65

User Manual EN | v201906

7 Troubleshooting

7.1 Troubleshooting moving oor

Iftheoorsystemdoesnotfunctionproperly,ordoesnotfunctionatall,despitethemeticulousfollow-upofthe

operatinginstructions,checkthefollowingpoints:

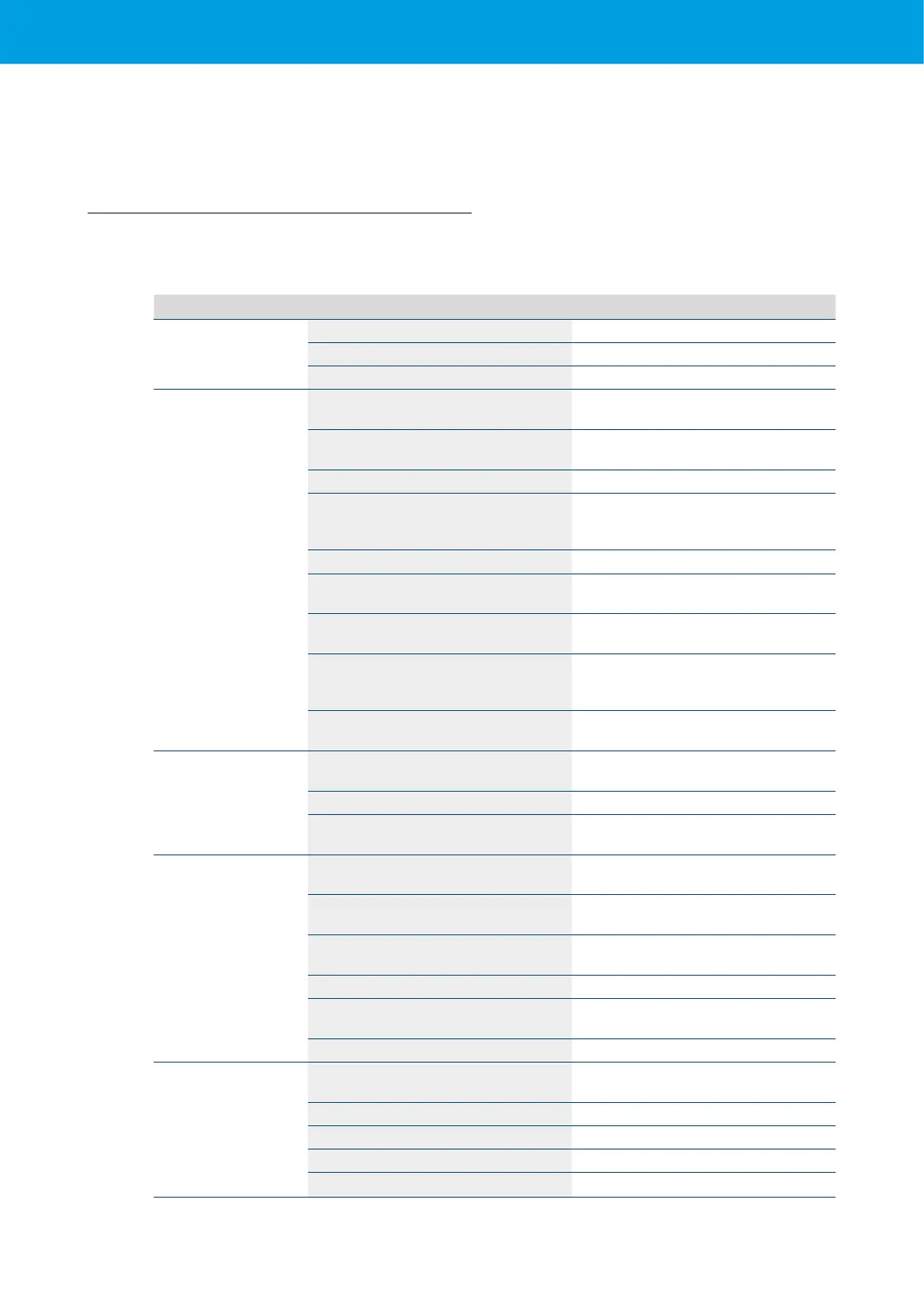

System malfunction Cause Solution

System is not working,

nooilow

control valve

PTO not switched on Switch on PTO

Block quick couplings Check quick couplings/mount correctly

Pressure-reliefvalvetruckbroken Replacepressure-reliefvalve

System is not working,

oilowat

control valve

Lighting not switched on, no power on the

system

Switch on the lighting

Temperature protection switched on,

oil temperature is higher than 70 ° C

Cool oil to 60 ° C

Emergency switch operated Deactivate the emergency switch

Magnetic valve GS02 on/off Break in coil/

wiring

Temporarily activate the emergency

control GS02 and/or repair the power

circuit

Dirtypressure-reliefvalve Clean with compressed air/replace

Controllever(B-control)isinthecentre

position

Move the control lever towards loading or

unloading

Controlvalve(E-control)isincentre

position Flow < 60 l/m [16 gpm]

IncreasethespeedofthepumpInstall

otherpumpAdjustthethrottle

Controllever(B-control)isinthecentre

position

Hoses connected incorrectly

Firstcheckthelter,thenconnectpressure

and return correctly/turn

Control lever moves heavily due to molten

seals

Replace control lever seals

Start immediately

after switching on PTO

CF3 or CF7 movement switch blocked in

the “on” position

Unblock

Emergency control GS02 activated Turn switch out, yellow clip in between

Pressure and return line exchanged

Firstcheckthelter,thenconnectthe

pressure and return pipe correctly

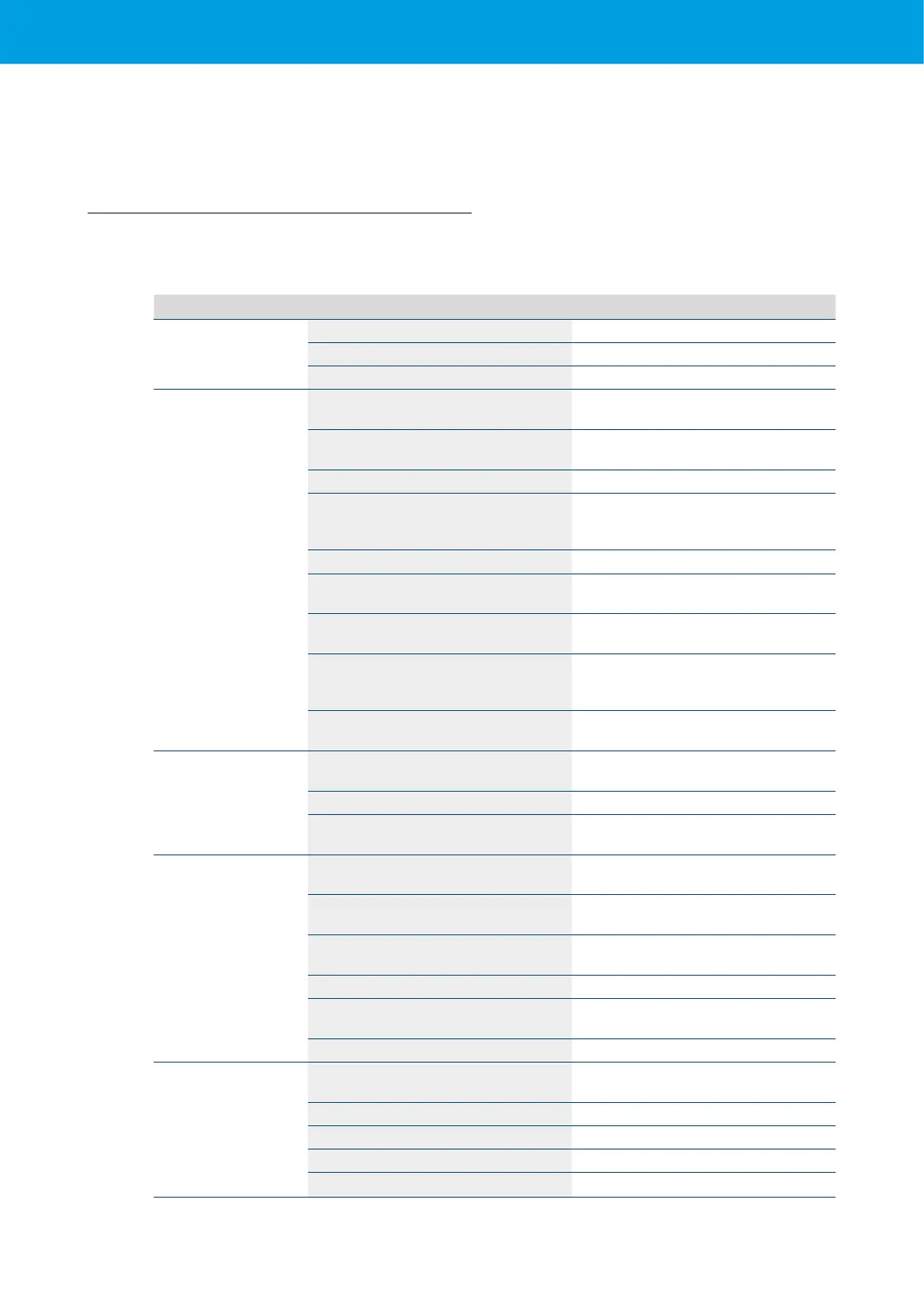

Individual

movement is

difcultand/orincorrect

withfullsemi-trailer

Dual pressure tipping valve

Put the tipping valve in the correct

position, high pressure

Pressure relief valve truck maximum

pressure too low

Measuring/adjustingthemaximum

pressure of the truck

Pressure relief valve return oil has

restriction

Measure pressure at measuring point M2,

remove restriction

Capacityisinsufcientduetooverloading Partially unload with crane

Capacityisinsufcientduetopolution

betweentheproles

Cleantheoor

Capacityisinsufcientduetofrost Defrost the load

Individualmovement

unloading incorrectly

with full and empty

semi-trailer

Valve in cylinder head 1 or 2 dirty and

prevents proper closure

Remove polution

Broken valve spring in cylinder head 1 or 2 Replace spring

Valve seat cylinder head 1 or 2 loose Replace/secure the seat*

Plug in the common rail is loose Tighten plug/replace common rail

Common rail mounted in wrong way Mount the common rail correctly

Loading...

Loading...