McHale Fusion 3 Baler & Wrapper

81

3. Place spare knife in the working position and place a new spare knife

underneath, if available.

4. Tighten the two M6 setscrews to 12 Nm.

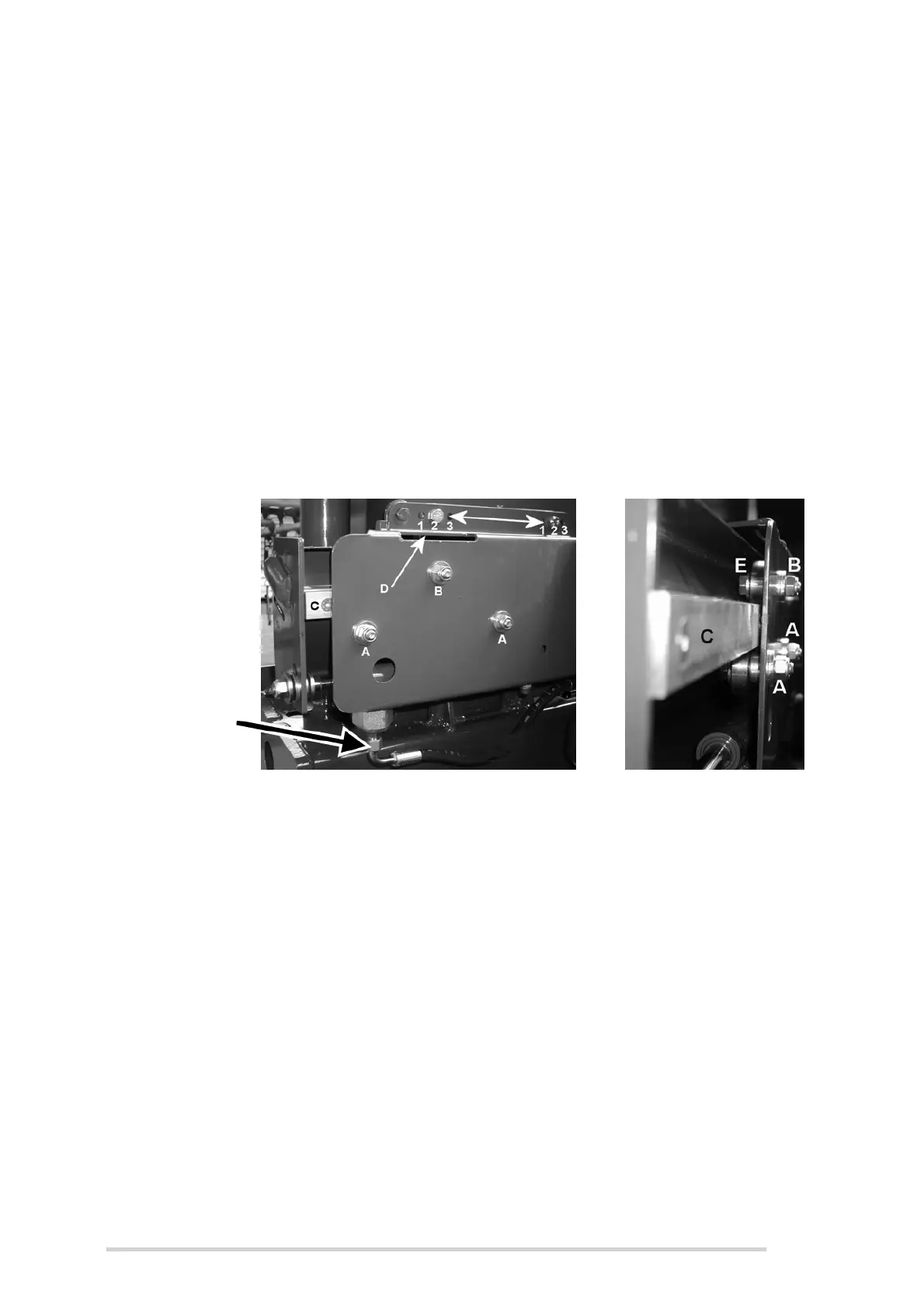

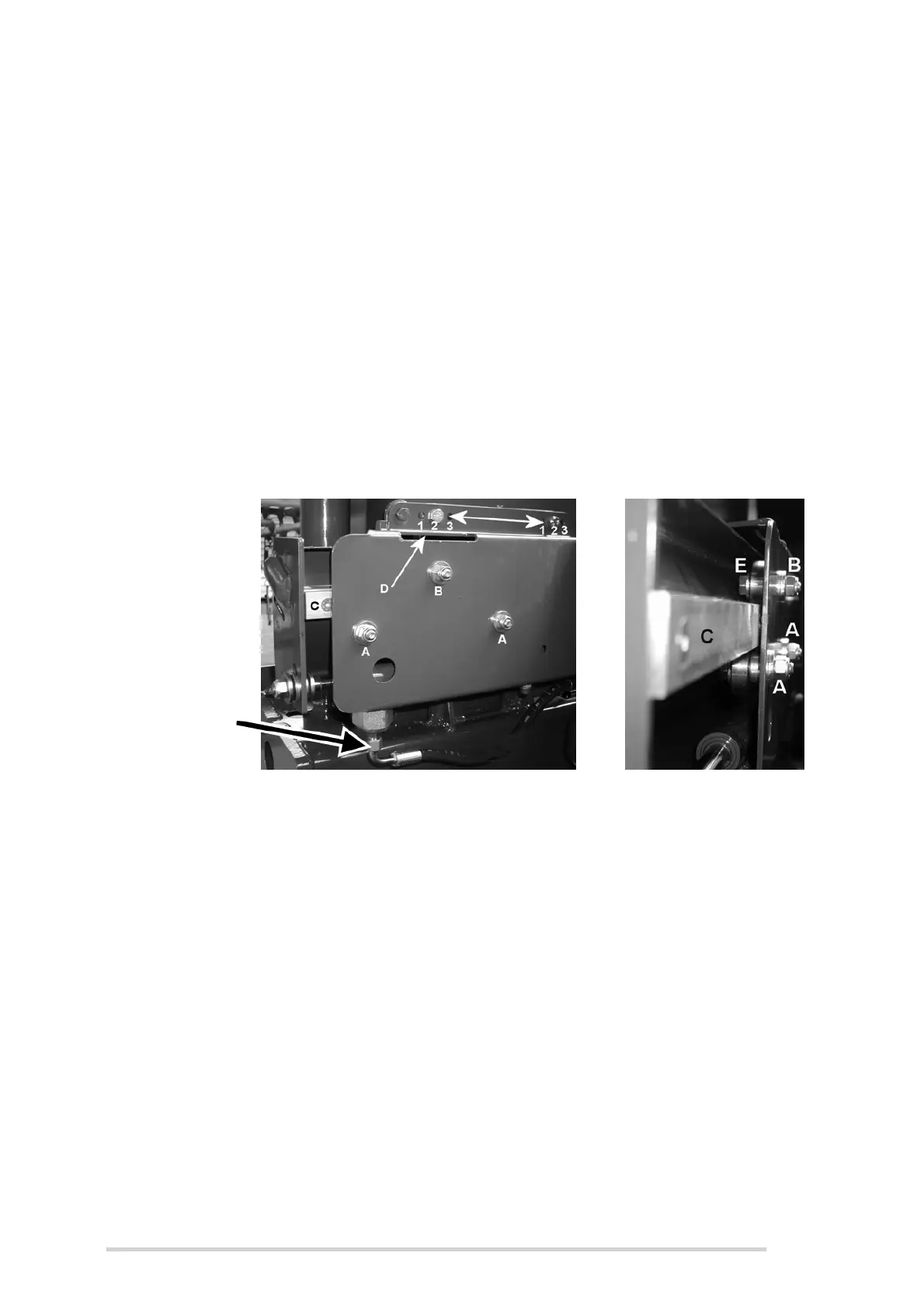

Cut and hold rail adjustment

After much use, the moving part of the cut and hold rail (C) may develop wear. In such

a case this may be adjusted, to ensure optimum working of the cut and hold. While

referring to Figure 8.l, adjust as follows:

1. Insert a 24 mm open ended spanner into slot (D) until it engages with the

hexagon on adjuster cam (E).

2. Loosen M12 nyloc nut (B) on adjuster slightly, just enough to be able to turn

adjuster (which works on a cam principle).

3. Turn adjuster (preferably clockwise from cam side E), with a 24 mm spanner,

until the resistance to turning increases greatly.

4. Hold resistive pressure on the adjuster cam (E) and tighten the M12 nyloc nut.

Figure 8.l - Cut and hold rail/horizontal position adjustment

Cut and hold horizontal position adjustment

The cut and hold assembly can be adjusted through three (3) different horizontal

positions, if desired. The factory set position is position 2 as shown in Figure 8.l. Ensure

that cut and hold assembly is safely secured (as assembly is quite heavy) before

attempting the following procedure:

1. Loosen and remove the four M12 x 40 mm bolts and 12 mm spacers and

carefully reposition bolts into the desired position i.e. 1, 2 or 3.

2. Place 12 mm spacers between cut and hold assembly and the main chassis,

then tighten M12 nyloc nuts to a torque value, as described in Section

“Tightening torque values” on page 108.

Accumulator

Pressure

Hose

Loading...

Loading...