36 Intermec EasyCoder PC4—Service Manual

Chapter 5—Base Frame

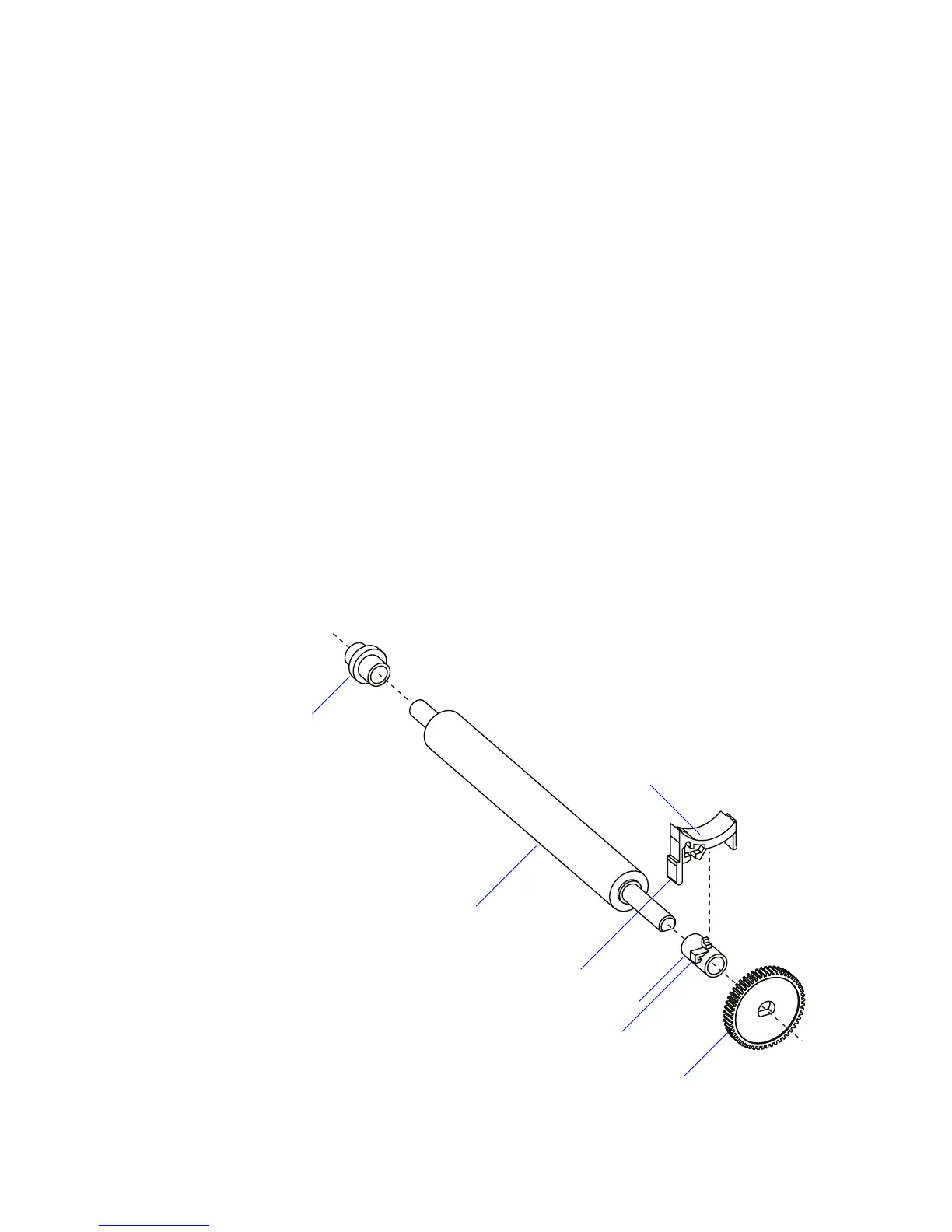

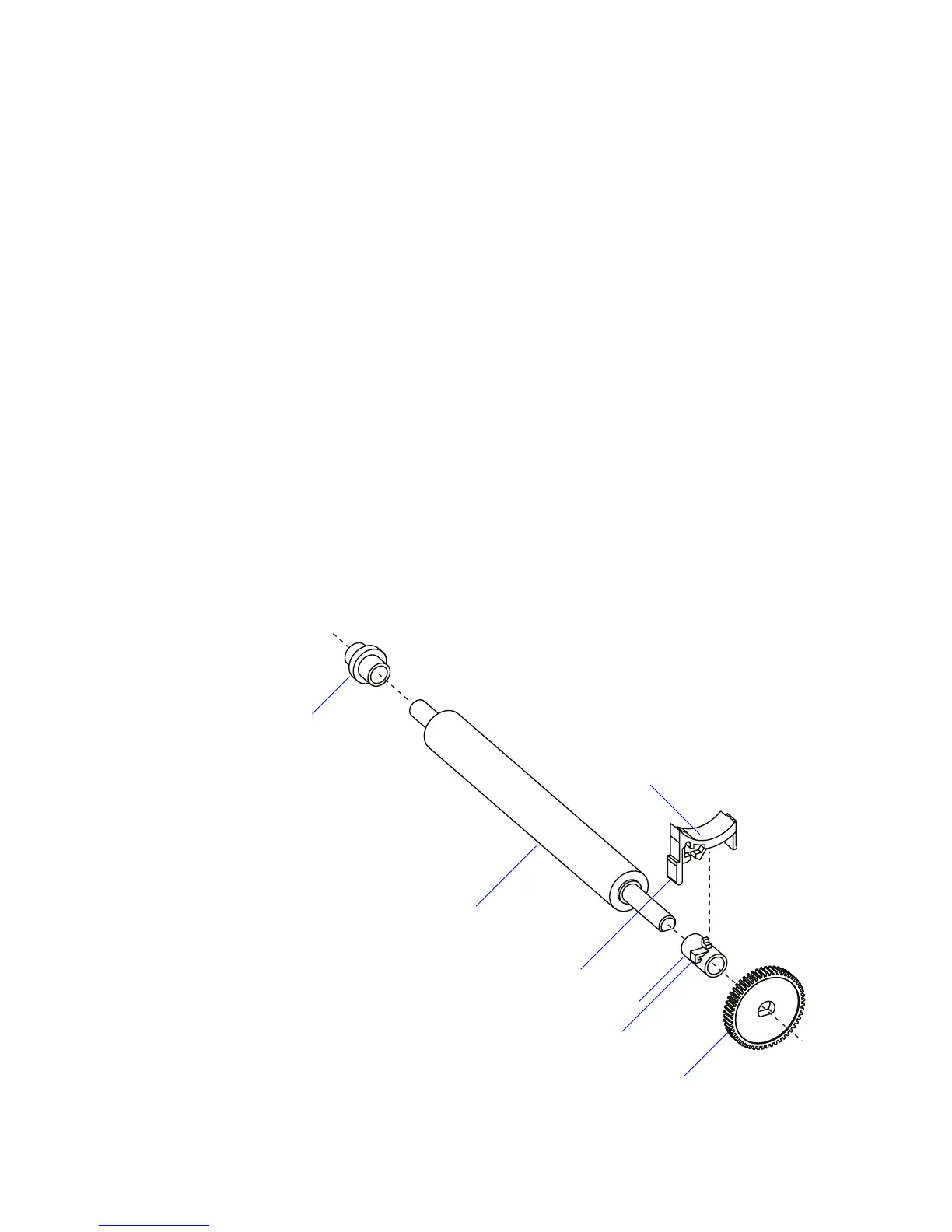

5.3 Platen Roller

Description

e platen roller feeds the media and provides counter-pressure for the

printhead. It is coated with silicon rubber and driven by the stepper motor

via a train of gears. e media feed is measured in dots, just like the print

width (1 dots = 0,125 mm/4.9 mils).

e platen roller is subject to wear and may need to be replaced.

Replacement

• From above, insert a flat-tipped screwdriver between the gear and the

platen cover and disengage the snap-lock of the platen cover. Pry up the

platen cover.

• Push the right-side bushing to the right to disengage it. en, using

a moderate amount of force, pry the bushing, gear, and platen roller

upwards.

• Lift out the platen roller and the left-side bushing.

• Replace with a new set of platen roller, bushings, and gear in reverse

order. Make sure that the D-plane of the left side bushing fits into the

D-shaped hole, and that the tab on the right-side bushing fits into the

corresponding slot in the base frame moulding before locking the assem

-

bly with the platen cover.

Plastic bushing

with brass insert

Right-side bushing

Tab

Platen roller

Platen cover

Snap-lock

Gear

Loading...

Loading...