Page 3-4

MPS Motor Protection System Rev. 6-F-022117

System Wiring

3.2.1.4.1 DC OPERATION

Supply voltage for dc-input operation can be obtained

from the 24-Vdc source (terminals 41 and 42), or it can be

obtained from an external 12- to 120-Vdc supply.

The internal source is current limited at 100 mA and is

referenced to the analog output (terminal 40) and the I/O

Supply (terminal 56). Connect the “−” terminal of the dc

source to COM and connect field inputs between “+” and

the digital-input terminals.

3.2.1.4.2 AC OPERATION

Inputs operate over a 12- to 120-Vac range. Connect

the ac neutral to COM and connect field inputs between

line and the digital inputs.

3.2.1.4.3 COMBINED AC AND DC OPERATION

If both ac and dc inputs are used, connect both the ac-

supply common and dc-supply “−” to COM.

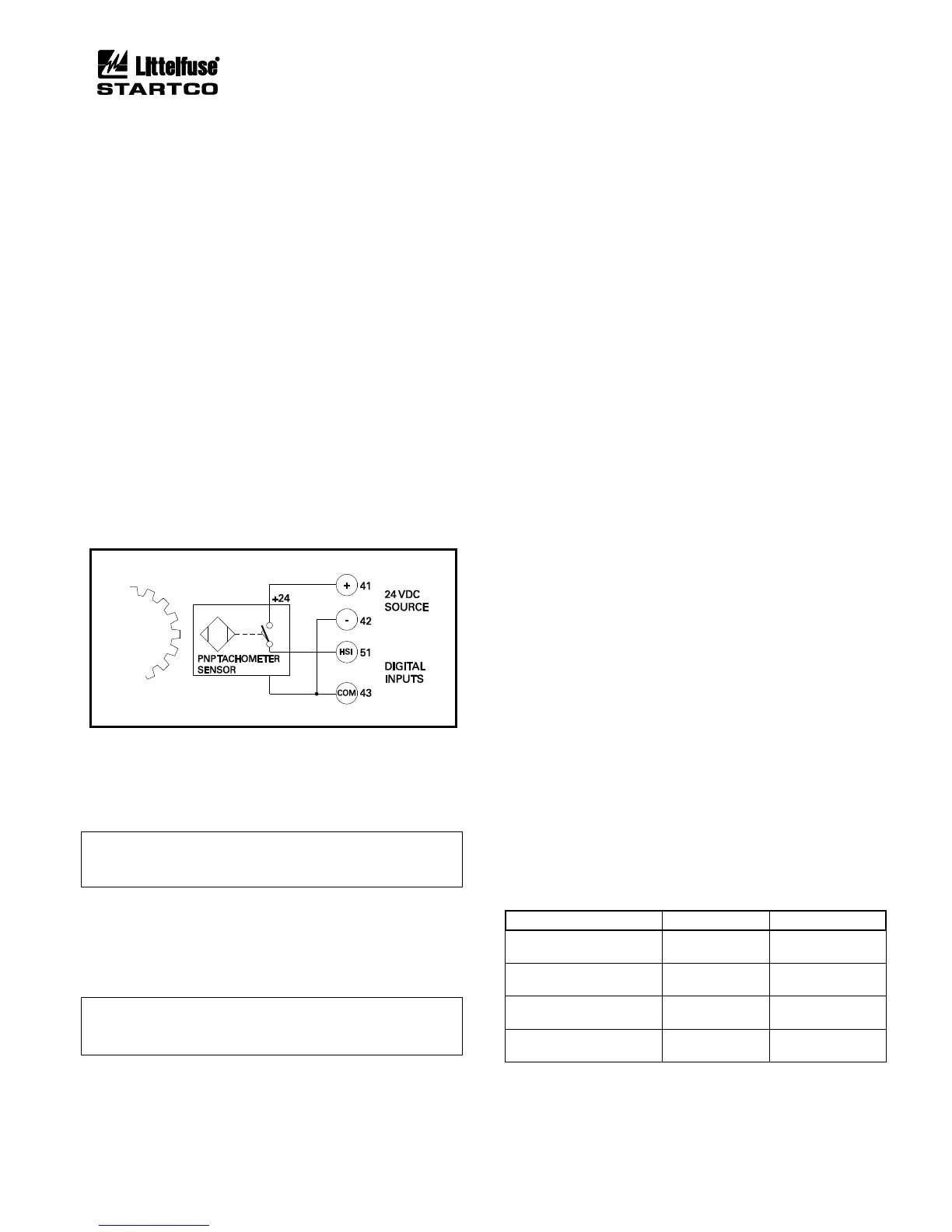

3.2.1.4.4 TACHOMETER INPUT (HSI)

A tachometer sensor can be used to provide motor-

speed measurement. Connect a logic-output PNP

tachometer as shown in Fig. 3.7.

FIGURE 3.7 Digital Tachometer Input (HSI).

3.2.1.5 ANALOG INPUT (AN IN)

The analog input (terminal 52 and 53) is a 4-20-mA

current input with a 100-Ω input impedance.

NOTE: The analog input is referenced to an internal

supply with 100-kΩ resistors. Maximum common-mode

voltage is ± 5 Vdc with respect to MPS-CTU terminal 4.

3.2.1.6 ANALOG OUTPUT (AN OUT)

The analog output is a self-powered current-source

output. The current source output is the “+” (terminal 39)

and the common is “−” (terminal 40).

NOTE: The analog output (terminal 40) is internally

referenced to the 24-Vdc source (terminal 42) and the I/O

supply (terminal 56).

3.2.1.7 PTC INPUT

Terminals 54 and 55 are provided for PTC over-

temperature protection. See Section 9 for specifications.

3.2.1.8 IRIG-B INPUT

Terminals 61 and 62 are used for an IRIG-B time-code

signal. When an IRIG-B signal is detected, the real-time

clock (RTC) synchronizes with it. The user must set the

MPS date value because the IRIG-B day-of-the-year

parameter is not supported.

If the time-code generator does not have a local-time

adjustment, the IRIG Offset set points can be used to

adjust the hour and minute values so that the MPS will

read local time.

3.2.1.9 I/O MODULE COMMUNICATION

The I/O module communications interface (terminals

56 through 60) is used to support optional modules. The

connector labeled Operator Interface on the MPS-CTU

top panel is in parallel with terminals 50 to 56. It is used

for direct MPS-OPI mounting. See Section 2.3.

I/O module communication is based on the 2-wire

multi-drop RS-485 standard. Overall line length must not

exceed 1.2 km (4,000’). For line lengths exceeding

10 m (33’), 150-Ω terminations are required at the cable

ends. See Fig. 3.9.

3.2.1.10 RS-485 NETWORK COMMUNICATIONS

Terminals 35, 36, and 37 are used for the standard

RS-485 interface. See Section 4.2.15.

3.2.2 MPS-OPI CONNECTIONS AND ADDRESS SELECTION

Connect the MPS-OPI to the MPS-CTU using shielded

cable (Belden

®

3124A or equivalent). The 24-Vdc supply

for the MPS-OPI is provided by the MPS-CTU. The

cable shield must be connected at both ends so that

MPS-OPI transient protection is operational. See Fig. 3.9.

The MPS-OPI has two switches to select its network

address. See Figs. 2.2 and 3.8. Up to three MPS-OPI

modules can be connected to the I/O MODULE bus, and

each active OPI must have a unique address. If one OPI

is used, address 1 must be used. If two OPI's are used,

addresses 1 and 2 must be used. If three OPI's are used,

addresses 1, 2, and 3 must be used.

Table 3.1 and Fig. 3.8 shows the addressing selection

format.

TABLE 3.1 MPS-OPI ADDRESS SELECTION

Loading...

Loading...