CHAPTER 8: OPERATION 87

TRYTON 107/112

8. CYCLE AUTOMATIC

8.1. Description

The amount of time the bar-feeder can run unattended will depend directly on the frequency with which the

operator fills the barrel. This operation can be effected during the production cycle.

Each time the automatic sequence of the bar feed system needs to be started up, it is advisable to check

the following elements:

• The bars must be butted against the rear stop in the barrel.

• The collet of the bar feed system must correspond to the diameter of the bar.

• The pushing torque must correspond to the material to be loaded

• The front rest (option) must be correctly adjusted (opening and closing) and its elements must be

adapted to the shape of the material.

• On the lathe, the clamping device must correspond to the material to be loaded

• Material must be placed into the lathe clamping device.

Note : under certain conditions, it is possible to perform manual movements during the

automatic cycle.

Depending on the lathe configuration and the bar feed system, the automatic cycle may vary.

8.2. Production cycle

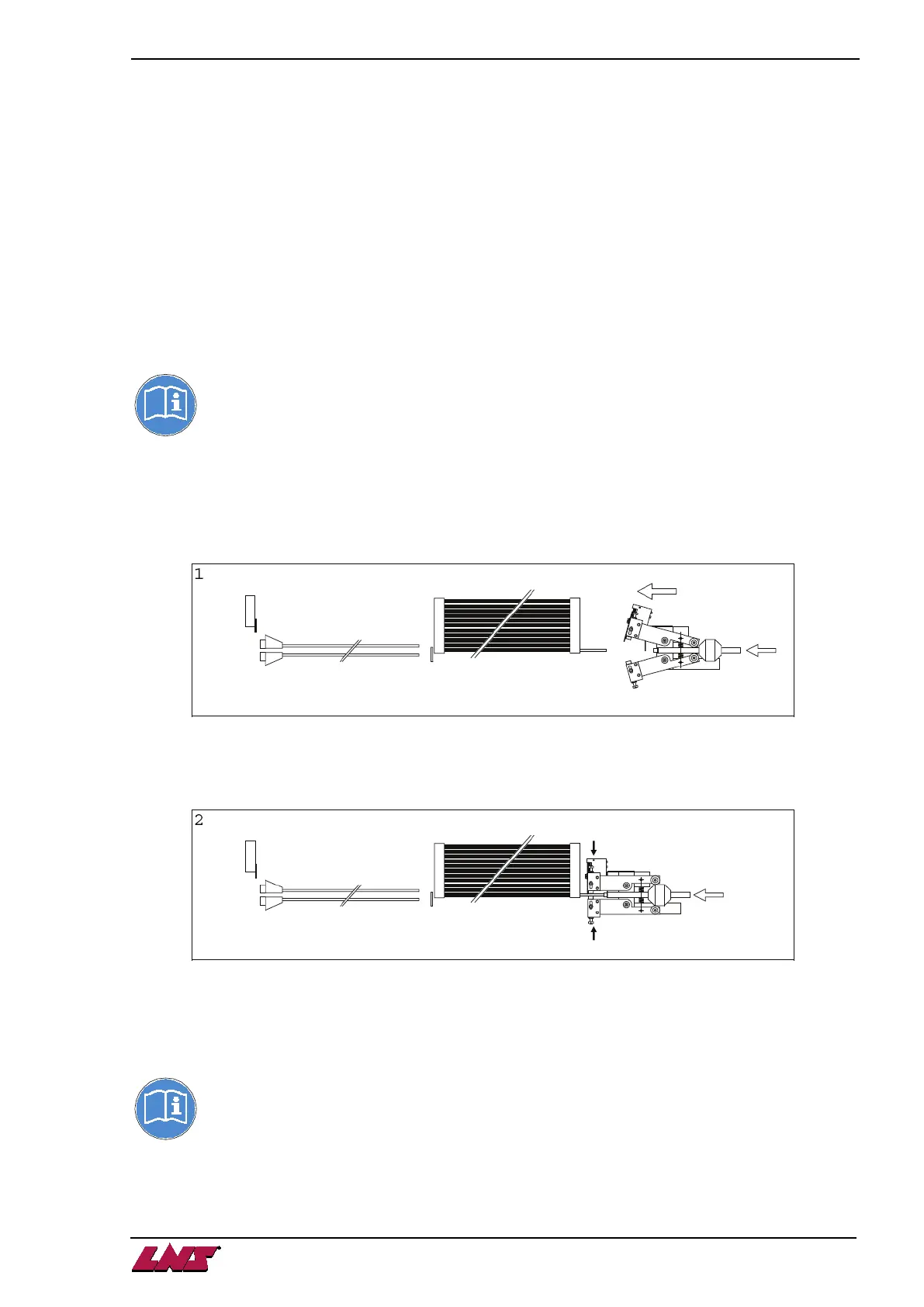

1. The material is in the barrel, in the axis of the pusher and the spindle.

The mobile vice and the connector advance.

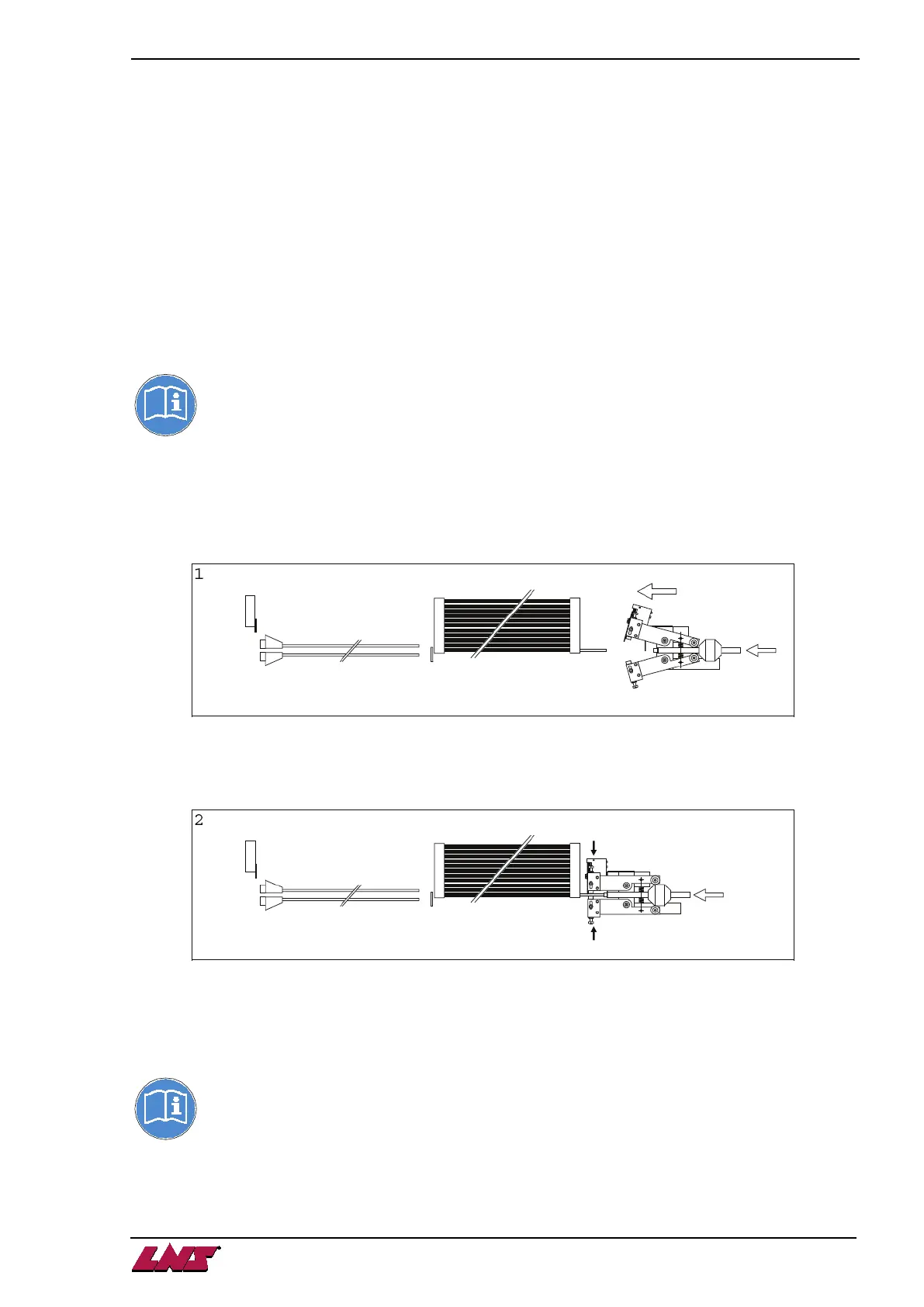

2. When the mobile vice reaches the end-stop, the cam separates the roller-bearings and the jaws

clamp on the rod.

The connector advances and inserts the bar into the pusher chuck jaw.

3. The mobile vice continues on its way and will move up against the barrel.

The hydraulic pump starts up and pushes the pusher into the barrel.

Only for CNC lathe type : on leaving the barrel, the bar pushes the positioning stop and the

measuring path begins.

Only for CAM lathe type: the timer set into parameters starts.

Note : If the barrel is empty, the bar feeder stops when the jaws clamp to insert the bar into

the pusher collet.

Loading...

Loading...