Page 5-10

MPS Motor Protection System Rev. 6-F-022117

Protective Functions

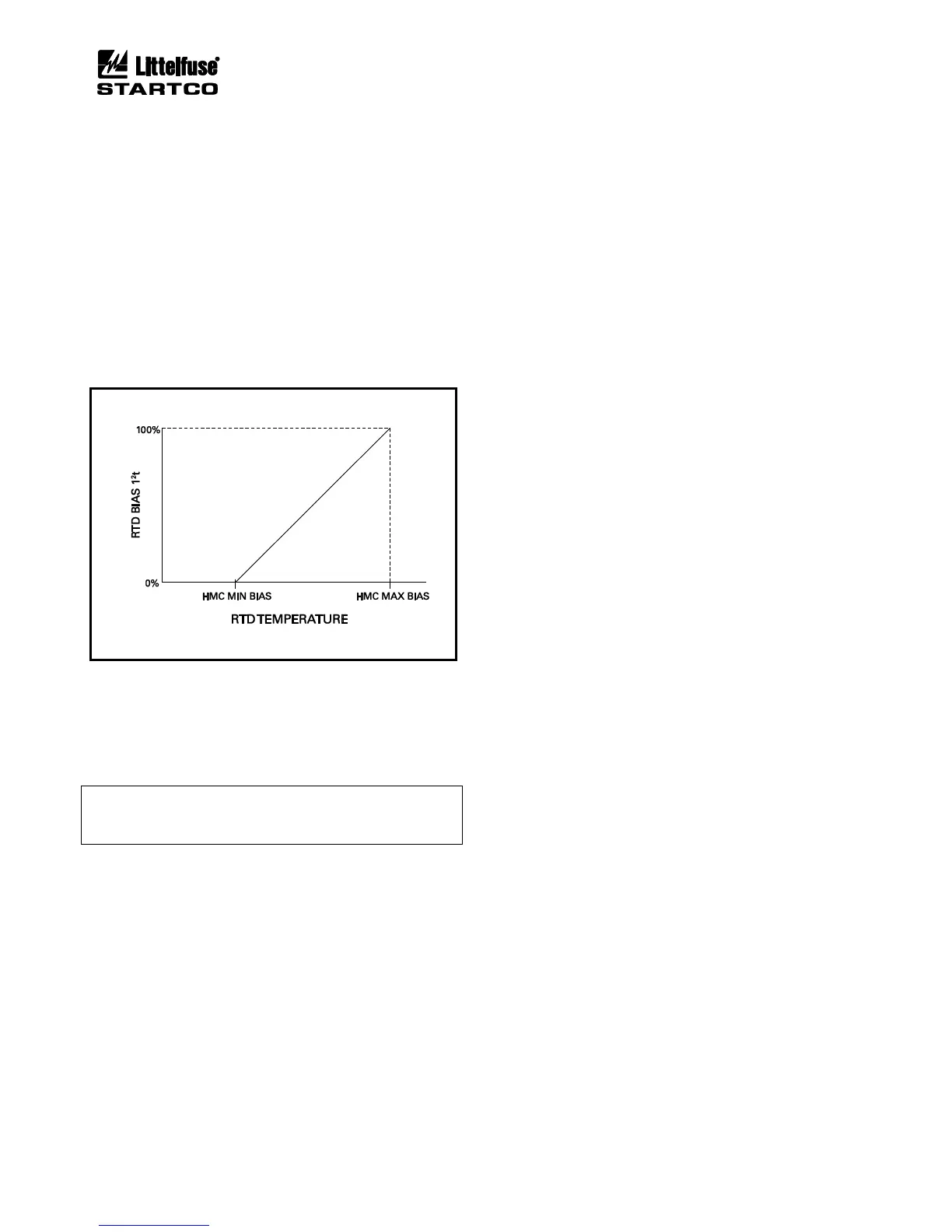

5.28 HOT-MOTOR COMPENSATION

OPI Menu: Setup | Protection | RTD Temperature

If hot-motor compensation (HMC) is enabled, the

maximum stator-RTD temperature is used to bias the

thermal model by increasing Used I

2

t when the RTD

temperature is greater than the thermal-model

temperature.

Two set points are used to define the compensation.

See Fig. 5.3. HMC Minimum Bias is the stator

temperature where compensation begins at 0% I

2

t. HMC

Maximum Bias is the stator temperature where

compensation ends at 100% I

2

t.

Although the bias calculation is based on 0% and 100%

I

2

t values, the Used I

2

t adjustment is limited to 90% I

2

t.

An actual overload condition is required to cause a trip at

100% I

2

t.

FIGURE 5.3 Used I

2

t Bias Curve.

HMC Minimum Bias ............ 40.00 to 200.00°C (104°F to

392°F)

HMC Maximum Bias ........... 40.00 to 200.00°C (104°F to

392°F)

Protection .............................. Enable/Disable

NOTE: Hot-motor compensation will not be active unless

the HMC High set point is at least 10°C above the HMC

Low set point.

5.29 ANALOG INPUT

OPI Menu: Setup | Analog Input | 4–20 Input Type

The analog input function is selectable as Metering

Only, Protection, Sync to ASD, or Motor Speed.

5.29.1 PROTECTION

OPI Menu: Setup | 4-20 Analog In | Protection

The protection input has high-level and low-level trip

and alarm set points. A high-level trip or alarm occurs

when the 4-20-mA input exceeds the high-level trip or

alarm set point, and a low-level trip or alarm occurs when

the 4-20-mA input is lower than the low-level trip or

alarm set point.

Trip action is fixed at Trip1 and alarm action is fixed at

Alarm1.

High Level Trip .................... 0.10 to 20.00 mA

Low Level Trip ..................... 0.10 to 20.00 mA

Trip Delay ............................. 0.01 to 100.00 s

High Level Alarm ................. 0.10 to 20.00 mA

Low Level Alarm ................. 0.10 to 20.00 mA

Alarm Delay ......................... 0.01 to 100.00 s

5.29.2 SYNCHRONIZE TO ASD

OPI Menu: Setup | 4-20 Analog In | Sync to ASD

When Sync to ASD is selected, the MPS uses the

4-20-mA input to set the internal sampling rate for current

and voltage inputs so that protection and metering

functions use accurate RMS and DFT values from 10.00

to 70.00 Hz.

4-mA Frequency (lower) ...... 0.00 to 70.00 Hz

20-mA Frequency (upper) .... 0.00 to 70.00 Hz

Frequency Range .................. 10.00 to 70.00 Hz

5.29.3 MOTOR SPEED

OPI Menu: Setup | 4-20 Analog In | Motor Speed

When the analog-input type is selected as Motor Speed,

the 4-20-mA analog input is used as the speed input. This

selection overrides the selections for the high-speed

tachometer input and failure-to-accelerate protection uses

the analog input as the source of speed information.

4-mA Speed .......................... 0.00 to 100% Sync Speed

20-mA Speed ........................ 0.00 to 100% Sync Speed

5.29.4 METERING ONLY

When the analog-input type is selected as Metering

Only, an analog input does not affect MPS operation, but

its value can be observed in the Metering menu and with a

communications network.

Loading...

Loading...