Page 5-4

MPS Motor Protection System Rev. 6-F-022117

Protective Functions

5.2.2 LOCKED-ROTOR TIMES

In all cases, values for T

H

and T

C

should be obtained

from the motor manufacturer. The following information

is provided to assist in selecting values for T

H

and T

C

only

if manufacturer data is not available.

Heater-style overload elements are available as

Class 10, Class 20, or Class 30. Class 20 is recommended

for general applications, Class 10 is used for motors with

short locked-rotor time capability, and Class 30 is used in

high-inertia applications to allow additional accelerating

time where motors are within Class-30 performance

requirements. These overloads can be replicated by

setting T

C

= 10, 20, or 30 s; T

H

= 0.1 s; and Locked-Rotor

Current = 6.00 x FLA.

An induction motor built to the NEMA MG 1 standard

is capable of:

• two starts in succession (coasting to rest between

starts) with the motor initially at ambient temperature

(cold start)

• one start with the motor initially at a temperature not

exceeding its rated-load operating temperature (hot

start).

Since the connected load has a direct influence on

motor heating during a start, NEMA MG 1 defines the

load torque and the load inertia (Wk

2

) for these starts as a

function of the motor’s rated power and synchronous

speed. To satisfy the cold-start requirement, a start must

not use more than 50% thermal capacity. To satisfy the

hot-start requirement, used thermal capacity at steady

state must be less than 50%.

If the thermal model in the MPS has the correct value

of T

C

and if Used I

2

t increases by 50% during a start, the

load is equal to the NEMA-defined load and two starts

from cold will be permitted. If Used I

2

t increases by more

than 50% during a start, the load is greater than the

NEMA-defined load and two starts from cold should not

be permitted — a delay is required between starts. The

appropriate delay can be obtained by enabling I

2

t Start

Inhibit and setting the I

2

t Inhibit Level equal to 100%

minus the I

2

t used during a start (a slightly lower level is

recommended to allow for supply and load variations). If

Used I

2

t increases by less than 50% during a start, the

load is less than the NEMA-defined load and two starts

from cold will be permitted.

The magnitude of T

H

relative to T

C

determines if a hot

start will be permitted if I

2

t Start Inhibit is enabled and the

I

2

t Inhibit Level is set as described above. If Used I

2

t

increases by 50% or less during a start, a hot start will be

permitted if T

H

is equal to or greater than 50% of T

C

.

Increasing T

H

above 50% of T

C

is not recommended

unless specific information is available with respect to T

H

.

5.2.3 EMERGENCY THERMAL RESET

OPI Menu: Messages | Emerg I2t Reset | Reset I2t Memory

Emergency Thermal Reset (ETR) sets Used I

2

t to 0%,

resets starts-per-hour variables, and disables PTC and

RTD temperature trips. Program access (password) is

required. Disabled-temperature protection is indicated by

t

°

Disabled by ETR in the Status Messages display. If

PTC or RTD temperature protection is not enabled, t

°

Disabled by ETR will not be displayed. Stator RTD or

PTC trips are reset when ETR is performed regardless of

measured temperatures. Temperature protection must be

re-enabled in the Messages | Emerg I

2

t Reset | Reenable

Temp menu, or by cycling supply voltage.

Temperature alarms and sensor verification remain

enabled during ETR.

NOTE: Temperature protection is not automatically re-

enabled after an Emergency Thermal Reset.

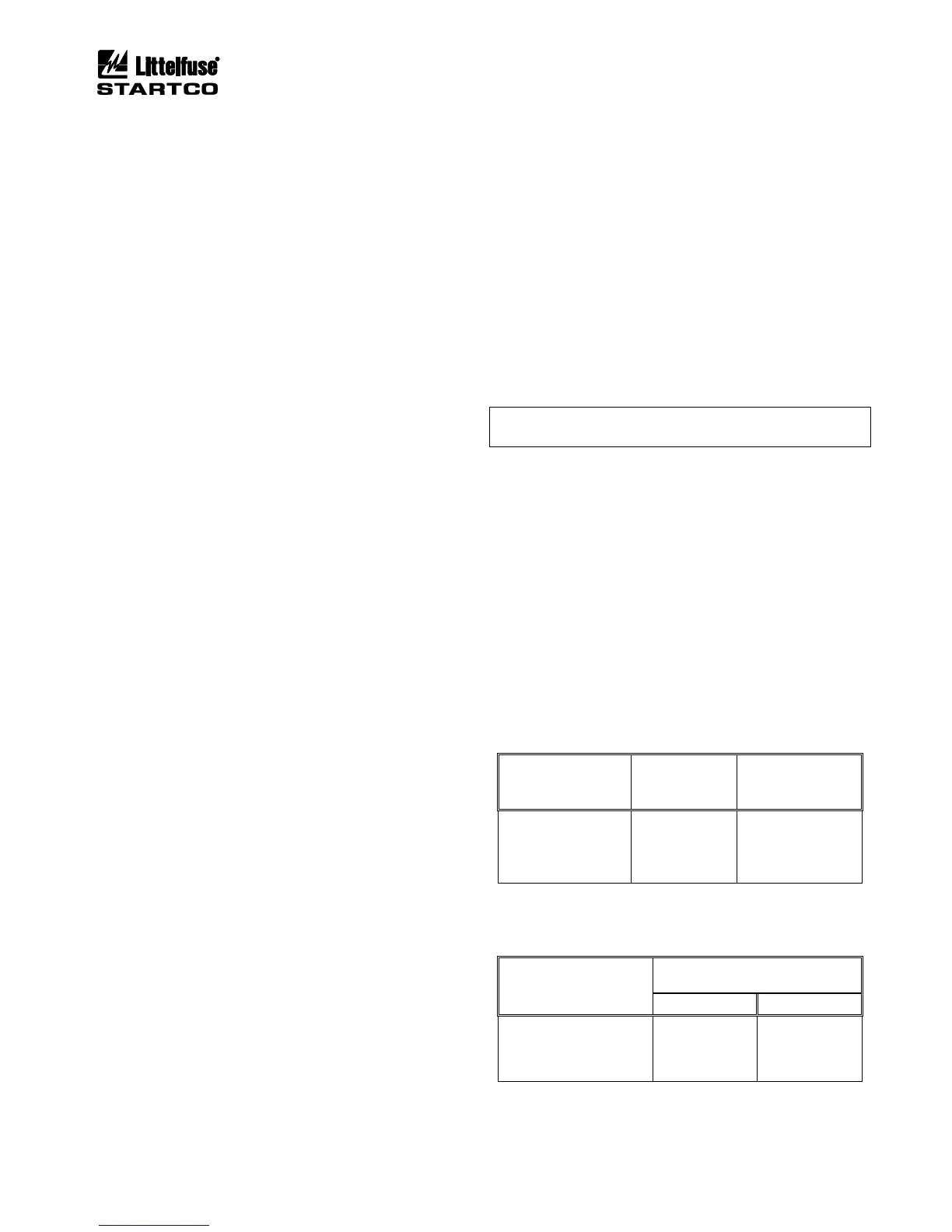

5.3 OVERCURRENT

OPI Menu: Setup | Protection | Overcurrent

Overcurrent protection is based on the largest

fundamental-frequency component (DFT) of the three

phase currents. An alarm-level setting is not provided.

When enabled, overcurrent protection is active at all

times. It is not bypassed during a start.

Trip Level ............................. 1.00 to 15.00 x CT-Primary

Rating (I

p

)

Trip Delay (TD) .................... 0.00 to 10.00 s

(See Tables 5.1 and 5.2)

Protection .............................. Enable/Disable Trip1, 2, 3

Measurement Method ........... DFT

TABLE 5.1 TRIP TIME

Loading...

Loading...