JAKA Zu MiniCab v1.1 35

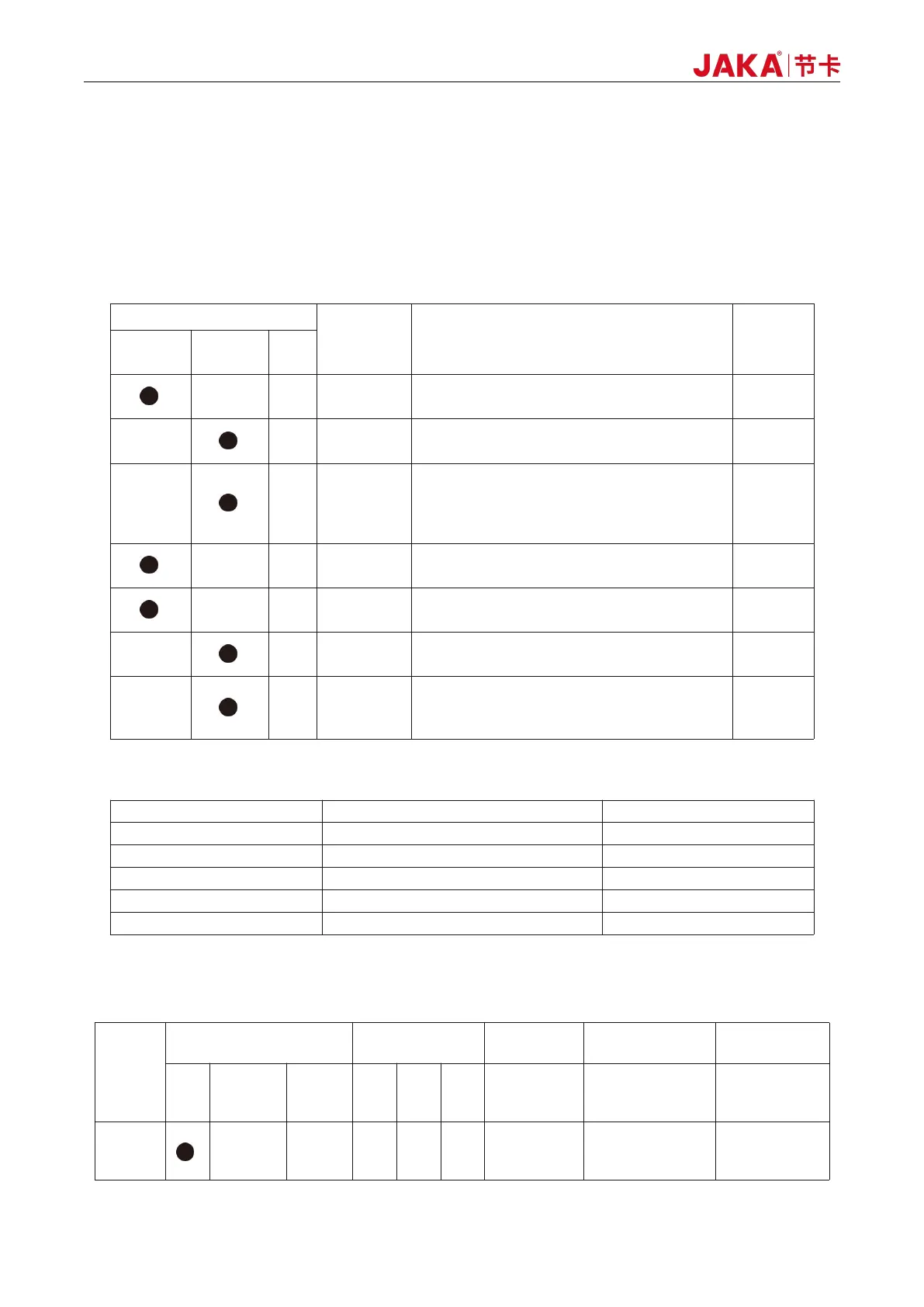

7.2 Maintenance Items and Cycles

In order to maintain high performance of the robot for a long time, maintenance inspection shall be carried

out. The responsible of maintenance shall develop a maintenance plan and carry out the maintenance work

practically. Please refer to the following table for maintenance items.

In addition, overhauling shall be required after 20,000 hours of operation or every four years (the shorter

period prevails). If the maintenance and adjustment method is unclear, please contact our Service Department.

Verify whether the storage position of the

program is deviated

Wipe off dirt, and clear dust, powder,

cutting pieces, etc.

All the bolts exposed outside the robot

shall be tightened, and the tool mounting

bolts shall also be applied for paint fixing (see

the specified tightening torque table)

Confirmation of abnormal heating and

abnormal sounds

Verify that the robotic arm or tool does

not drop, when the servo power is ON/OFF

Confirmation of abnormal vibration,

abnormal sound and oil leakage

Apply force to the front, back, left, right,

up and down of the tool to make sure your

hand doesn't feel shaking

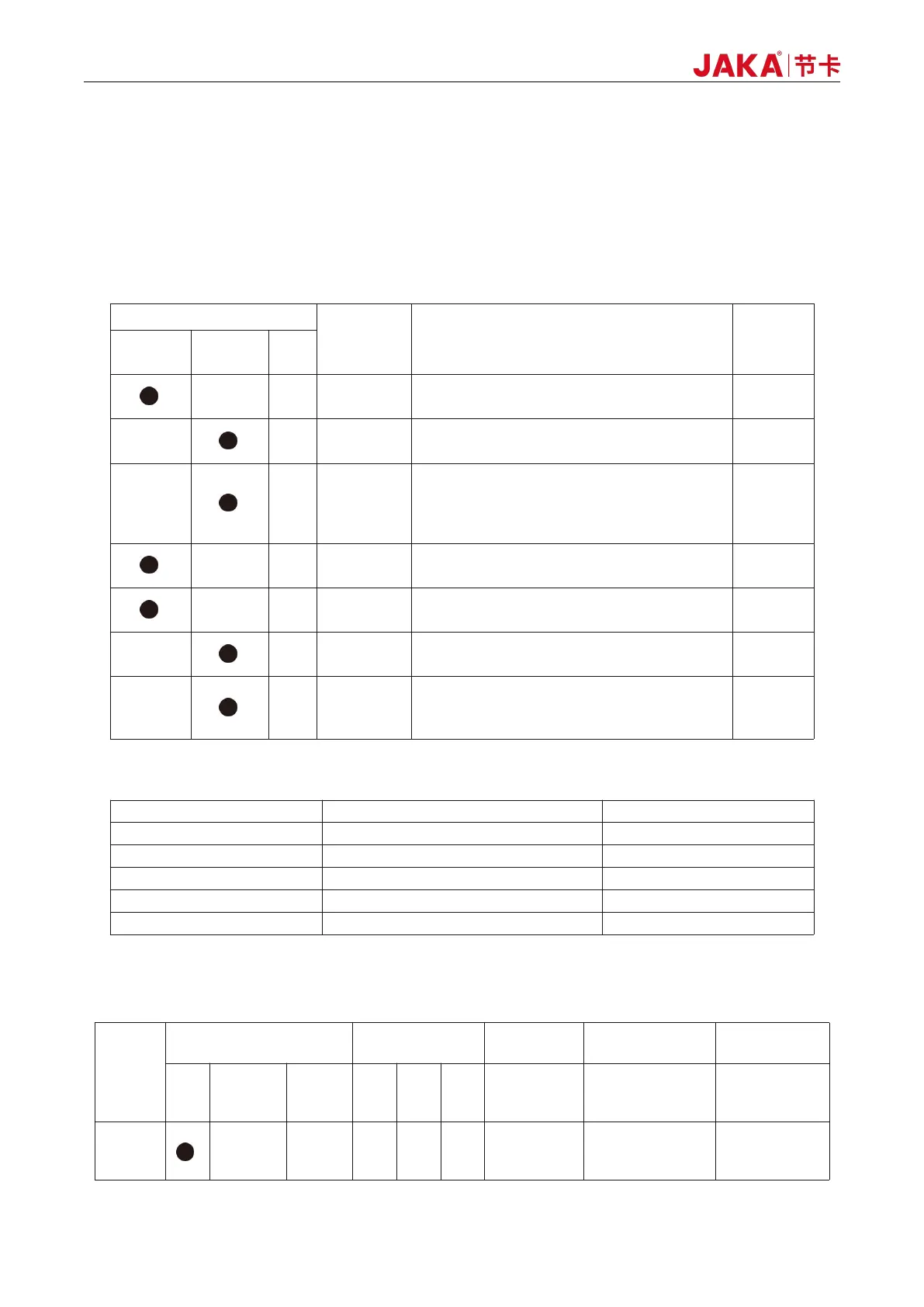

Table of specified fastening torque for bolts

The fastening torque will vary according to the types of base material or bolt. If it is not shown in the text or

figure, please follow the tightening torque in this table.

Spatter, dust and

other impurities

attached

Visual

verification

and cleaning

Loading...

Loading...