6

CHAPTER 1 - INSTALLATION

1.1 Inspection

l Inspect the inverter for any damage that may have occurred during shipping.

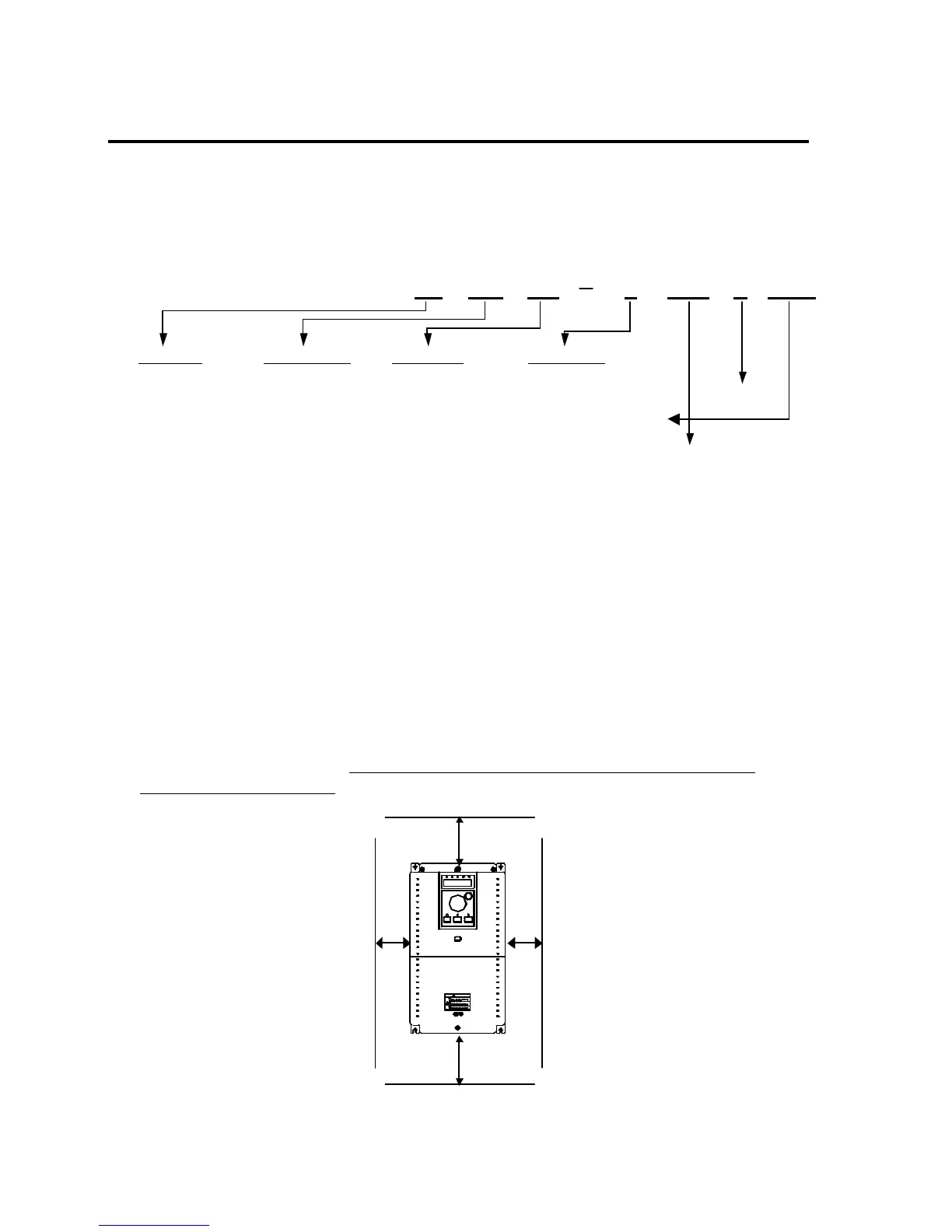

l Check the nameplate on the inverter. Verify the inverter unit is the correct one for the application. The numbering

system for the inverter is as shown below.

LG Inverter Motor Capacity Series Name Input Voltage

008: 1 HP 075: 10 HP 2: 200 ~ 230V (±10%) (50/60Hz)

015: 2 HP 110: 15 HP 4: 380 ~ 460V (±10%) (50/60Hz) UL Listed

022: 3 HP 150: 20 HP 4: 380 ~ 480V(±10%) (50/60Hz)

037: 5 HP 185: 25 HP

055: 7.5 HP 220: 30 HP N: Without Keypad

O/E: UL Open/Enclosed Type 1

DB: Built-in DB Unit

1.2 Environmental Conditions

l Verify ambient condition for the mounting location.

- Ambient temperature should not be below 14ºF (-10ºC) or exceed 104ºF (40ºC).

- Relative humidity should be less than 90% (non-condensing).

- Altitude should be below 3,300ft (1,000m).

l Do not mount the inverter in direct sunlight and isolate it from excessive vibration.

l If the inverter is going to be installed in an environment with high probability of penetration of dust, it must be

located inside watertight electrical boxes, in order to get the suitable IP degree.

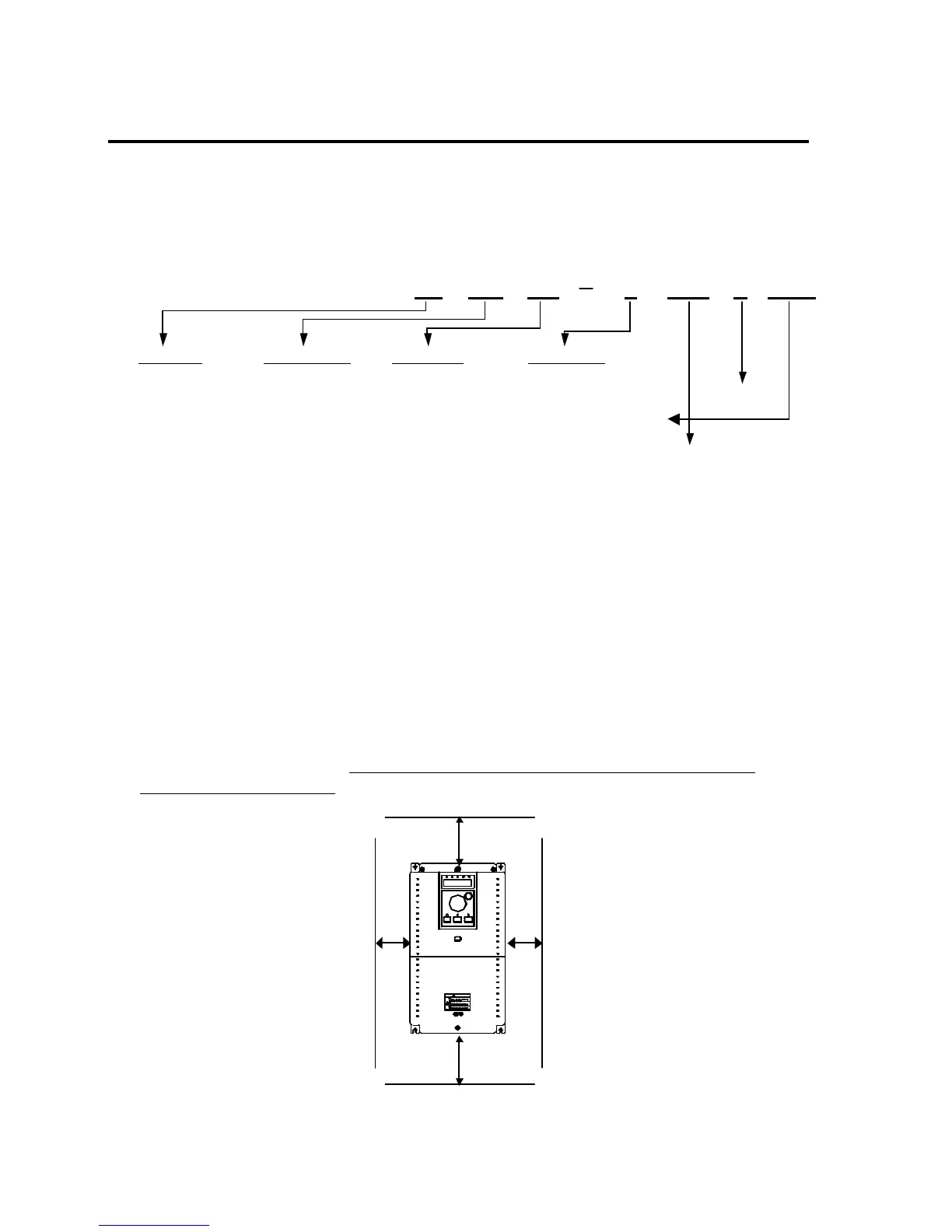

1.3 Mounting

l The inverter must be mounted vertically with sufficient horizontal and vertical space between adjacent equipment

(A= Over 100mm, B= Over 50mm). However, A= Over 500mm and B= 200mm should be obtained for

inverters with 40Hp and above.

iS5

VARIABLE FREQUENCY DRIVE

Risk of Injury or Electric Shock

Risk of Electric Shock

Risk of Electric Shock

WARNING

EXT

RUN

ESC

SHIFT

FU2FU1DRV

ENT

PROG

RESET

STOP

LE-200

I/O

B

Loading...

Loading...