Written not

allowed.

It only happen in write command, the reason maybe:

1. The data to write exceed the range of according parameter.

System

locked

When password protection take effect and user does not

unlock it, write/read the function parameter will return this

error.

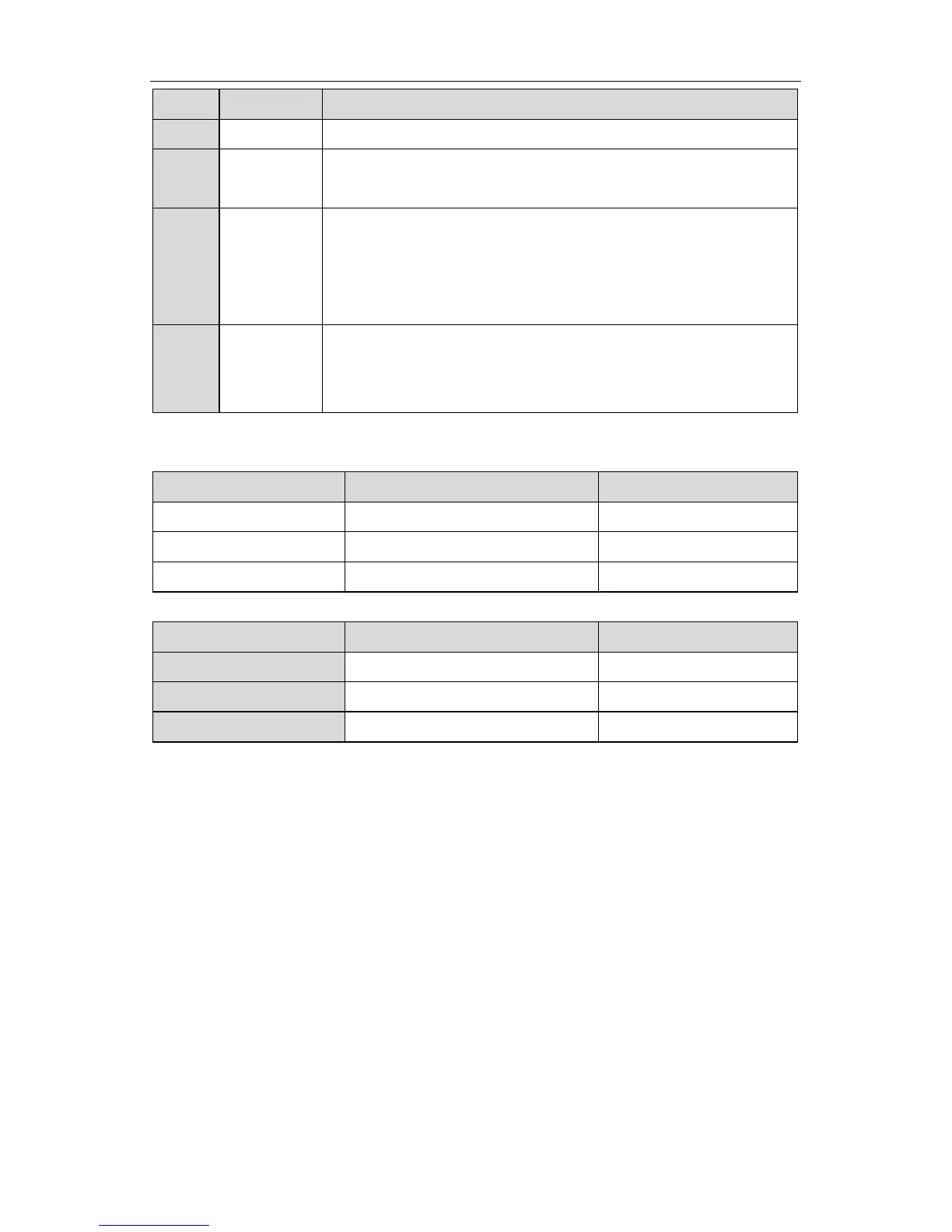

Protocol data unit format of writing single parameter:

Request format:

Protocol data unit Data length(bytes) Range

Command 1 0x06

Data Address 2 0~0xFFFF

Write Content 2 0~0xFFFF

Reply format (success):

Protocol data unit Data length(bytes) Range

Command 1 0x06

Data Address 2 0~0xFFFF

Write Content 2 0~0xFFFF

If the operation fails, the inverter will reply a message formed by failure command and

error code. The failure command is (Command+0x80). The error code indicates the

reason of the error; see table 1.

10.5 Note

10.5.1 Between frames, the span should not less than 3.5 bytes interval, otherwise, the

message will be discarded.

10.5.2 Be cautious to modify the parameters of PC group through communication,

otherwise may cause the communication interrupted.

10.5.3 In the same frame, if the span between two .near bytes more than 1.5 bytes

interval, the behind bytes will be assumed as the start of next message so that

communication will failure.