Manitowoc Published 11-22-17, Control # 257-02 5-47

MLC300 SERVICE/MAINTENANCE MANUAL HOISTS

Daily Inspection

Wire rope should be inspected in accordance with ANSI/

ASME B30.5 and OSHA 29 CFR 1926.1413. A running

record of the condition of each wire rope should be noted in

the equipment inspection log.

• Each work day, prior to crane work, visually inspect all

rope that can reasonably be expected to be used that

day. Check for obvious damage, including the following:

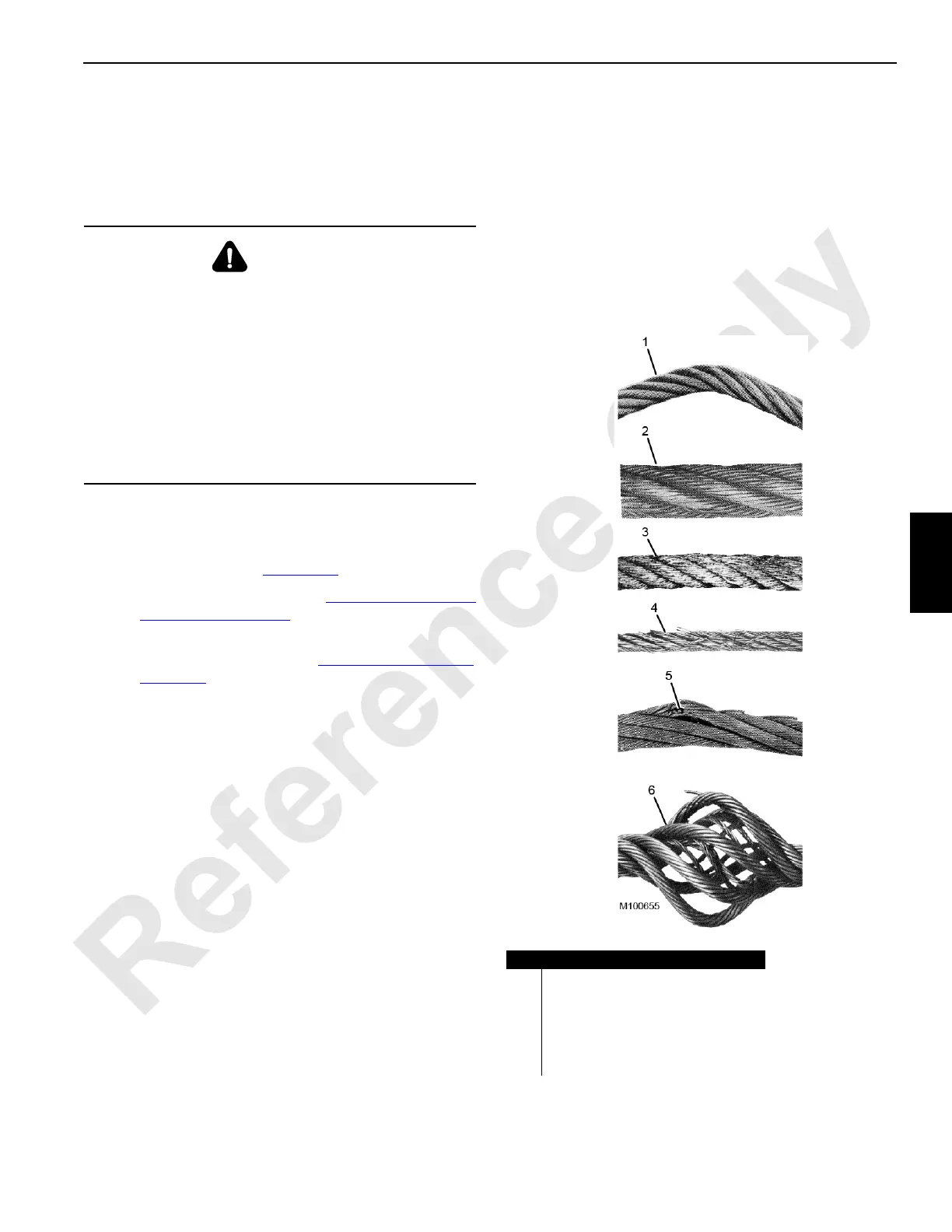

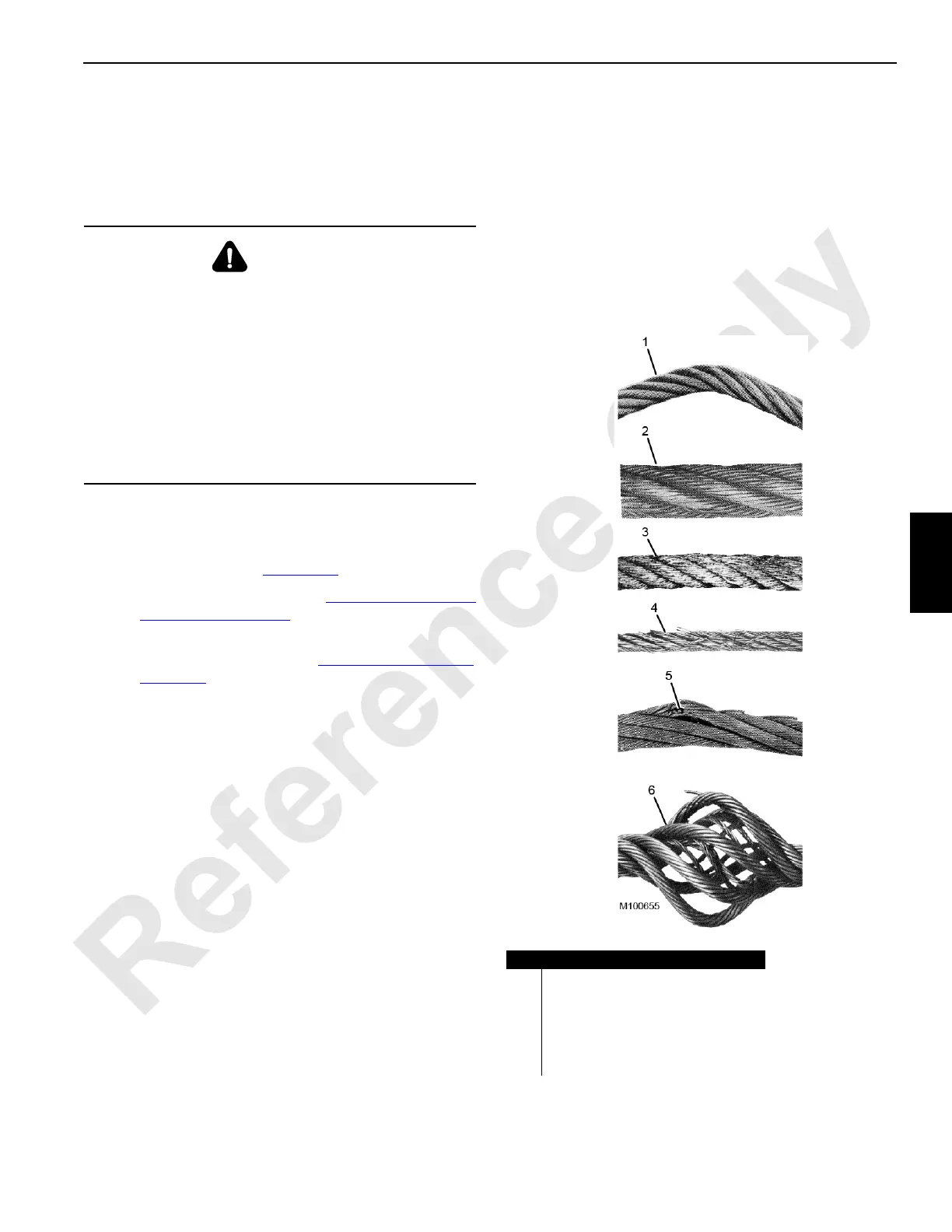

- Rope defects (see Figure 5-26

)

- Loss of rope diameter (see Reduction in the Rope

Diameter on page 5-48)

- Broken wires—Record the number, distribution, and

type of broken wires (see Broken Rope Wires on

page 5-49)

- Internal wear or broken wires for ropes operating on

synthetic sheaves. Common indicators of internal

deterioration include localized reduction in the rope

diameter, corrosion between the strands, localized

lengthening of lay, wire displacement, or wire

distortion.

- End fitting wear/abrasion

- Minor or general corrosion

- Areas that deteriorate more rapidly, such as the

flange points, the crossover points, and the

repetitive pickup points on the drums

- Take special care to observe the boom hoist ropes

and rotation-resistant ropes for evidence of core

failure or other deterioration (remove from service)

- Internal deterioration of rotation-resistant ropes may

not be readily observable

• Throughout the day, observe the wire rope during

operation, particularly the following:

- Pick-up Points—Sections of the wire rope that are

repeatedly stressed during each lift, such as the

sections that are in contact with the sheaves

- End Attachments—The point where a fitting is

attached to the wire rope or the point where the wire

rope is attached to the drum

- Abuse Points—The point where the wire rope is

subjected to abnormal scuffing and scraping

WARNING

Personal Injury Hazard!

Prior to conducting an inspection of wire rope:

• Lockout-tagout the crane when removing or installing

the wire rope assemblies.

• Use safety glasses for eye protection.

• Wear protective clothing, gloves, and safety shoes as

appropriate.

• Use supports and clamps to prevent uncontrolled

movement of the wire rope, parts, and equipment.

Item Description

1 Dog-Leg or Kink

2Drum Abrasion

3 Drum Crushing

4 Sheaves Too Small

5Corrosion

6 Bird Cage (sudden release of load)

FIGURE 5-26

Loading...

Loading...