Technical data

- 54 - 10.13

16 Repair and maintenance

Please heed the current safety

and accident prevention regu-

lations during all maintenance

and repair work.

16.1 Check regularly

Check the following points for damage

before starting up the welding machine:

– Mains plug and cable

– Welding torch and connections

– Ground cable and connection

Blow out the welding machine every two

months.

Switch the machine off

Disconnect the mains plug

Unscrew both side panels of the unit

Blow out the welding machine with dry,

low pressure compressed air. Avoid blow-

ing directly on the electronic components

from a short distance, to prevent damage

Screw the two side panels onto the ma-

chine back again

Never make repairs or technical

changes yourself.

In this case the manufacturer’s

warranty is no longer valid.

If you experience problems or

need repairs, contact a dealer au-

thorised by Lorch.

16.2 Torch care

Remove the weld spatter from inside the

gas nozzle using suitable tongs.

Spray the inside surface of the gas noz-

zle with a releasing agent, or use nozzle

protection paste.

9 This will prevent weld spatter from being

burnt on.

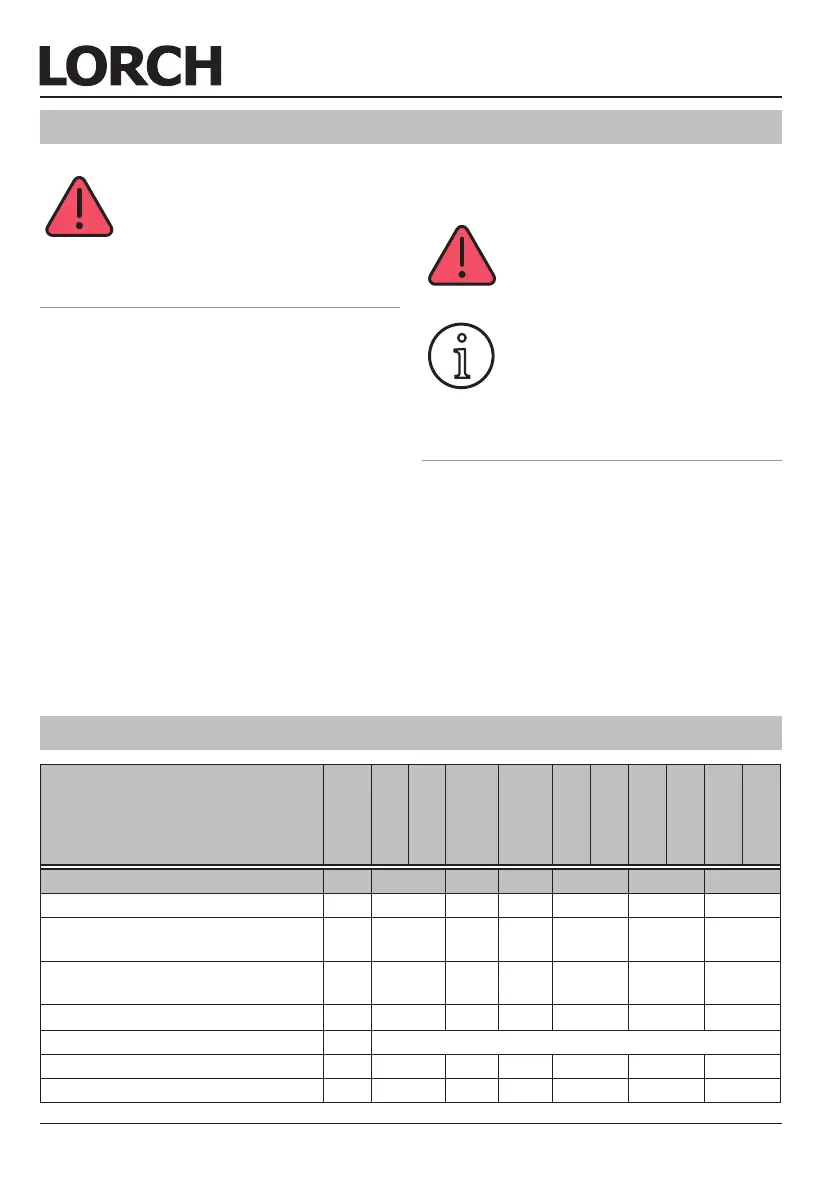

Technical data

1

M 150 CuSi

BasicPlus

M 150 CuSi

ControlPro

M 170

BasicPlus

2

M 200 CuSi

ControlPro

M 210

BasicPlus

2

M 210

ControlPro

2

M 250

BasicPlus

M 250

ControlPro

M 300

BasicPlus

M 300

ControlPro

Welding

Welding range (I

2min

..I

2max

)

A 15..150 25..170 15..200 25..210 30..250 30..300

Welding range (U

2min

..U

2max

)

V 14,8..

21,5

15,3..

22,5

14,8..

24,0

15,3..

24,5

15,5..

26,5

15,5..

29,0

No-load voltage

V 14,4..

26,9

16,7..

38,0

14,4..

32,5

14,5..

40,3

16,3..

35,1

16,3..

40,2

Voltage setting

steps

7 6 12 12 12 12

Slope characteristic constant voltage characteristic line

ED 100 %

A 100 70 100 75 150 170

ED 60 %

A 120 85 130 90 185 205

17 Technical data

Loading...

Loading...