56

LAUNCH PAD V

User's Manual

(2) Checking for the output signal of knock sensor

Unplug the wire connector of knock sensor, check voltage between

knock sensor connector terminal and ground wire of knock, it should

be output pulse voltage; otherwise, the knock sensor shall be

replaced.

Coolant temperature sensor testing

(1) Resistance test for coolant temperature sensor

On vehicle testing:

Switch ignition “OFF” and unplug the wire connector of coolant

temperature sensor, then use the “Resistance measurement” to test

the Resistance between two terminals of sensor. The relationship

between the resistance and the temperature is in inversely proportion

(negative temperature coeffi cient), which shall be less than 1kΩ during

warming up.

Independent testing:

Unplug the wire connector of coolant temperature sensor, then remove

the sensor from the engine; place the sensor into a breaker with water

and heat the water, then use the “Resistance measurement” to test

the Resistance between two terminals of coolant temperature sensor

at different water temperature. Compared the measured value with the

standard value, if the Resistance is not compliant with the standard,

then the coolant temperature sensor shall be replaced.

(2) Output signal voltage testing for coolant temperature sensor

After installing the coolant temperature sensor, plug the wire connector

of sensor, and then switch ignition ON, test the output signal voltage

between the two terminals of wire connector. The tested voltage shall

be in inverse proportional with the coolant temperature. When the

harness of coolant temperature sensor is disconnected, the voltage

shall be about 5V if the ignition switch is ON.

7.2 Battery Tester (V1.0, Optional)

7.2.1 Product Summary

The tablet provides an optional function of automotive battery

test, which adopts the latest state-of-the-art conductance testing

technology in the world and can test vehicle’s battery status. Two

testing environments (Inside the Vehicle and Outside the Vehicle)

are available and applicable to battery test. In addition to battery test,

charging system and actuation system test can be done while Inside

the Vehicle is selected.

It supports various battery standards and specifications, including

CCA, DIN, IEC, EN, JIS, SAE and GB etc. It is specifi cally designed

to help car owner, repair workshop, battery factory use battery test

instrument properly and determine whether the battery is normal or

not.

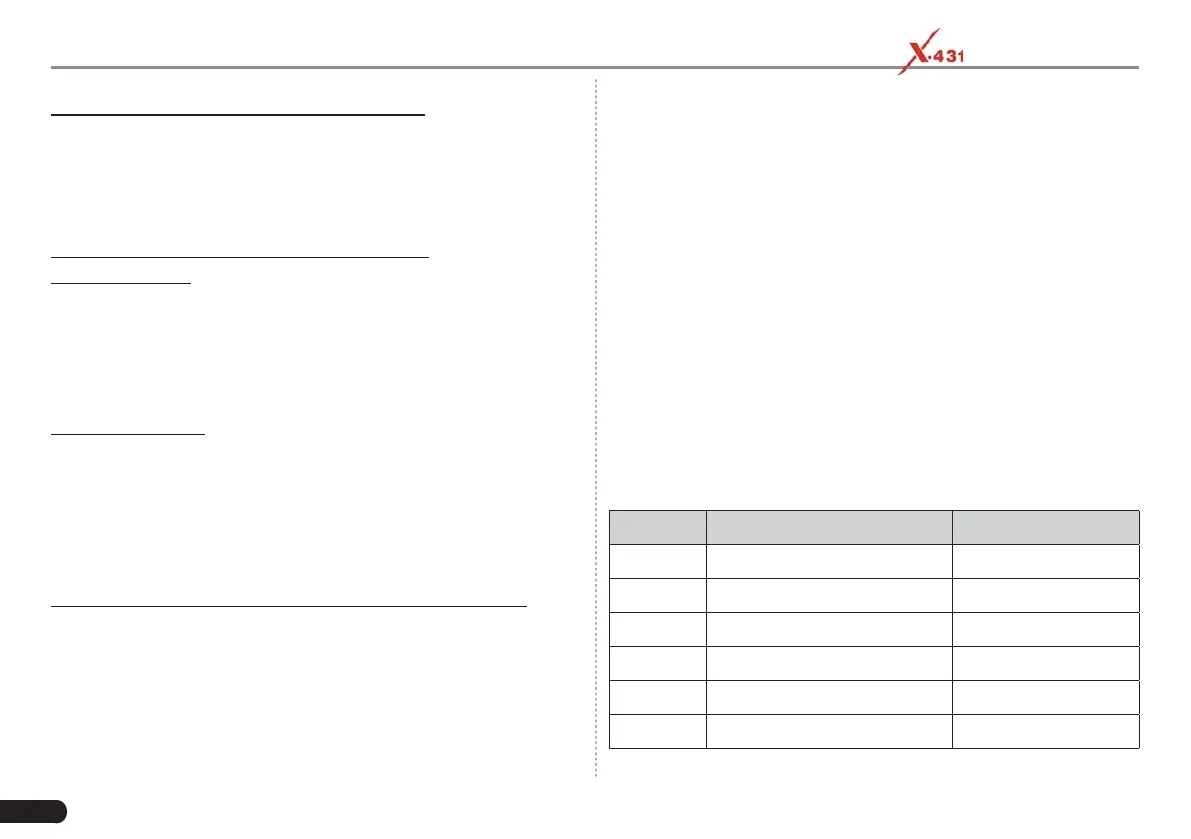

Battery test aims to check starting plumbic acid storage batteries for

vehicles, ship, boats and aviations, etc. It can test all kinds of batteries

complying with CCA, DIN, JIS, EN, GB and SA standards. For detailed

test standards, see the following table.

Standards Standard (Full name) Test capacity range

CCA Battery Council International 100

~

1700

DIN Deutsche Industry Normen 100

~

1200

JIS Japanese Industry Standard 26A17

~

245H52

EN Europe Norm 100

~

1700

IEC National Electrical Commission 100

~

1200

GB Chinese National Standard 100

~

1200

Loading...

Loading...