135

14. Drive Face/Clutch/Driven Wheel/Kickstart Mechanism

Preparing documents -------------------14.1 Clutch/driven wheel ---------14.5

Failure diagnosis --------14.2 Breakdown of clutch and driven wheel -----14.6

Left crankcase cover ----------------14.3 Installation --------------------14.7

Drive face ----------------------------14.4 Kickstart mechanism------------14.8

14.1 Preparing documents

During operation, the surface of the triangle belt cannot be stained with any grease that must be

removed. It helps avoid slipping between the triangle belt and the belt pulley as much as possible.

Function: Drive face, clutch and driven wheel constitute stepless transmission. The triangle belt transfers torque

between the drive face and the driven wheel.

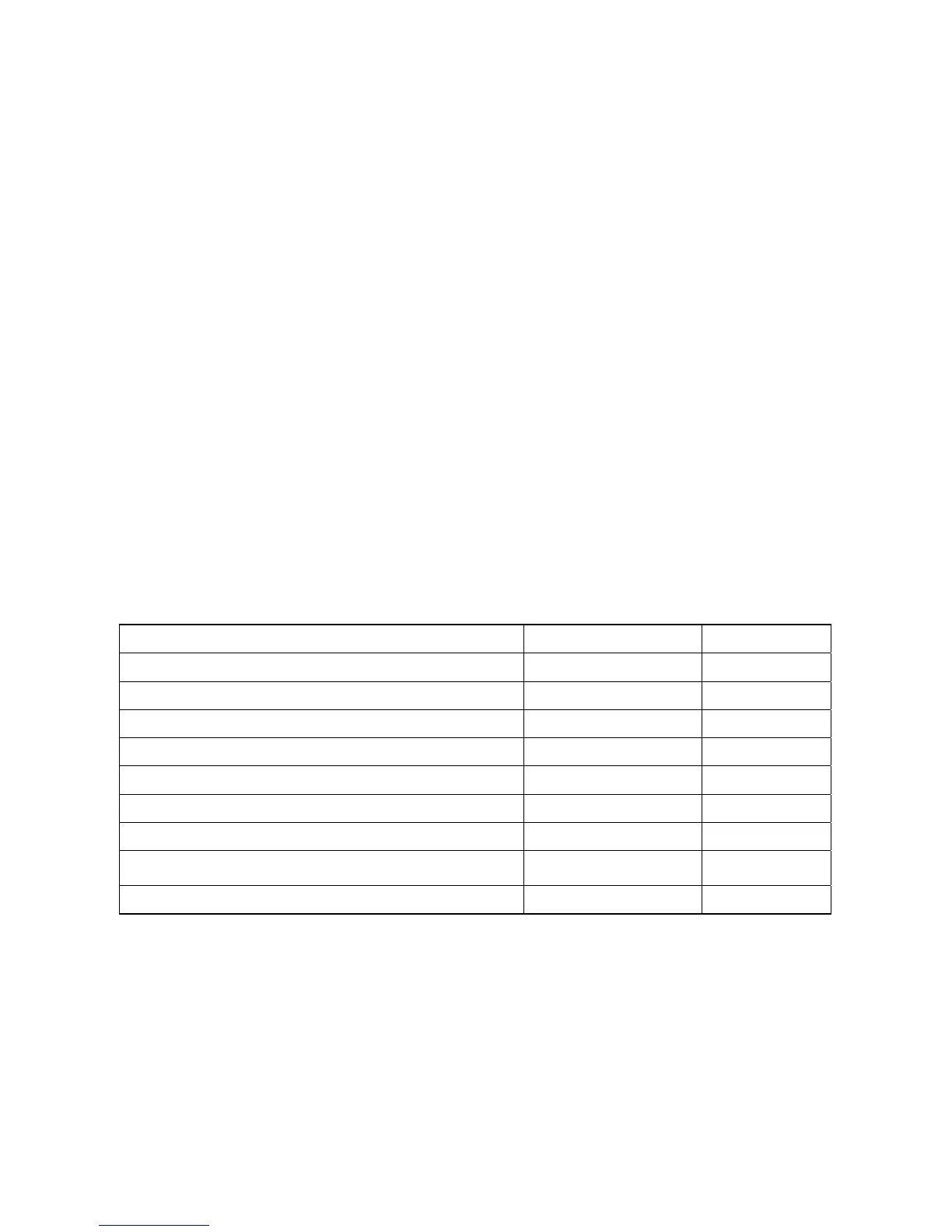

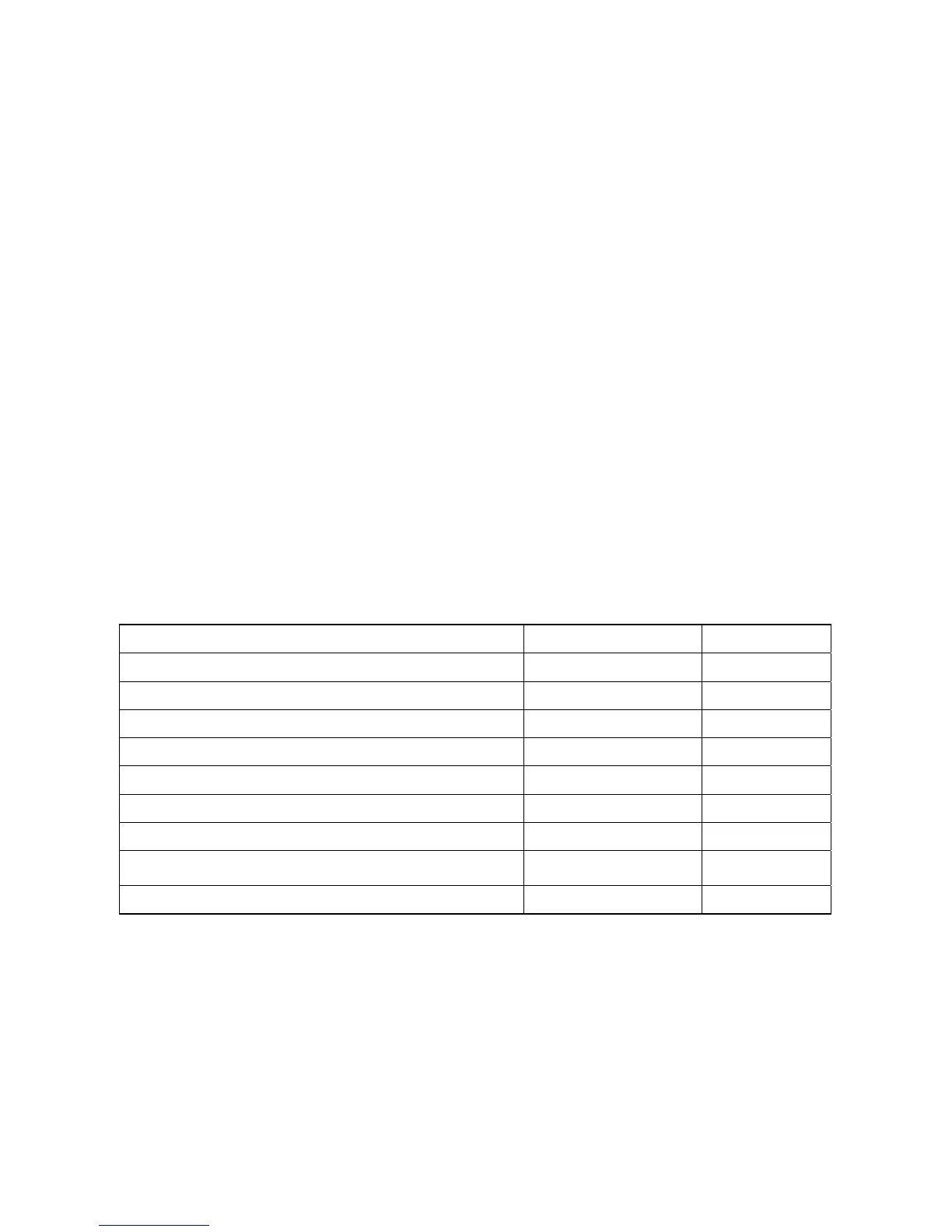

Preparing Principles Unit: mm

Item Standard Limit for use

Inner diameter of right half-driven wheel 20-20.05 20.05

Outer diameter of the sliding sleeve 19.94-19.98 19.94

Width of the triangle belt 18 18

Thickness of the clutch facing 3.5 3.5

Inner diameter of the clutch sleeve 107-107.2 107.2

Free length of the clutch spring 93-97 93

Outer diameter of the bushing on the right half driven wheel 33.95-33.975 33.95

Outer diameter of the sliding sleeve on the left half driven

wheel

34.025-34.064 34.064

Outer diameter of the ball 15.8-16.2 15.8

14.2 Failure diagnosis

No run after engine startup Insufficient horsepower Vibration during driving

Abrasive triangle belt Abrasive triangle belt Ruptured clutch facing spring

Damaged driven wheel Distorted clutch spring

Broken or damaged clutch facing Abrasive ball

Loading...

Loading...