Before start-up

- 40 - 10.13

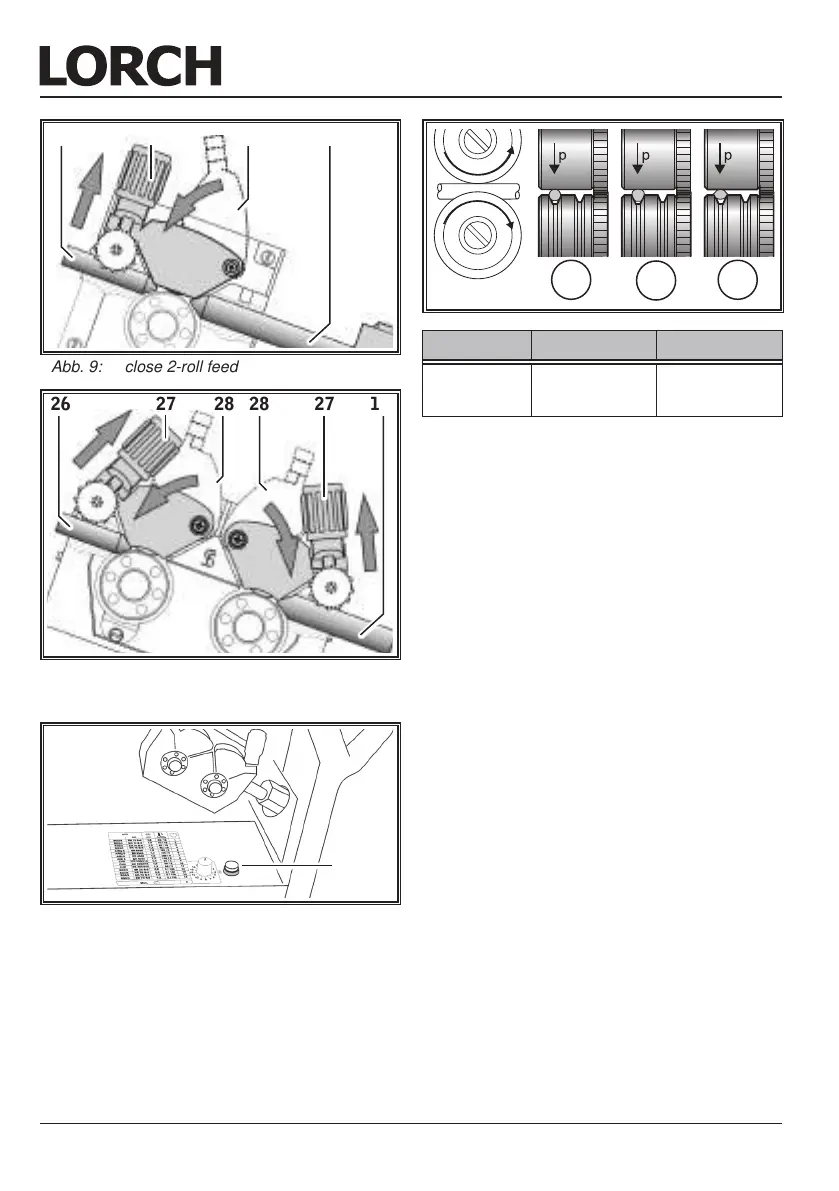

26 27 28 11

25

Abb. 9: close 2-roll feed

26 27 27 112828

25

25

Abb. 10: close 4-roll feed

Turn on the machine at mains switch 9.

29

Abb. 11: Wire feed button

Press wire feed button 29.

Adjust the contact pressure using the reg-

ulation screws 27 so that wire feed rollers

25 just slip when the welding wire spool is

stopped. The wire must not be jammed or

deformed.

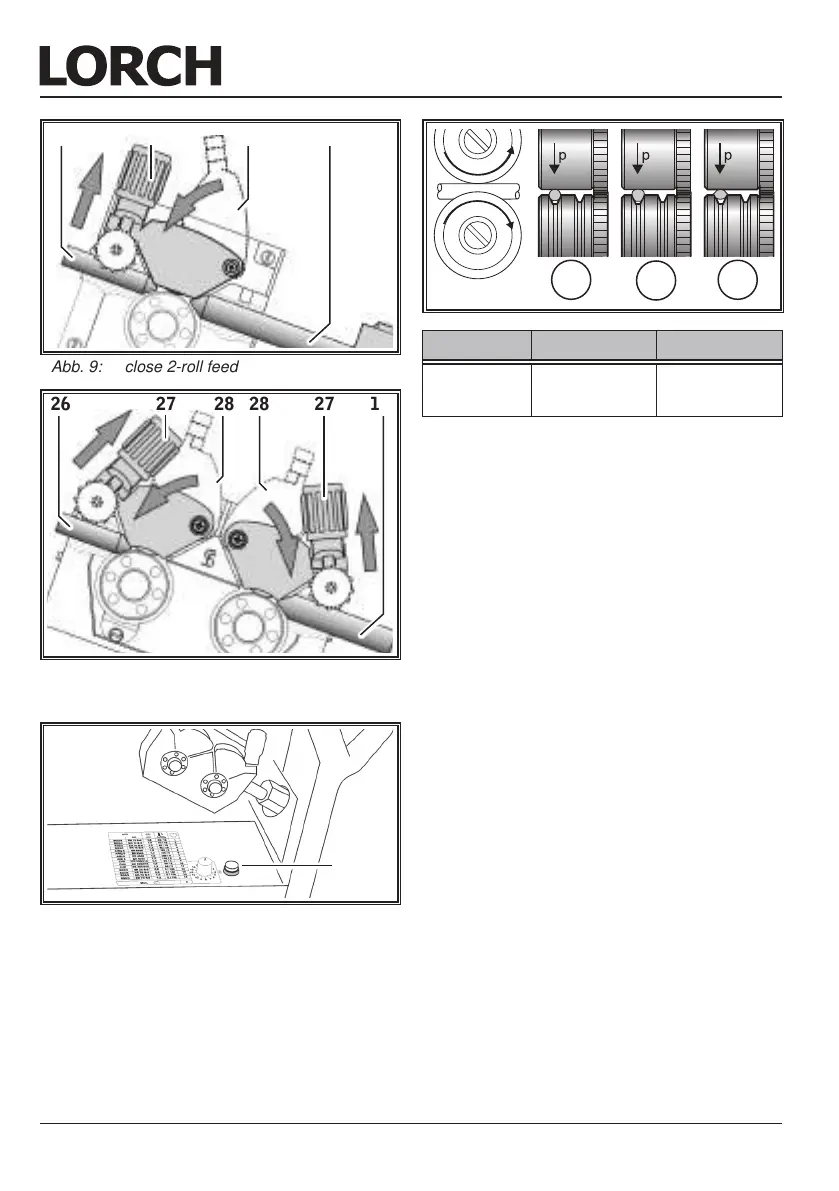

A

B

C

A B C

Correct Contact pres-

sure too high

Wrong wire

feed roller

Abb. 12: Wire feed rollers

Note for wire feed unit with 4 rollers:

Adjust the contact pressure of the wire

feed rollers 25 on the side of the inlet noz-

zle 26 to be less than on the side of the

central socket 11 in order to keep the wire

electrode under tension in the wire feed

unit.

Push the wire feed button 29 until the wire

protrudes from the torch neck by about 20

mm.

Screw the contact tip matching the wire

thickness into the torch and cut off the

protruding end of the wire.

Loading...

Loading...