www.roadwidener.com

34

Model SP-8 &10

31. Apply lubrication to inside tubes welded to

moveable section for ease of operation.

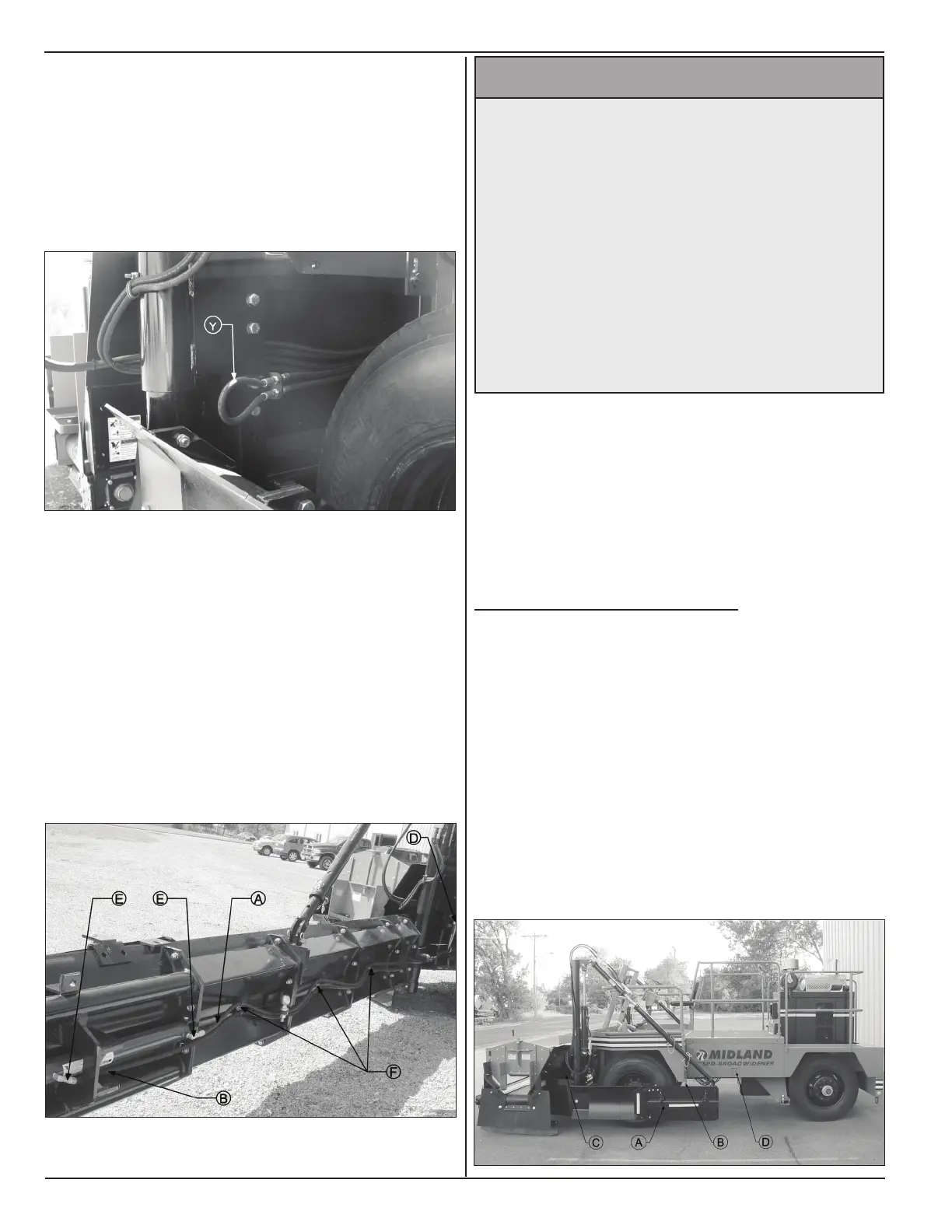

32. Remove loop hose (Y) from left side bulkhead

ttings. Connect marked hoses (A) and (B) for

“extend” and “retract” ports on respective bulkhead

ttings. Hose ends with 90° bend connect to

bulkhead ttings.

33. On right side bulkhead ttings (D), remove cap

ttings and use loop hose (Y) to connect the

“extend” and “retract” ports.

34. On left side blade assembly, mount hoses (A) and

(B) to blade sections by mounting hose clamps to

welded studs (F). Leave enough hose length near

blade column to compensate for blade swing.

35. Connect marked hoses (A) and (B) to “extend”

and “retract” port ttings (E) on hydraulic extension

cylinder.

^ WARNING

Pressurized uids can penetrate the skin.

Hydraulic hoses can fail from age, damage

and exposure.

Do not search for hydraulic leaks without

body and face protection. A tiny, almost

invisible leak can penetrate the skin,

thereby requiring immediate medical

attention.

Use wood or cardboard to detect hydraulic

leaks, never use your hands.

36. Start machine.

37. Raise left side blade assembly and test hydraulic

extension by toggling extend button both ways

on operator console. Check for leaks at hose

connections between hydraulic extension and

bulkhead ttings.

5.8 loAdInG for trAnsport

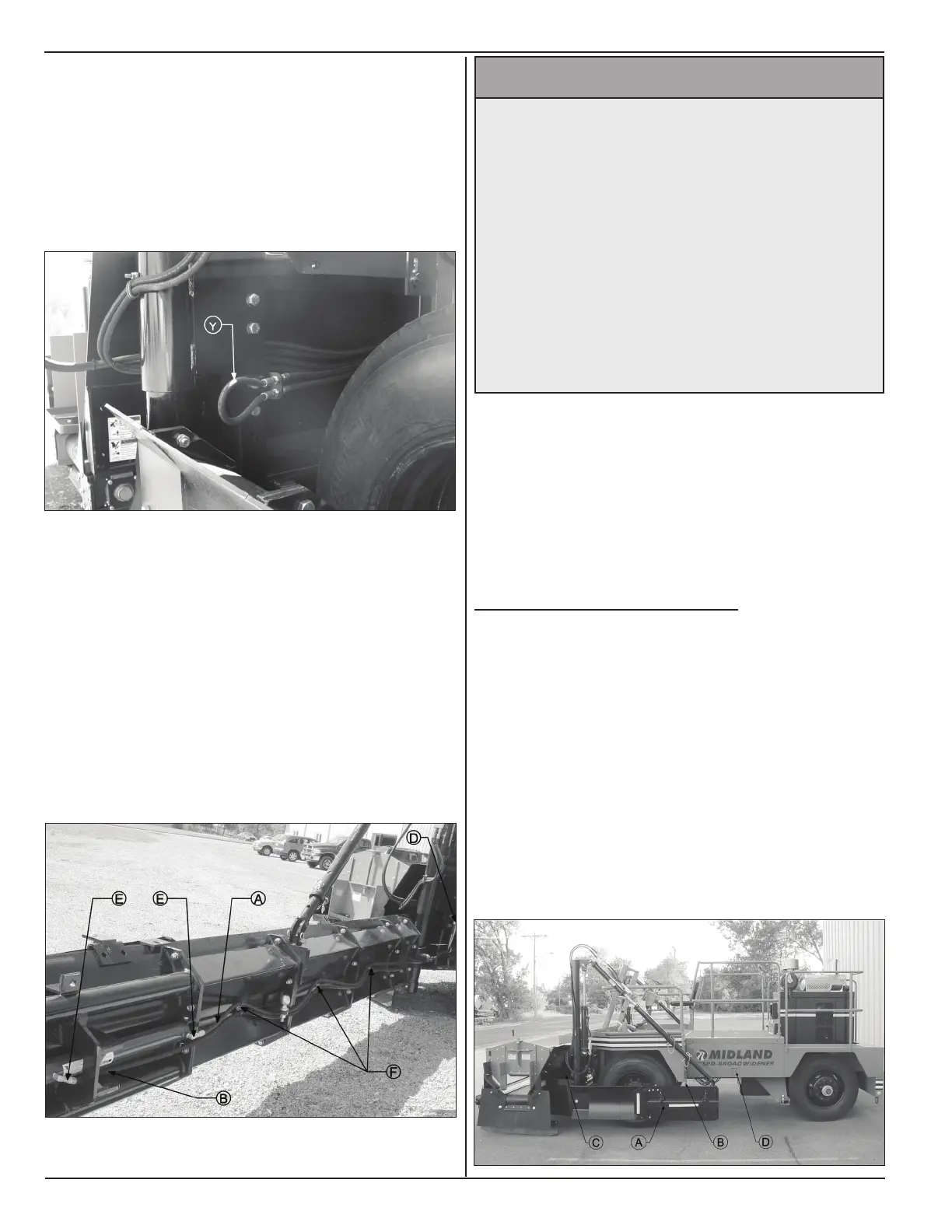

1. Conrm that both right and left side blade

assemblies (A) are folded and positioned parallel

to length of machine.

2. Conrm that both right and left side blade

assemblies are constrained to chassis by blade

constraint assemblies (B).

3. Store push tubes and outer edger brace in storage

area (C) and tie them to oor with cable ties.

4. Make sure that side access door (D) is secured

tight.

Loading...

Loading...