3 - 40

Ü

OCCASIONAL MAINTENANCE

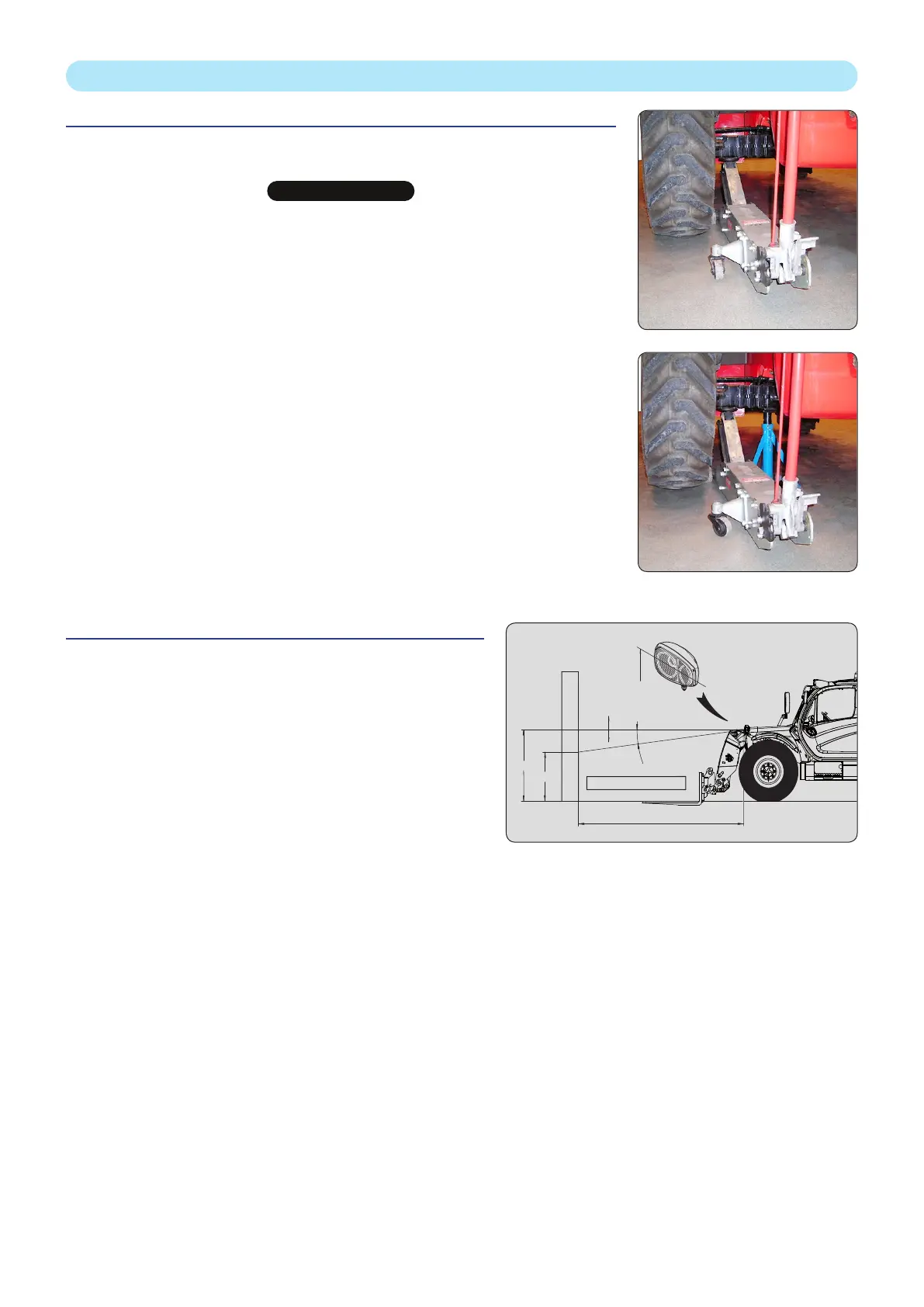

REPLACE Wheels

For this operation, we recommend using the hydraulic jack MANITOU reference 505507

and the safety support MANITOU reference 554772.

t

IMPORTANT

t

In the event of a wheel being changed on the road, secure the environment of the lift truck:

- If possible, stop the lift truck on even and hard ground.

- Shut down the lift truck (e 1 - OPERATING AND SAFETY INSTRUCTIONS: DRIVING

INSTRUCTIONS UNLADEN AND LADEN).

- Turn on the emergency lights.

- Apply wedges to immobilise the lift truck in both directions on the axle opposite

to the wheel to be changed.

- Unlock the nuts of the wheel to be changed.

- Place the jack under the flared axle tube, as near as possible to the wheel and

adjust the jack.

- Lift the wheel until it comes off the ground and put in place the safety support

under the axle.

- Completely unscrew the wheel nuts and remove them.

- Free the wheel by reciprocating movements and roll it to the side.

- Slip the new wheel on the wheel hub.

- Refit the nuts by hand, if necessary grease them.

- Remove the safety support and lower the lift truck with the jack.

- Tighten the wheel nuts with a torque wrench (e 2000 HOUR - PERIODIC

MAINTENANCE - EVERY 2000 HOURS OF SERVICE OR 4 YEARS) for tightening torque.

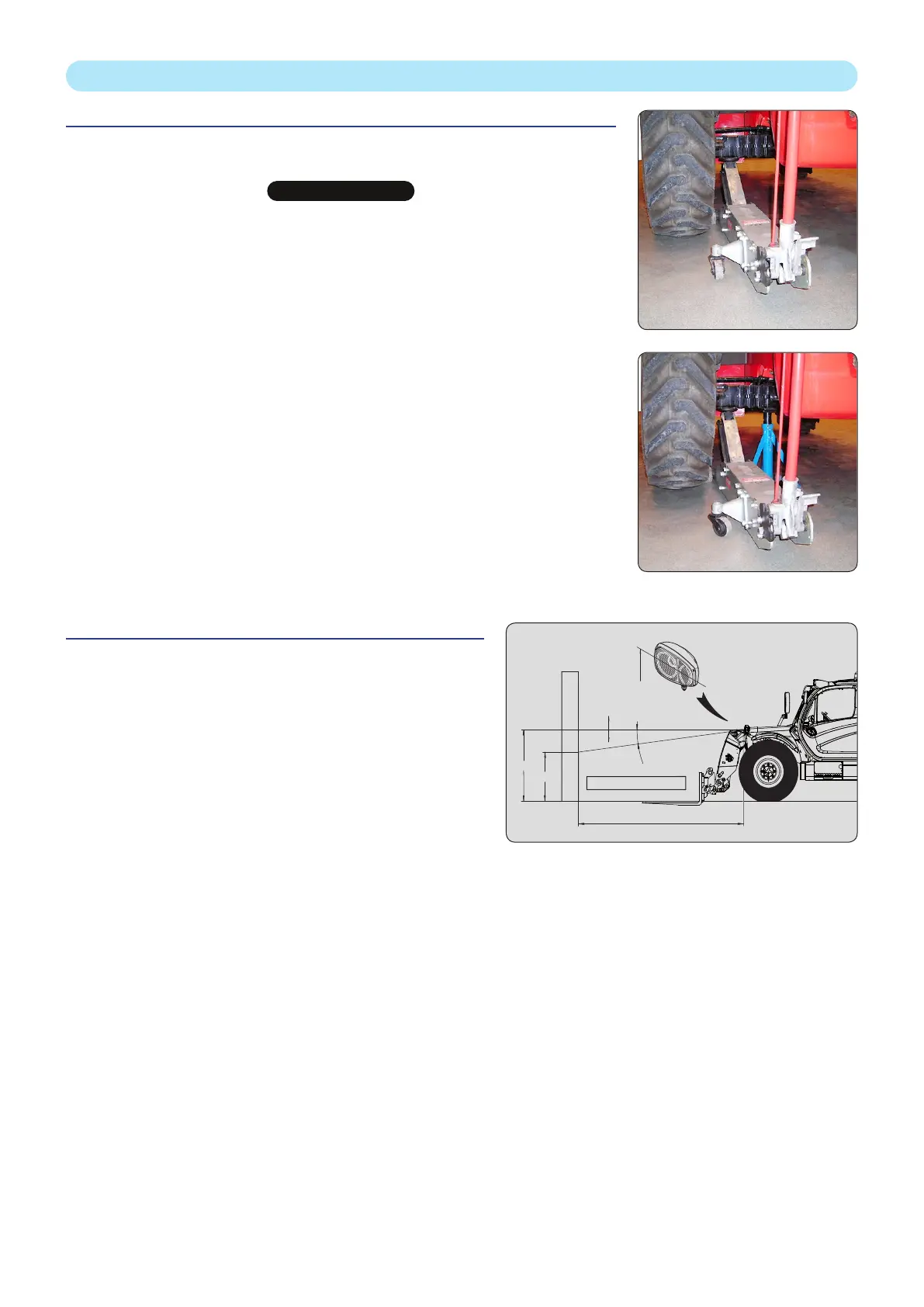

ADJUST Front headlights

RECOMMENDATIONS FOR ADJUSTMENT

(as per standard ECE-76/756 76/761 ECE20)

Set to -2% of the dipped beam in relation to the horizontal line of

the headlamp.

ADJUSTING PROCEDURE

- Place the lift truck unladen and in the transport position, and

perpendicular to a white wall on flat, level ground.

- Check the tyre pressure (

e 2 - DESCRIPTION: TYRES).

- Position the gear selector to neutral.

CALCULATION OF DIPPED BEAM HEIGHT (H2)

•

h1 = Height of the low beams in relation to the ground.

• h2 = Height of the adjusted beam.

• l= Distance between the low beams and the white wall.

+%

-%

l

h1

h2

-2%

h2 = h1 - (l x 2 / 100)

h1

649100 EN-US-AU (20/05/2019)

MLT 961-145 V PLUS L JD ST4 S1

Loading...

Loading...