www.roadwidener.com

26

Model SP-8 &10

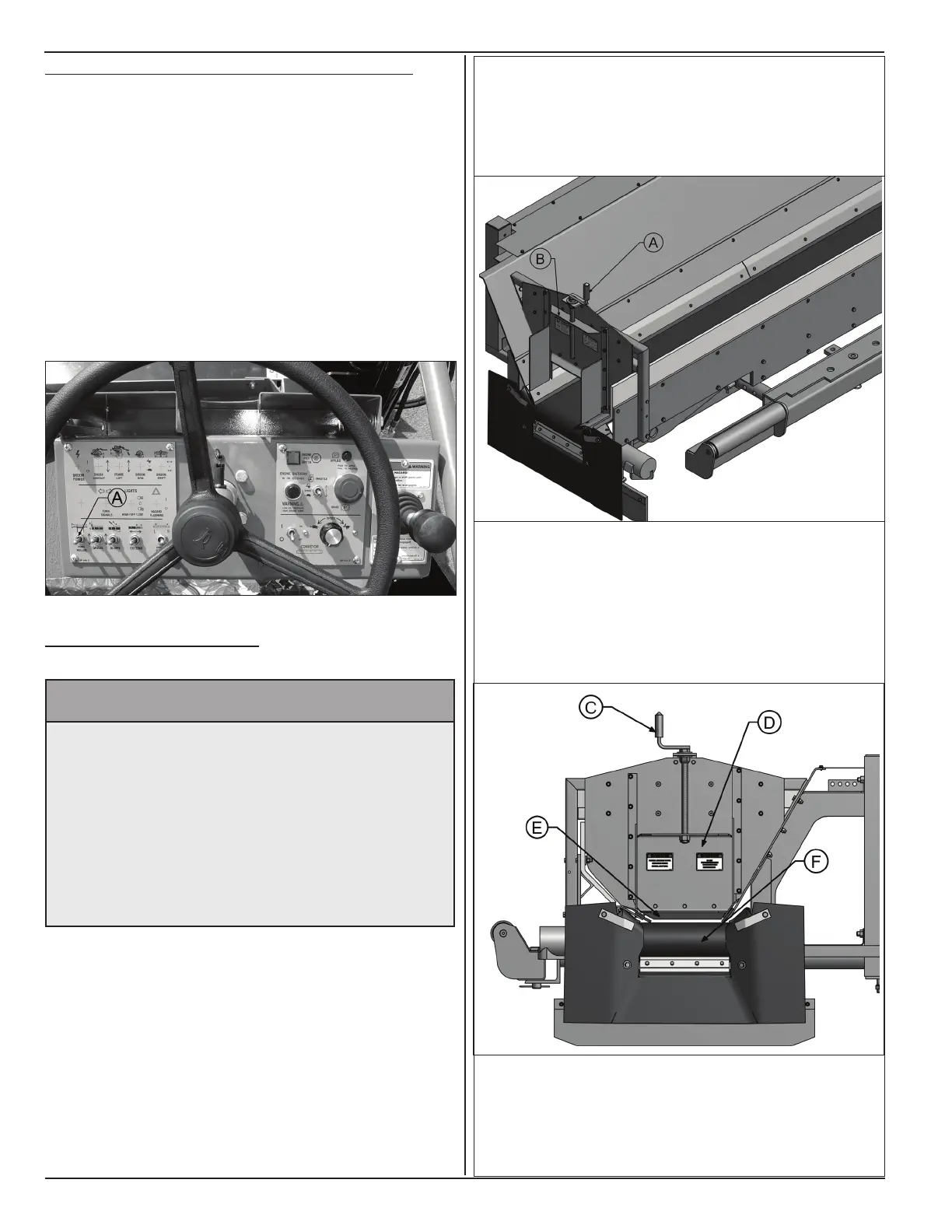

5.4.3 HydrAulIC pusH roller dIstAnCe setup

1. Start machine as in section 5.2.

2. Have dump truck back up towards hopper until truck

tailgate position is such that with tailgate locked

material should dump in center of the hopper ,

not on road or back of hopper. There should be a

minimum of 6 inch clearance above belt for tailgate.

3. Toggle push roller switch (A) to move push roller

beam forward until push rollers touch rear tires of

dump truck.

5.5 set Hopper GAtes

^ WARNING

Prevent serious injury or death.

Before performing inspections, service or

maintenance:

• Park machine on rm, level surface and

engage parking brake.

• Switch engine off.

• Close and lock control panel cover.

• Chock tires.

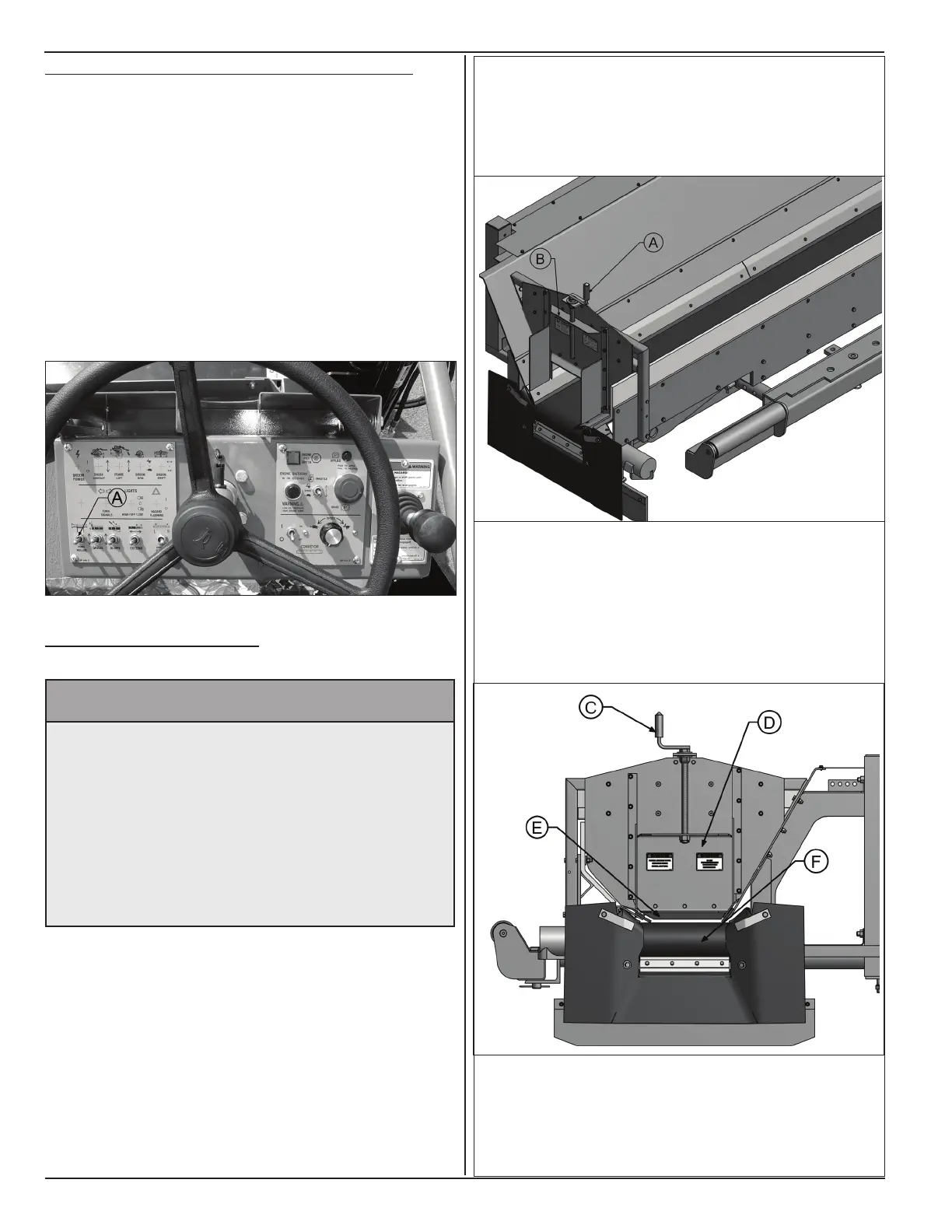

Procedure illustrated here is for dual sided machine

with optional end gate assemblies to control material

ow at discharge end. Instructions are same for single

sided machine with one end gate assembly.

1. Park machine on a rm level surface, engage

parking brake by pushing E-stop button operator

console fully down.

2. Switch engine off

3. Close and lock control panel cover.

4. Turn crank (A) clockwise on desired side of hopper

to lift gate (B) as high as required for sufcient

material ow.

5. On opposite end gate assembly in hopper, turn

crank (C) counterclockwise to lower gate (D).

6. Lower gate (D) until the gap between rubber seal

(E) and conveyor belt (F) is approximately 1/4 inch.

Loading...

Loading...