Page 3-5

MPS Motor Protection System Rev. 6-F-022117

System Wiring

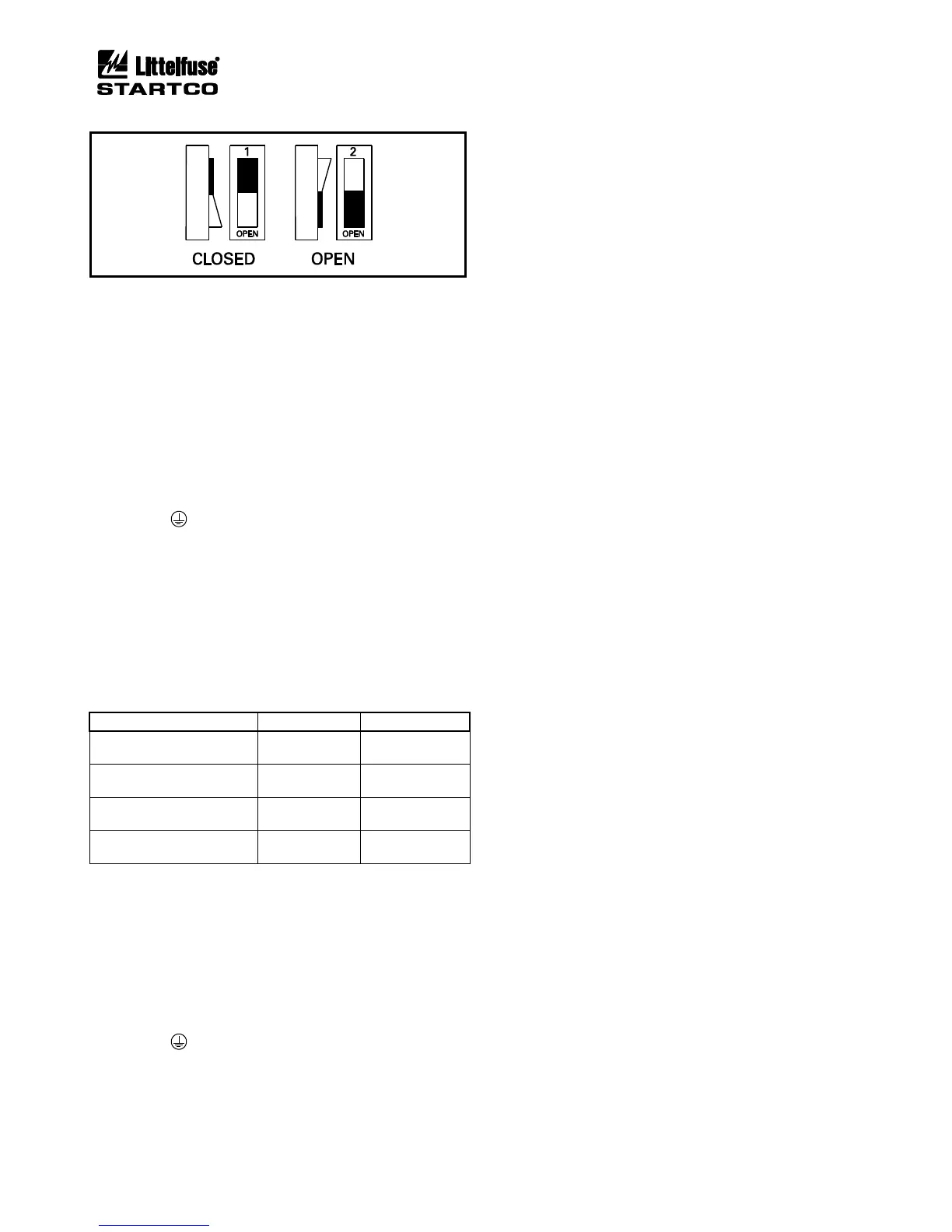

FIGURE 3.8 Address Selection Switch Detail.

3.2.3 MPS-RTD CONNECTIONS AND ADDRESS SELECTION

MPS-RTD terminal blocks accept 24 to 12 AWG

(0.2 to 2.5 mm

2

) conductors.

Connect the MPS-RTD to the MPS-CTU using the

four-conductor shielded cable (Belden 3124A or

equivalent) as shown in Fig. 3.9. The MPS-CTU 24-Vdc

supply can power up to three MPS-RTD modules.

Connect RTD’s to the MPS-RTD as shown in Fig 3.9.

When the RTD module is installed in a motor junction

box, RTD-lead shielding is not required.

Connect the surge-protection (SPG) terminal 20 to

terminal 19 ( ), and earth terminal 19.

The MPS-RTD has two switches to select its network

address. See Figs. 3.8 and 3.10. Up to three MPS-RTD

modules can be connected to the I/O MODULE bus, and

each RTD-module address must be unique. If one module

is used, address 1 must be used. If two RTD modules are

used, addresses 1 and 2 must be used. If three RTD

modules are used, addresses 1, 2, and 3 must be used.

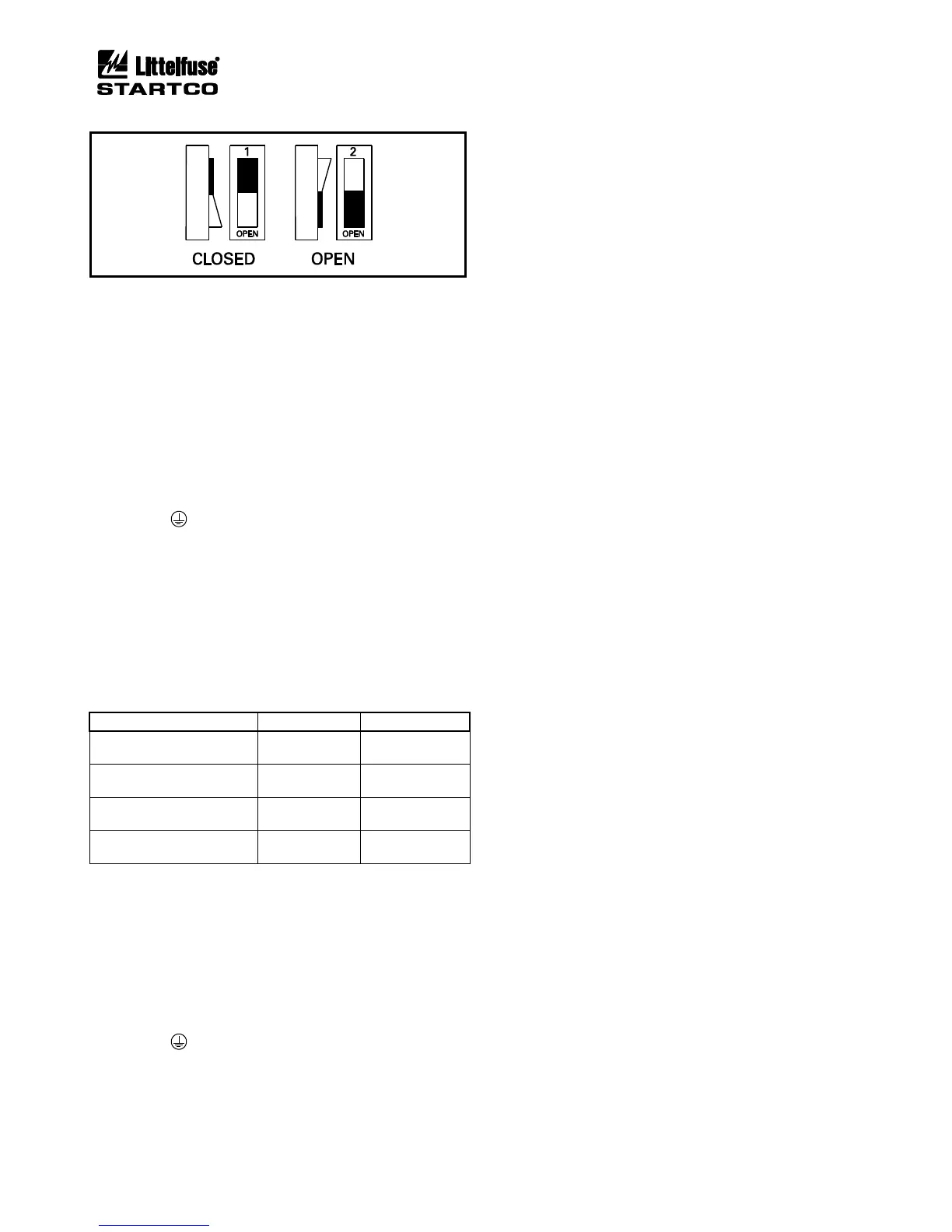

Table 3.2 shows the addressing selection format.

TABLE 3.2 MPS-RTD ADDRESS SELECTION

3.2.4 MPS-DIF CONNECTIONS

The MPS-DIF CT-input terminal blocks accept 22 to

10 AWG (0.3 to 4.0 mm

2

) conductors. The remaining

MPS-DIF clamping blocks accept 24 to 12 AWG (0.2 to

2.5 mm

2

) conductors.

Connect the MPS-DIF to the MPS-CTU using four-

conductor shielded cable (Belden 3124A or equivalent) as

shown in Fig. 3.9.

Connect the surge-protection (SPG) terminal 15 to

terminal 14 ( ), and earth terminal 14.

3.2.4.1 CORE BALANCE

The core-balance connection is shown in Fig. 3.11. To

minimize power-cable and CT-lead length, both the

differential CT’s and the MPS-DIF can be located near

the motor. The primary rating of the differential CT does

not have to match the phase-CT primary rating and is

usually selected with a lower ratio resulting in more

sensitive differential protection. The core-balance

method avoids CT-matching issues and is the preferred

connection.

3.2.4.2 MPS SUMMATION

The MPS summation connection uses three phase CT’s

and three differential CT’s as shown in Fig. 3.12. Both

CT ratio and CT-saturation characteristics must be

matched to avoid differential currents under motor

starting and running conditions. The MPS-DIF module

should be located near the MPS-CTU to minimize CT

wire length. It is preferred to use three dedicated phase

CT’s and three core-balance differential CT’s as

described in Section 3.2.4.1.

For the delta connection, the MPS FLA Rating is set

equal to the motor’s full-load current multiplied by √3.

Power, power factor and energy measurements are not

correct for the delta connection.

3.2.4.3 DIF SUMMATION

The DIF summation connection uses six differential

CT’s as shown in Fig. 3.13. Both CT-ratio and CT-

saturation characteristics must be matched to avoid

differential currents under motor starting and running

conditions. It is preferred to use three core-balance CT’s

as described in Section 3.2.4.1. This six CT connection

allows the CT’s and MPS-DIF to be placed near the motor

to minimize power-cable and CT-lead length.

3.2.5 DIELECTRIC-STRENGTH TESTING

Dielectric-strength testing should be performed only on

CT inputs, PT inputs, output relays, and digital inputs.

Unplug all other I/O and remove the SPG connection

(terminal 4 to terminal 4A) on the MPS-CTU during

dielectric-strength testing.

Loading...

Loading...