Electrical installation

Standard devices in the power range 55 ... 75 kW

Motor connection

5

195

EDKVS9332X DE/EN/FR 8.0

Characteristics of the connection for motor temperature monitoring:

Terminals T1, T2

Connection

l PTC thermistor

– PTC thermistor with defined tripping temperature (acc. to DIN 44081 and

DIN 44082)

l Thermal contact (NC contact)

– Thermostat as NC contact

Tripping point l Fixed (depending on the PTC/thermal contact)

l PTC: RJ

> 1600 W

l Configurable as warning or error (TRIP)

Notes l Monitoring is not active in the Lenze setting.

l If you do not use a Lenze motor, we recommend the use of a PTC thermistor up

to 150°C.

T1

T2

PE

U

VW

2

3

4

M4 x 12: 2.5 Nm (22.1 lb-in)

M5 x 12: 3 Nm (26.5 lb-in)

U, V, W,

PE

M10

30 Nm

264 lb-in

1

0

T1

T2

2.5 Nm

22.1 lb-in

5

}

+

PE

9300std032

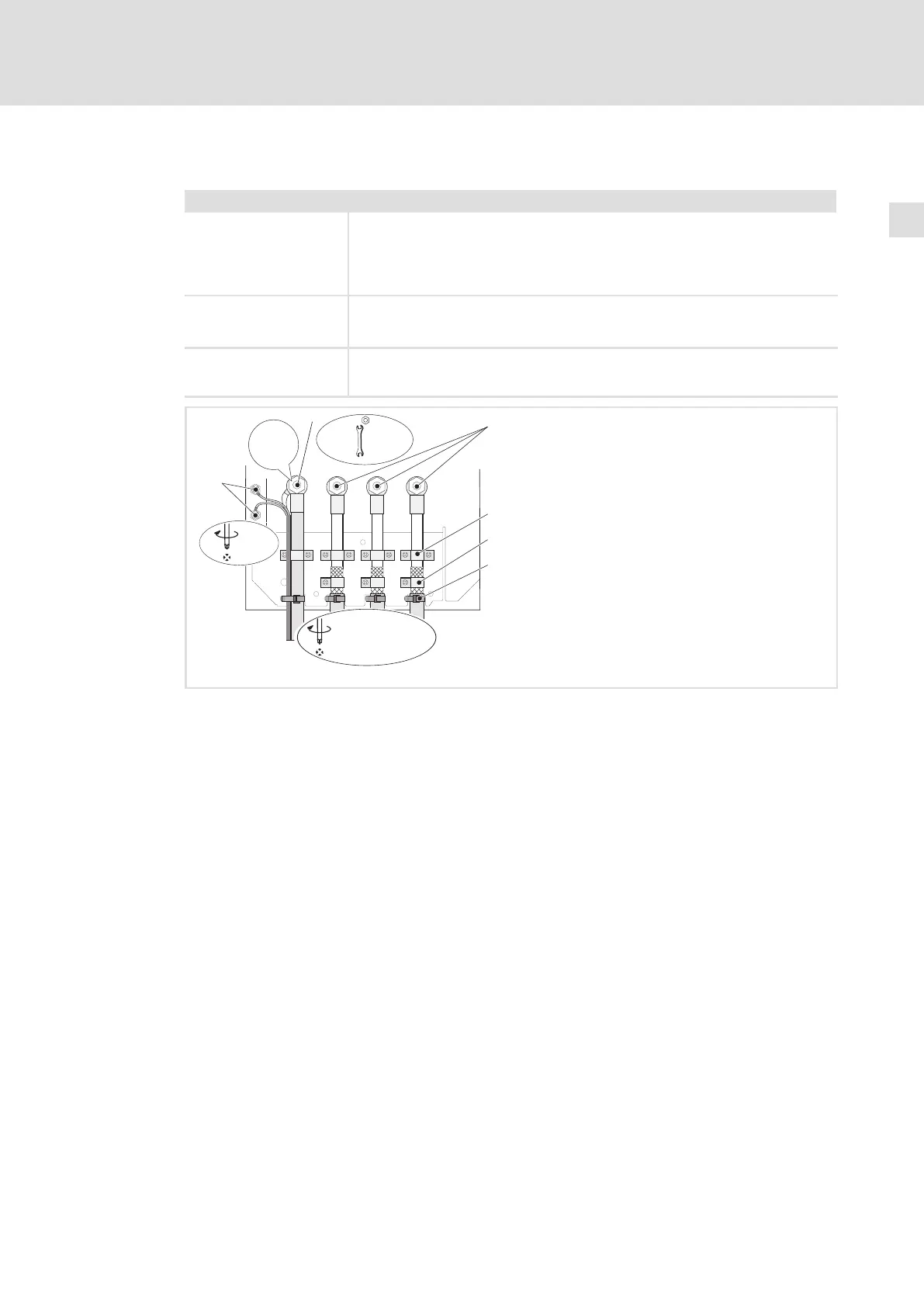

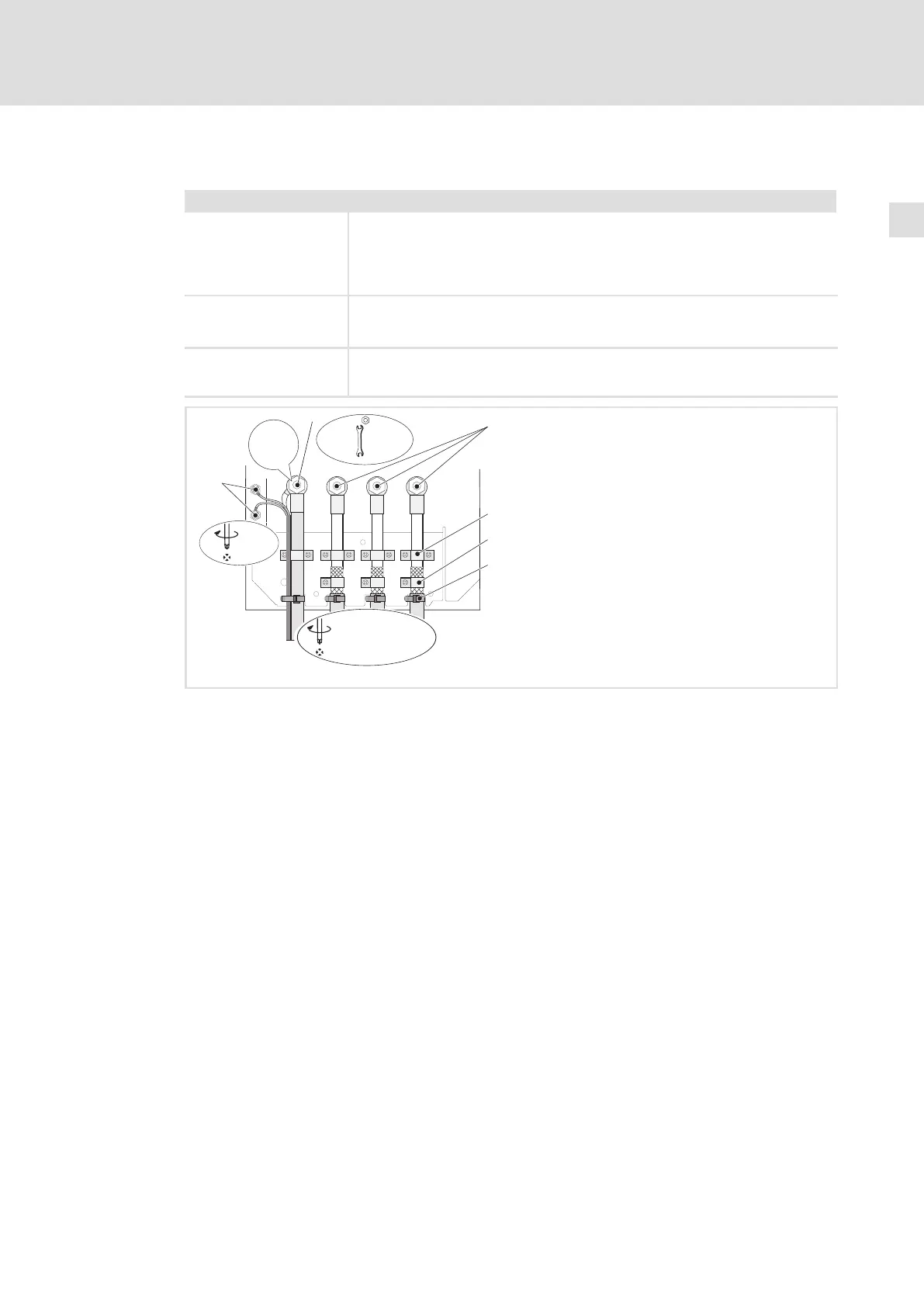

Fig. 5−22 Motor connection with PTC thermistor or thermal contact (NC contact)

PE stud

PE cable connection with ring cable lug

U, V, W

Motor cable connection

Check the correct polarity. Observe maximum length of the motor cable.

Max. connectable cable cross−section: 240 mm

2

with ring cable lug

Cable clamps for strain relief of motor cable

Fasten cable clamps with M4 × 12 mm screws

Shield clamps

Place shields of motor cable with large surface on the shield sheet and fasten with shield

clamps and M5 × 12 mm screws

Cable ties for additional strain relief of motor cable

T1, T2 for motor temperature monitoring

Cable connection for PTC thermistors or thermal contacts (NC contacts)

Place shield with large surface on PE stud

Loading...

Loading...