64

6 Maintenance and cleaning

6.9 Maintenance PowerSheet

®

(option)

6.9.1 Maintenance check of the PowerSheet

®

This work may only be carried out by technically trained personnel with experience in repairing and maintaining

electromechanical systems.

Check at least once a year for the following safety aspects:

Regularly check the motor mounting bolts for a minimum tightening torque of 8 Nm

Regularly check all mountings for proper securing of all parts.

Check all moving parts for wear.

Check the rear strap and the roof sheet for wear.

Checktheconditionofthelockingplates/tensionprole.

Check the spring tension of the strapreturn mechanism.

Check the spring tension of the springs at the pivot points at the front.

Check legibility of safety stickers.

Regularlycheckallelectricalconnectionsforcorrosion.Ifaconnectioniscorroded:thoroughlycleanthe

connection(ensurethatthesystem'spowersupplyisswitchedoff)andprotectitwith,forexample,Vaseline.

Electricalconnectionscanbefoundat:electricmotor,motorcontrolunit,remotecontrolreceiver,junctionboxes,

batteries and fuses.

6.9.1 Repairs/replacement of parts

During the warranty period, repairs may only be performed under the direction of the manufacturer.

When replacing parts, only original replacement parts should be used.

6.10 Maintenance hydraulic system

Tips for recognition of dirty oil and replacing the oil lter yourself can be found in the

Knapen Trailers driver tips no 4 "The hydraulic system".

www.knapen-trailers.eu/downloads/tips-for-drivers

The following check is important for the life of the oor system:

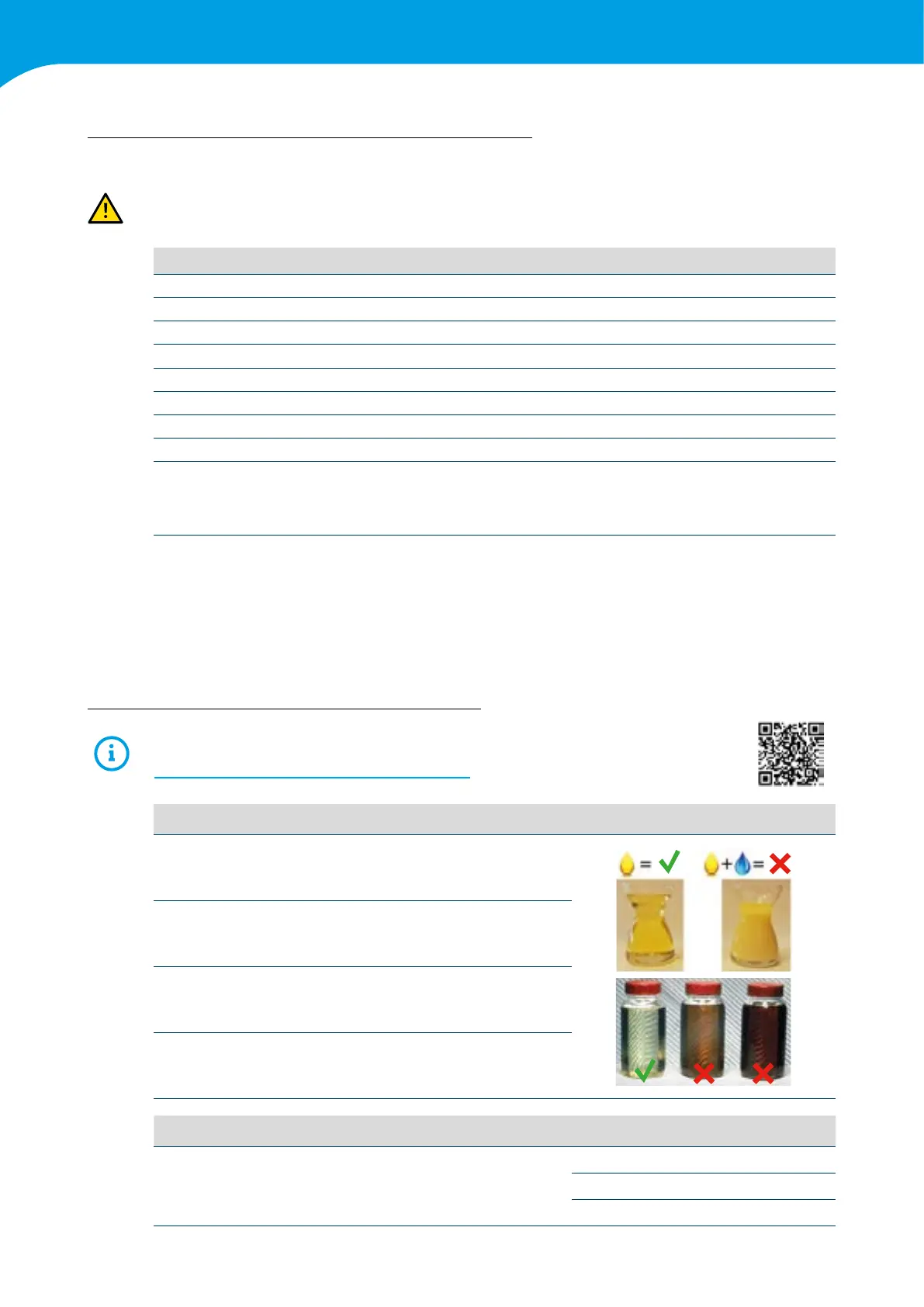

Check the quality of the oil; it must be changed regularly

(check every ½ year)

Replacelterelementeveryyear

Change oil every 2 years, or more frequently if necessary

Check the amount of oil in the tank. There should constantly be

min. 150 litres of oil present to suppress heat generation. Use the

prescribed oil

Hydraulic oil Type

Temperature

Prescribed quality

ISO22 -25°C>0°C

ISO32 -15°C>30°C

ISO46 15 ° C > 40 ° C

Loading...

Loading...