Manitowoc Published 11-22-17, Control # 257-02 8-17

MLC300 SERVICE/MAINTENANCE MANUAL UNDERCARRIAGE

CRAWLER PREVENTIVE MAINTENANCE

Crawler wear cannot be eliminated, but the rate of wear can

be reduced through regular preventive maintenance:

• Lubricate the crawlers as instructed in the Lubrication

Guide supplied with the crane.

• Keep the crawlers clean and avoid dirt buildup when

cutting.

• Keep all mounting bolts tight.

• Keep the treads properly adjusted.

• Inspect the crawler frames, rollers, and treads on a

regular basis.

• Check for oil leaks, excessive wear, cracks, and other

damage. Broken or cracked parts can indicate that the

treads are adjusted too tightly.

• Repair or replace damaged parts immediately to prevent

further damage.

CRAWLER TREAD SLACK MEASUREMENT

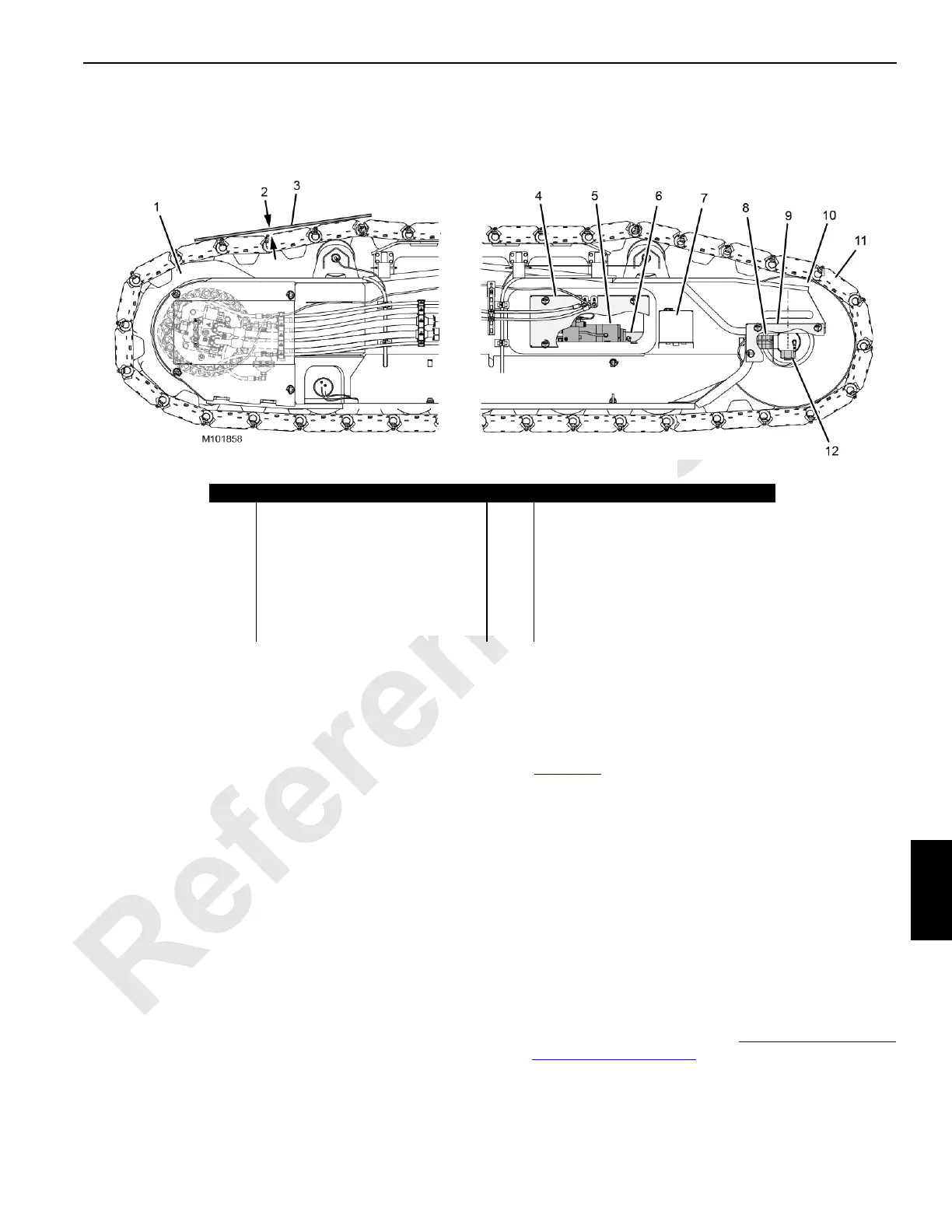

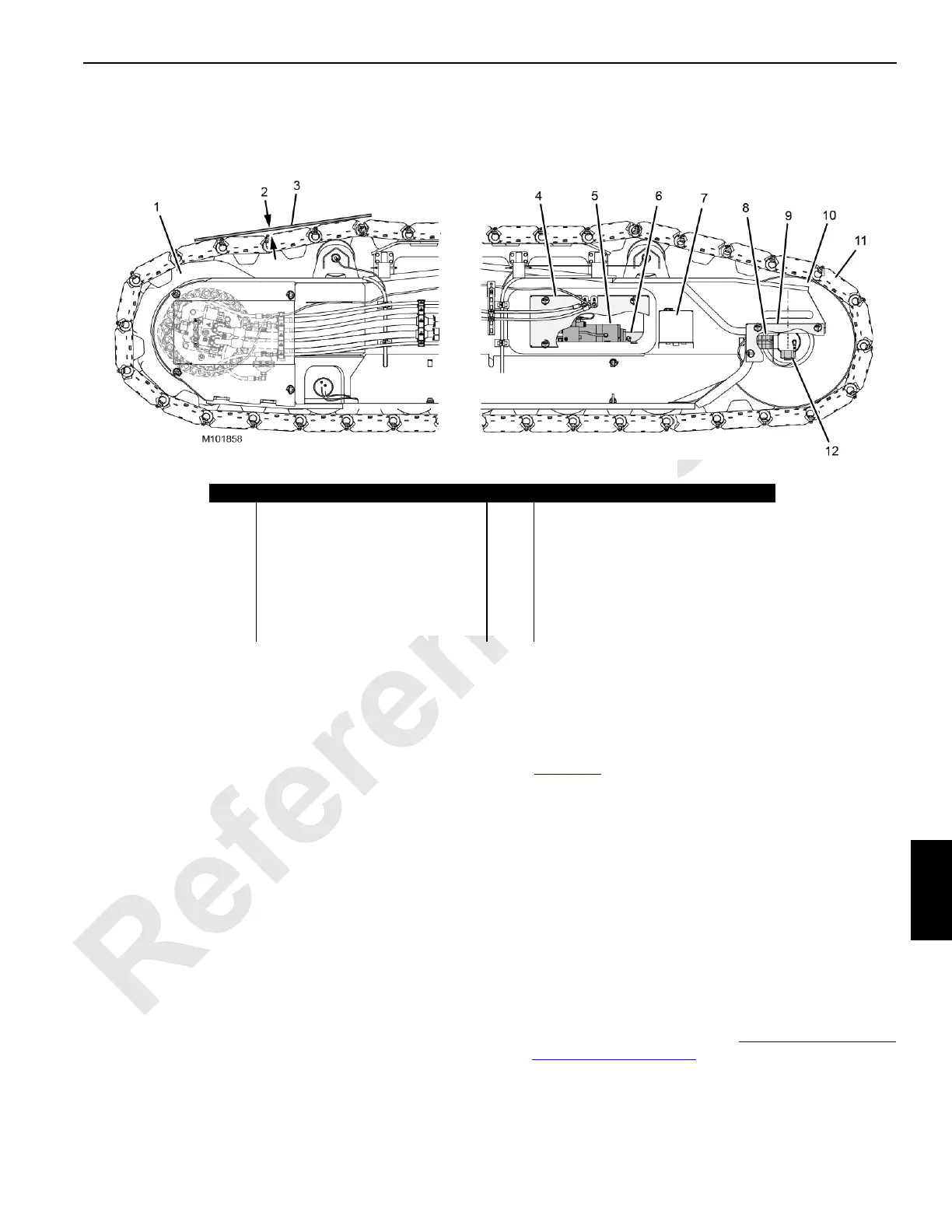

See Figure 8-9 for the following procedure.

Check tread slack (2) at the drive tumbler (1) end of each

crawler. Maintain equal tread slack at both crawlers.

1. Travel forward or reverse on a firm level surface until all

tread slack is in the top treads at the drive tumbler end of

the crawlers.

2. Place a straightedge (3) on top of the treads and

measure the tread slack between the straightedge and

the top of the tread at the lowest point.

• Tight limit gap—38,1 mm (1.5 in)

• Loose limit gap—76,2 mm (3.0 in)

3. If the slack exceeds the tight or loose limit, adjust

crawler tread slack (see Crawler Tread Slack

Adjustment on page 8-18.

FIGURE 8-9

Item Description Item Description

1 Drive Tumbler 7 Shim Storage Compartment

2 Tread Slack Dimension

• 38,1 mm (1.5 in)—Tight Limit

• 76,2mm (3.0 in)—Loose Limit

8Shim

• 12,7 mm (0.5 in)

• 25,4 mm (1.0 in)

3 Straightedge 9 Cover (qty 2)

4 Cover 10 Front Roller

5 Tensioning Cylinder 11 Tread

6 Rod 12 Nut and Bolt

Typical View Both Crawlers

Loading...

Loading...