5-1

COMPONENT TESTING

Before testing any of the components, perform

the following checks:

• The most common cause for control failure is

corrosion on connectors. Therefore, discon-

necting and reconnecting wires will be nec-

essary throughout test procedures.

• All tests/checks should be made with a VOM

or DVM having a sensitivity of 20,000 ohms-

per-volt DC, or greater.

• Check all connections before replacing com-

ponents, looking for broken or loose wires,

failed terminals, or wires not pressed into

connectors far enough.

• Resistance checks must be made with power

cord unplugged from outlet, and with wiring

harness or connectors disconnected.

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

INFINITE (SMART) SWITCH

L1a / L1 / N

D / S (DUAL)

S (SINGLE)

Refer to page 4-4 for the procedure for servic-

ing an infinite switch.

1. Unplug range or disconnect power.

2. Disconnect the wire connectors from the

infinite switch.

3. Set the ohmmeter to the R x 100 scale.

4. Touch the ohmmeter test leads to the

infinite switch connector pins as follows:

Switch Off: L1a to 2 = open circuit (∞ )

Switch On: L1a to 2 = closed circuit (0 Ω)

Switch Off: L1a to 1 = open circuit (∞ )

Switch On: L1a to 1 = closed circuit (0 Ω)

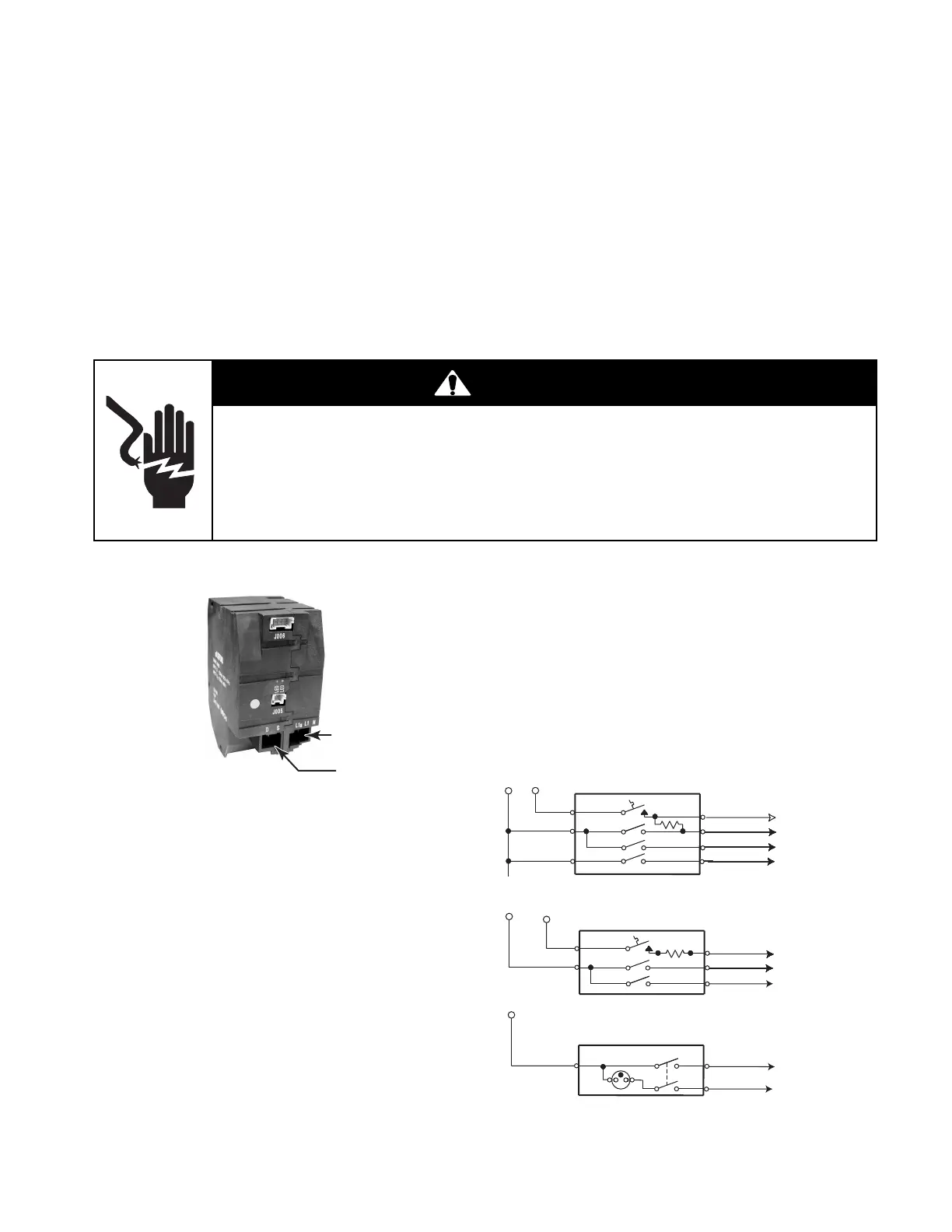

DUAL & SINGLE INFINITE &

WARMING DRAWER SWITCHES

MODELS: KESV808, KESV908, &

KESI901

NOTE: These switches are not included in this

Job Aid, but are standard switches found on

the model ranges listed above. A wiring dia-

gram for each switch is shown below.

TO LIMITER 2A

TO LIMITER 2A

TO NEUTRAL

TO L1 (INNER ELEMENT)

TO L1 (ELEMENT)

TO 2B ON ELEMENT

TO L2 (OUTER ELEMENT)

TO INDICATOR LIGHT

TO INDICATOR LIGHT

H1

H2

LR

Y/W

BU

Y

L1

L2

P

R

L1

L1

L2

L2

BK

4

2

LF

OR/W

OR/BK

OR

S2

P1

S1

P2

4A

BK

BK

L1

BK

R

BU

2

GY

W

3

1

WARM

DUAL INFINITE SWITCH

SINGLE INFINITE SWITCH

WARMING DRAWER SWITCH

Loading...

Loading...