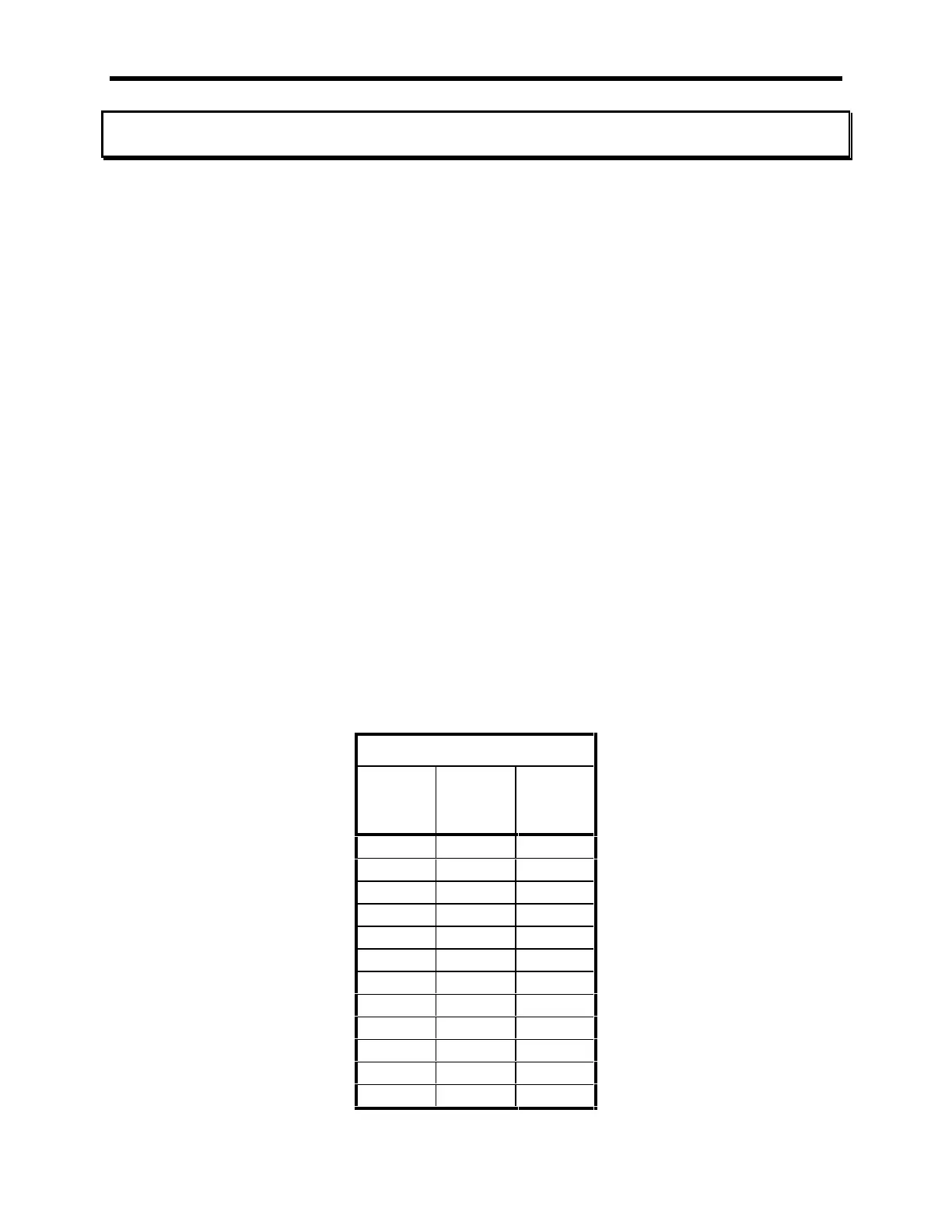

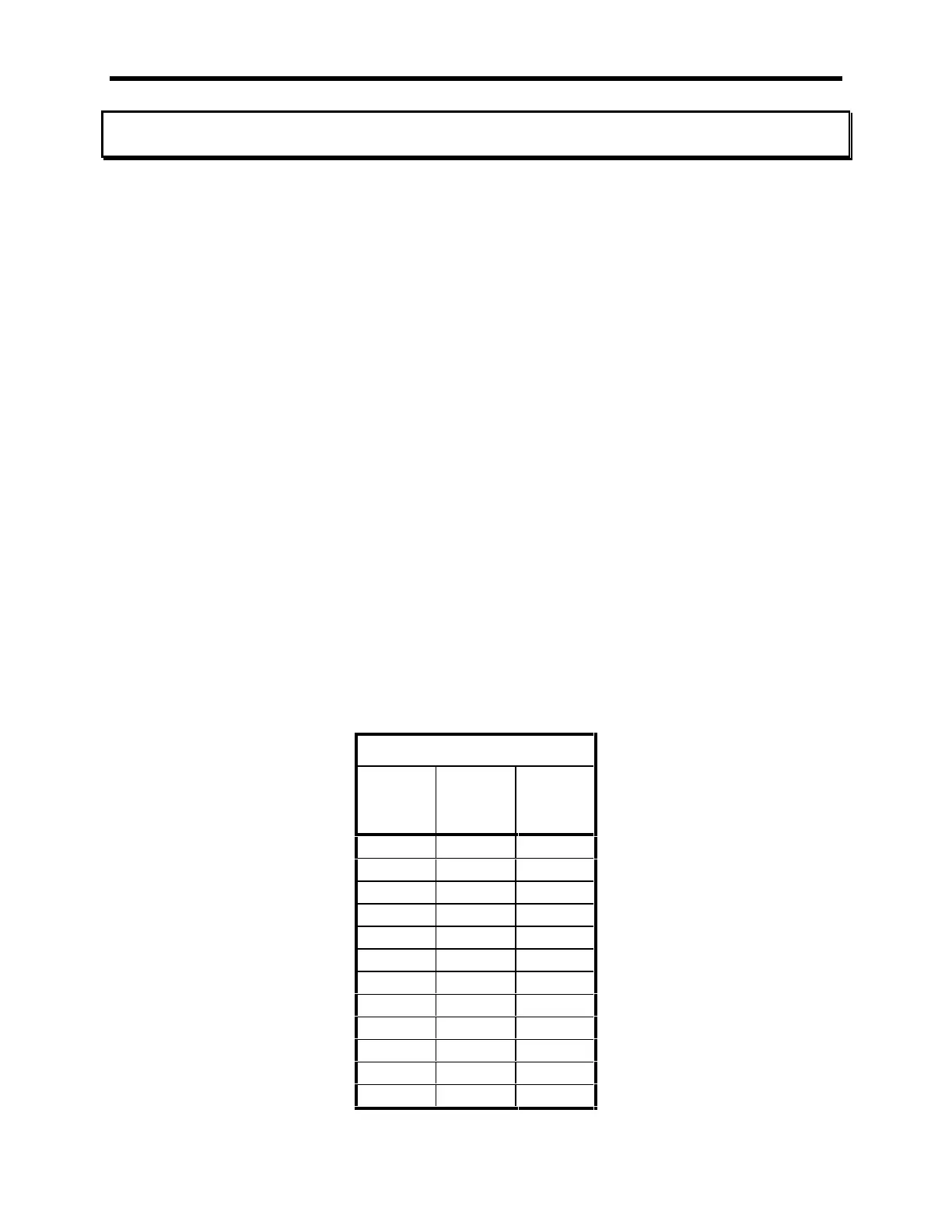

3. Using the following table, apply the specified test forces:

4. Verify that each display value is within the limits shown.

Loading...

Loading...