Intermec EasyCoder PC4—Service Manual 39

Chapter 5—Base Frame

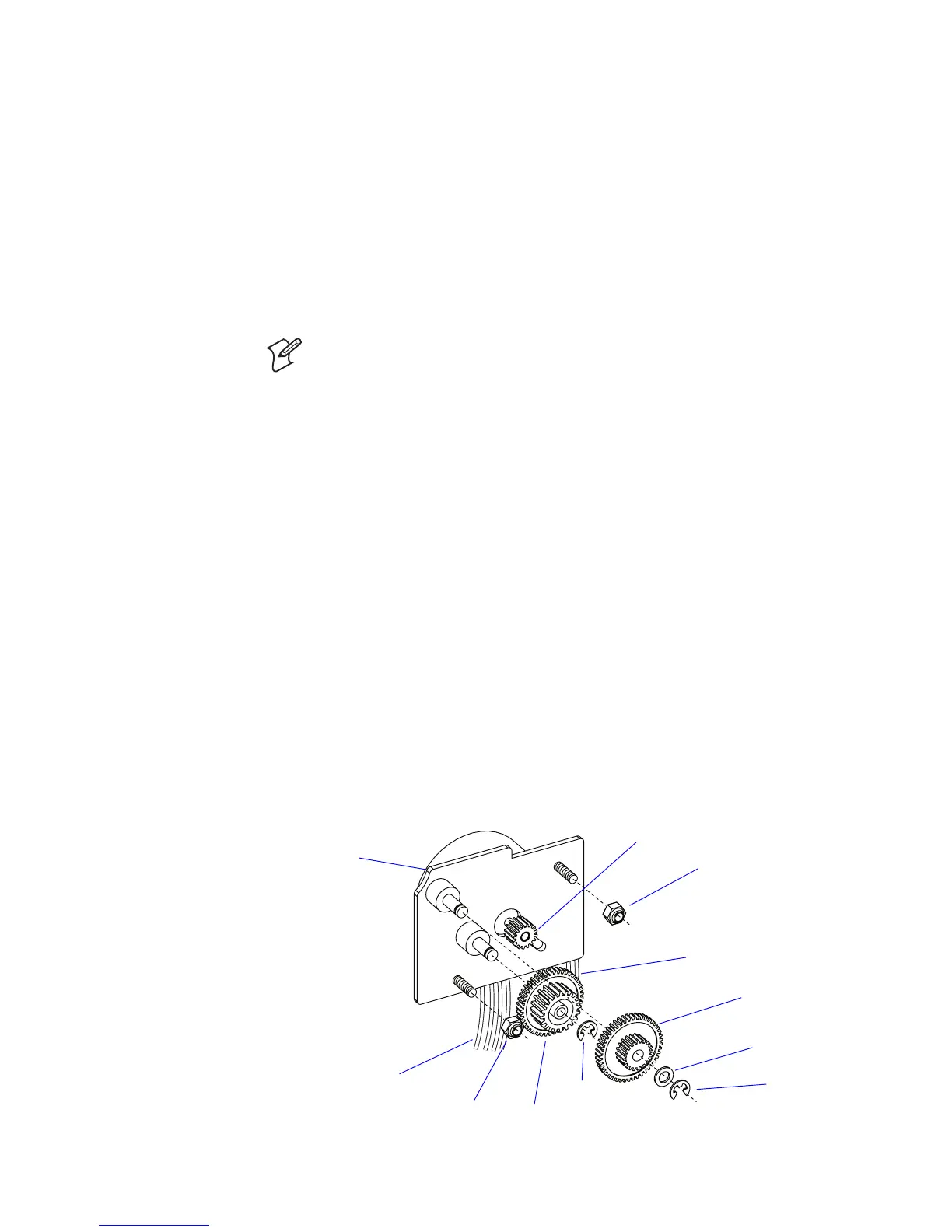

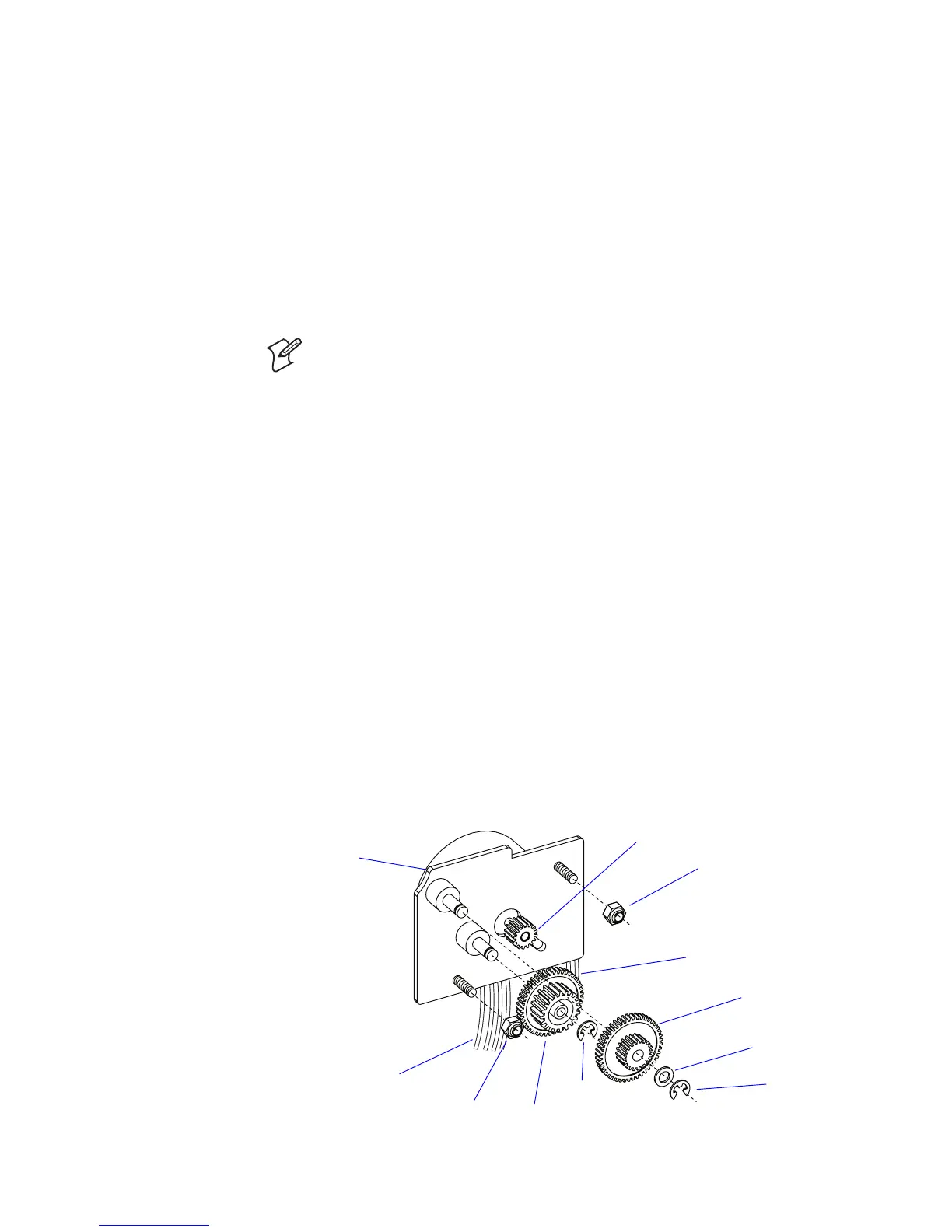

5.5 Motor assy

Description

e motor assembly consists of a stepper motor and a thermistor mounted

on a bracket, which is attached to the inner, right side of the base frame

moulding. e motor pulley and two shafts protrude through holes in the

base frame moulding. Outside the moulding two gears are fitted on the

shafts. e gears form a train from the motor pulley to the gear of the platen

roller. e platen roller gear engages the ribbon takeup gear, when the print

frame is closed.

Note: e stepper motor differs between the 202.3 dpi (8 dots/mm) and

the 300 dpi (11.81 dots/mm) models.

e termistor protects the stepper motor from overheating by stopping the

printing at approx. +80°C (+176°F). is is indicated by the LED flashing

red. When the temperature gets down to approx. +60°C (+140°F), which

usually takes 4.5 to 5 minutes, the LED switches back to green and any

interrupted print job is automatically resumed. Overtemperature is caused

by excessive load on the stepper motor (high print speed, continuous print

-

ing of too many labels, etc.) possibly in combination with a high ambient

temperature.

e stepper motor is connected to JP1 and the thermistor to JP2 on the

main board.

Replacement

e motor assy mechanism comes as a complete unit including stepper

motor, bracket, thermistor, gears, washer, E-rings, and nuts.

• Disconnect the cables from JP1 and JP2 on the main board.

• Remove the E-rings, washer, and gears

• Remove the two M3 self-locking nuts.

• Pull out the motor and bracket.

• Install a replacement unit in reverse order.

Washer

E-ring

E-ring

To JP1 on main board

To JP2 on main board

Motor, thermistor, and bracket

M3 nut

M3 nut

Pulley

Gear

Gear

Loading...

Loading...