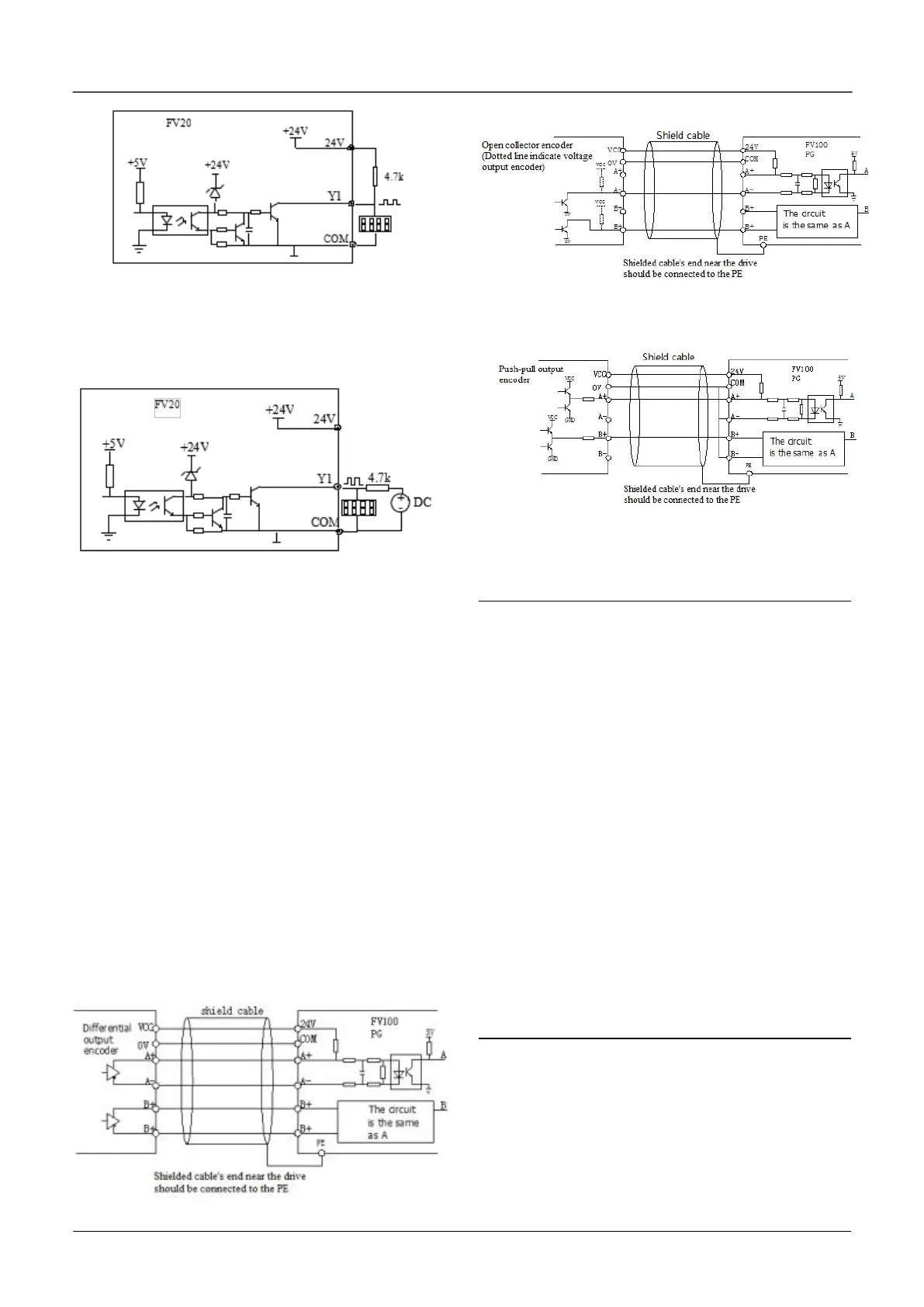

Fig 4-15 Wiring method 1 of output terminal Y2

4. When Y1 is used as a digital pulse frequency

output, it can also use the external power supply.

The wiring is shown in Fig.4-16

Fig.4-16 Wiring method 2 of output terminal Y2

Wiring of relay output terminals R1a, R1b and R1c

If the drive drives an inductive load (such as

electromagnetic relays and contactor), then a surge

suppressing circuit should be added, such as RC

snubbing circuit (Notice that the leakage current

must be smaller than the holding current of the

controlled relay or contactor) and varistor or a

free-wheeling diode (Used in the DC

electric-magnetic circuit and pay attention to the

polarity when installing). Snubbing components

should be as close to the coils of relay or contactor

as possible.

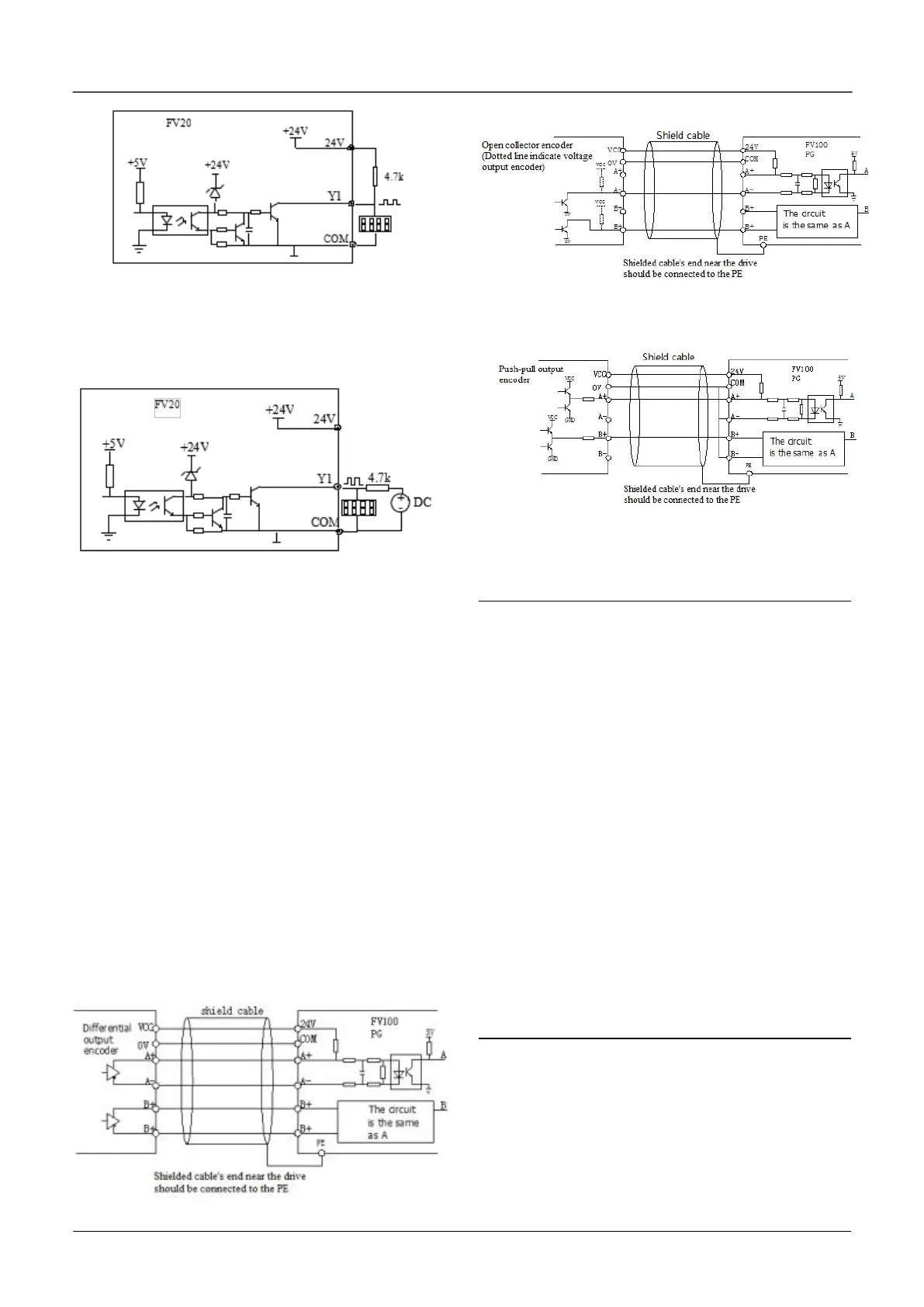

5. Attentions for encoder (PG) wiring

Connection method of PG signal must be

corresponding with PG model. Differential output,

open collector output and push-pull output encoder

wirings are shown in Fig.4-17, 4-18 and 4-19.

Fig 4-17 Wiring of differential output encoder

Fig.4-18 Wiring of open collector output encoder

Fig.4-19 Wiring of push-pull output encoder

Note

1. Don’t short circuit terminals 24V and COM,

otherwise the control board may be damaged.

2. Please use multi-core shielded cable or

multi-stranded cable (above 1mm²) to connect the

control terminals.3. When using a shielded cable,

the shielded layer’s end that is nearer to the drive

should be connected to PE.

4. The control cables should be as far away(at least

20cm) from the main circuits and high voltage

cables as possible (including power supply cables,

motor cables, relay cables and contactor cables and

so on). The cables should be vertical to each other

to reduce the disturbance to minimum.

5. The resistors R in Fig. 4-13 and Fig.4-14 should

be removed for 24V input relays, and the resistance

of R should be selected according the parameters

of relay for non-24V relay.

6. Digital output terminal can not stand the voltage

higher than 30V

Loading...

Loading...