Manitowoc Published 11-22-17, Control # 257-02 5-49

MLC300 SERVICE/MAINTENANCE MANUAL HOISTS

New Wire Rope—After initial loading, measure and record

the diameter of any new wire rope for comparison to future

inspections (see Maintain a Wire Rope Condition Report on

page 5-46).

The wire rope must be taken out of service when the

reduction from its nominal diameter is more than 5 percent.

Broken Rope Wires

When conducting the periodic comprehensive inspection,

thoroughly clean the wire rope so breaks can be seen. Relax

the rope, move it off “pick-up points,” and flex it as much as

possible. Use a sharp awl to pick and probe between the

wires and strands, lifting any wire which appears loose or

moves excessively. Do not open strands of rotation-resistant

rope.

Wire breaks are typically at the crown of the strands—the

area that contacts the sheave or drum when a load is picked

up. Breaks at the crown will appear as small gaps in a wire.

In comparison, when wires in the valley of a strand break, the

broken ends will rise up and are easier to notice.

NOTE: The daily inspection does not require that the rope

be cleaned or probed.

The wire rope must be taken out of service when it has the

following number of broken wires (see Figure 5-29

for an

explanation of lay length):

• Running Ropes—Six randomly broken wires in one lay

length or three broken wires in one strand in one lay

length.

• Standing Ropes (pendants)—More than two broken

wires in one lay length in sections beyond the end

attachment, or more than one broken wire at the end

attachment (see Figure 5-28

).

• Rotation-resistant rope—Two randomly distributed

broken wires in six-rope diameters or four randomly

distributed broken wires in 30-rope diameters.

• All ropes—One outer wire broken at the point of contact

with the core and protruding or looping out of the rope

structure. Additional inspection is required.

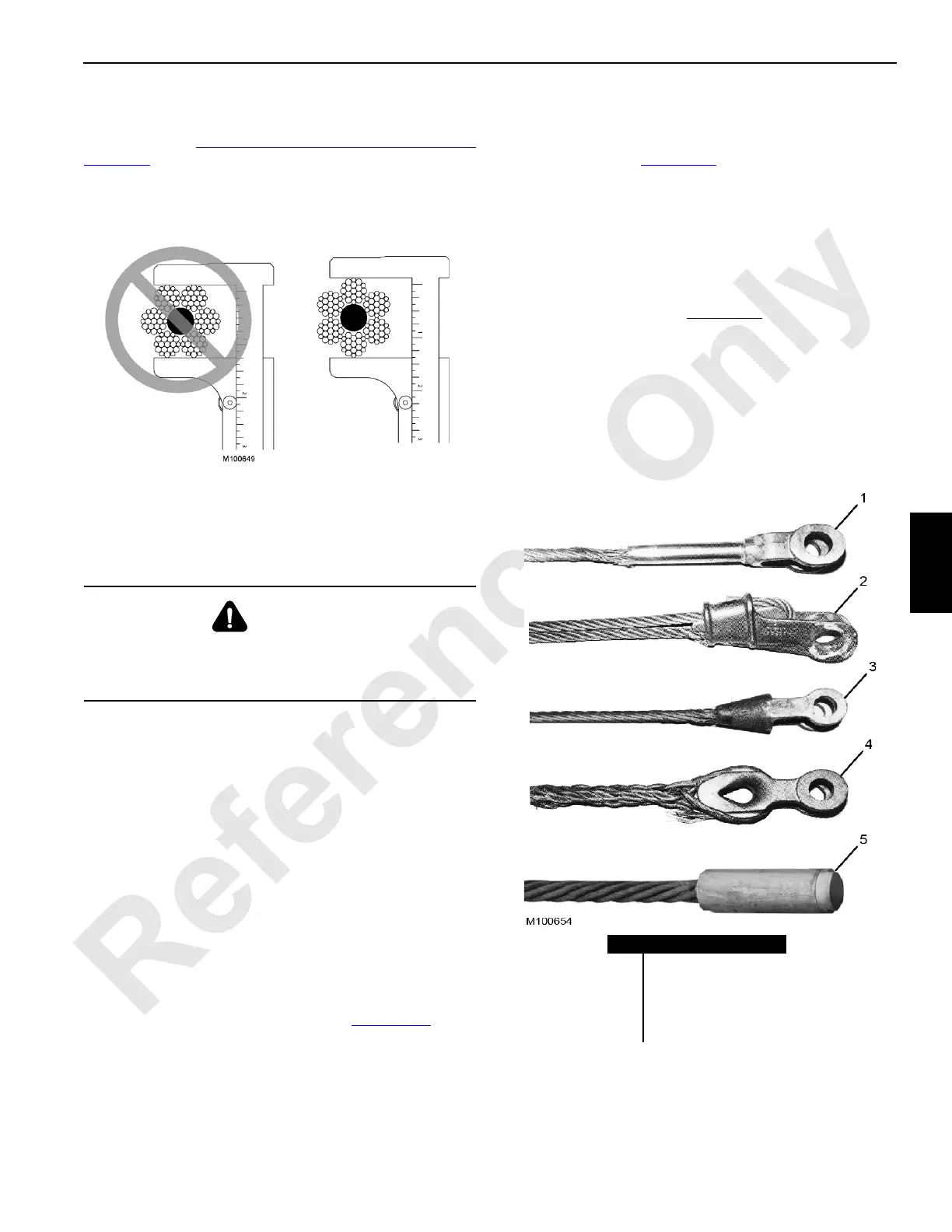

• End attachments (see Figure 5-28

)—When more than

one broken wire appears at the attachment, replace the

rope or cut off the affected area and reattach the fitting.

NOTE: For galvanized bridle strand wire rope pendants,

United States Steel states, “Replacement criteria

for galvanized strand boom suspension pendants

are 25 percent of the outer wires fractured, or 10

percent of the total numbers, whichever comes

first.”

WARNING

Falling Load Hazard!

A broken wire indicates a weakened wire rope. Replace

wire rope when more than one broken wire appears.

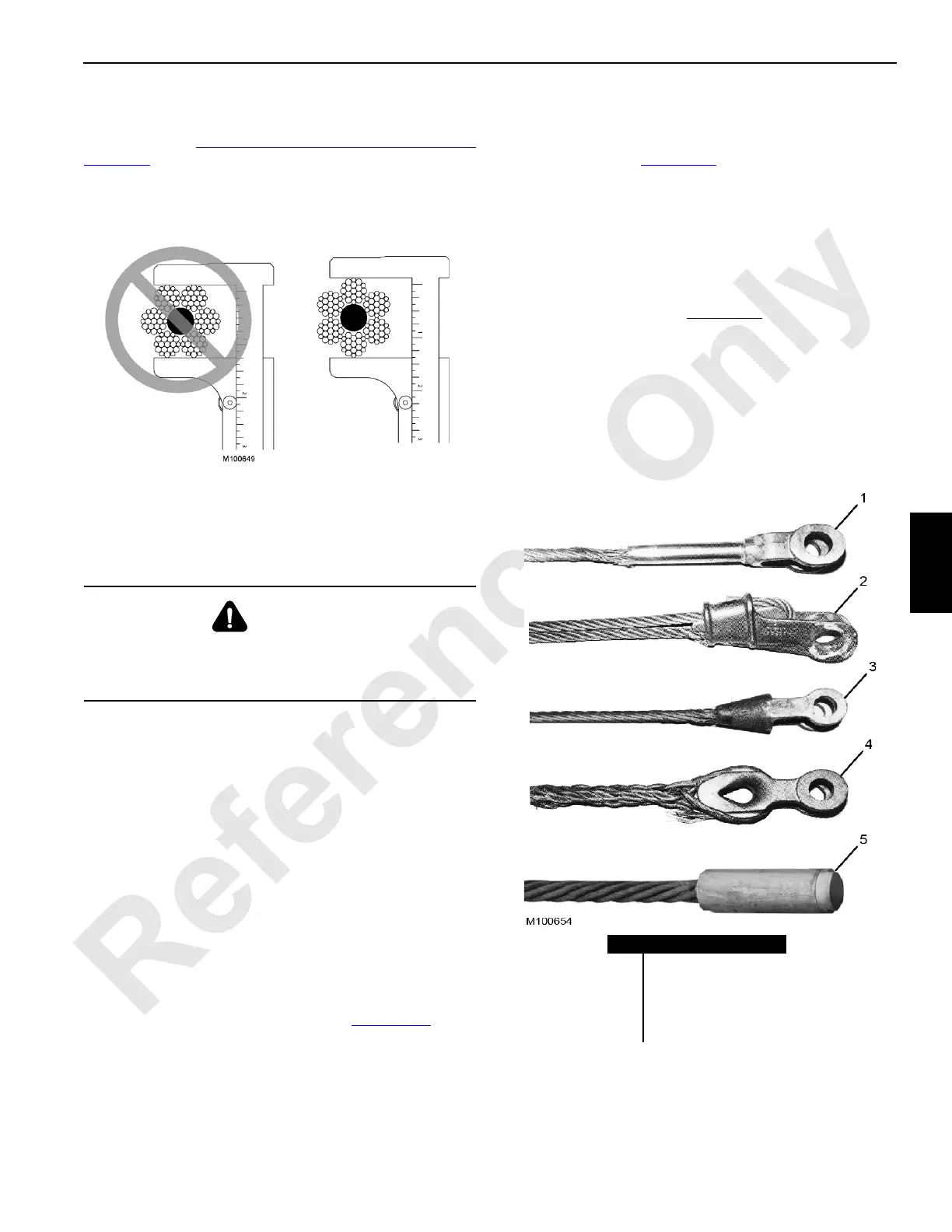

Incorrect

Correct

Measuring Technique

FIGURE 5-27

Item Description

1 Swagged Socket

2 Wedge Socket

3 Poured Zinc Socket

4 Hand-Spliced Socket

5 Button Socket

FIGURE 5-28

Loading...

Loading...