www.roadwidener.com

40

Model SP-8 &10

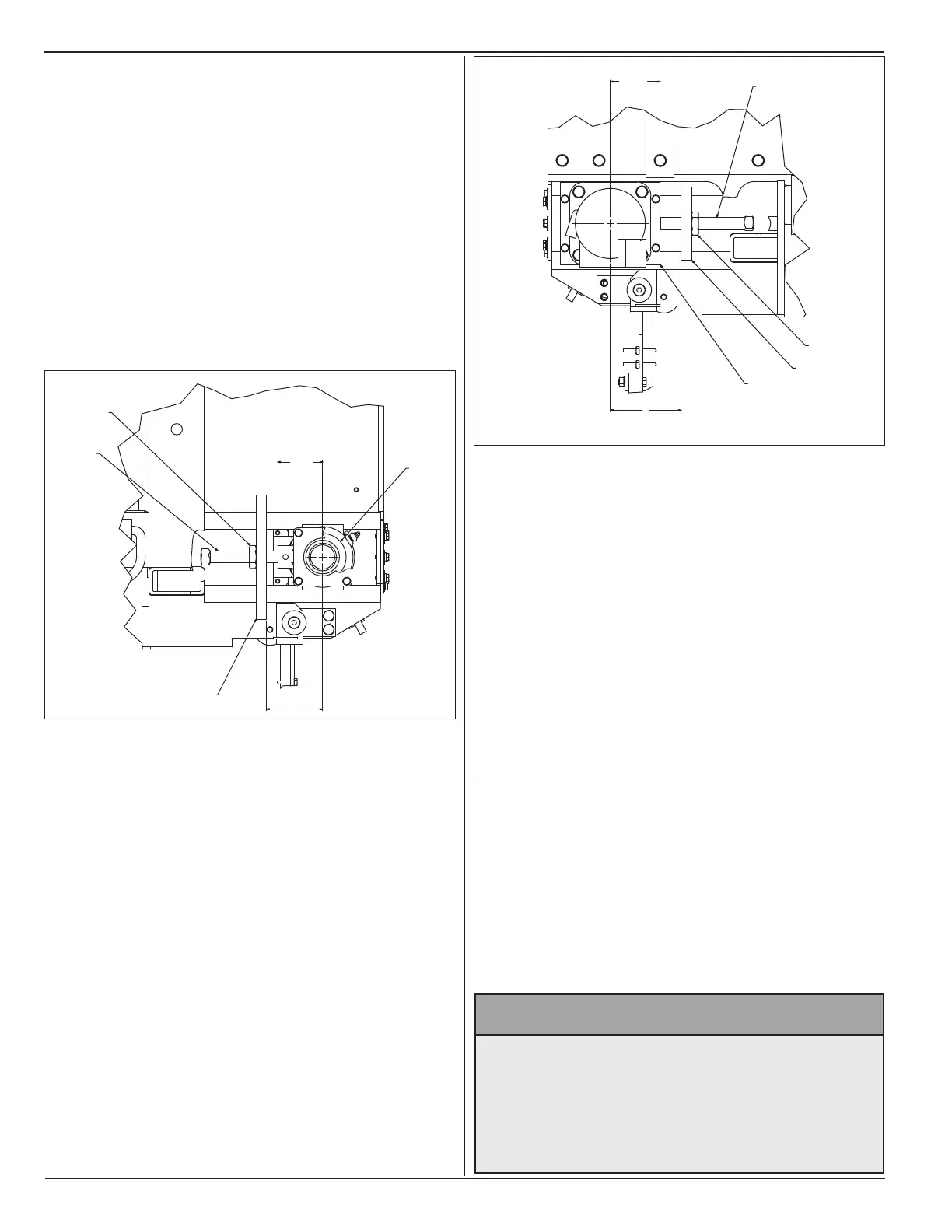

8. Loosen jam nuts (F) on all four square head cap

screws (G).

9. On hopper back side of both discharge ends,

measure distance “H” between mounting block (J)

and center of take-up bearing (K).

10. For conveyor belt to be centered left to right in

hopper frame, distance “H” must be same on both

discharge ends.

11. On hopper back side of both discharge ends, turn

square head cap screws (G) to make distance “H”

same.

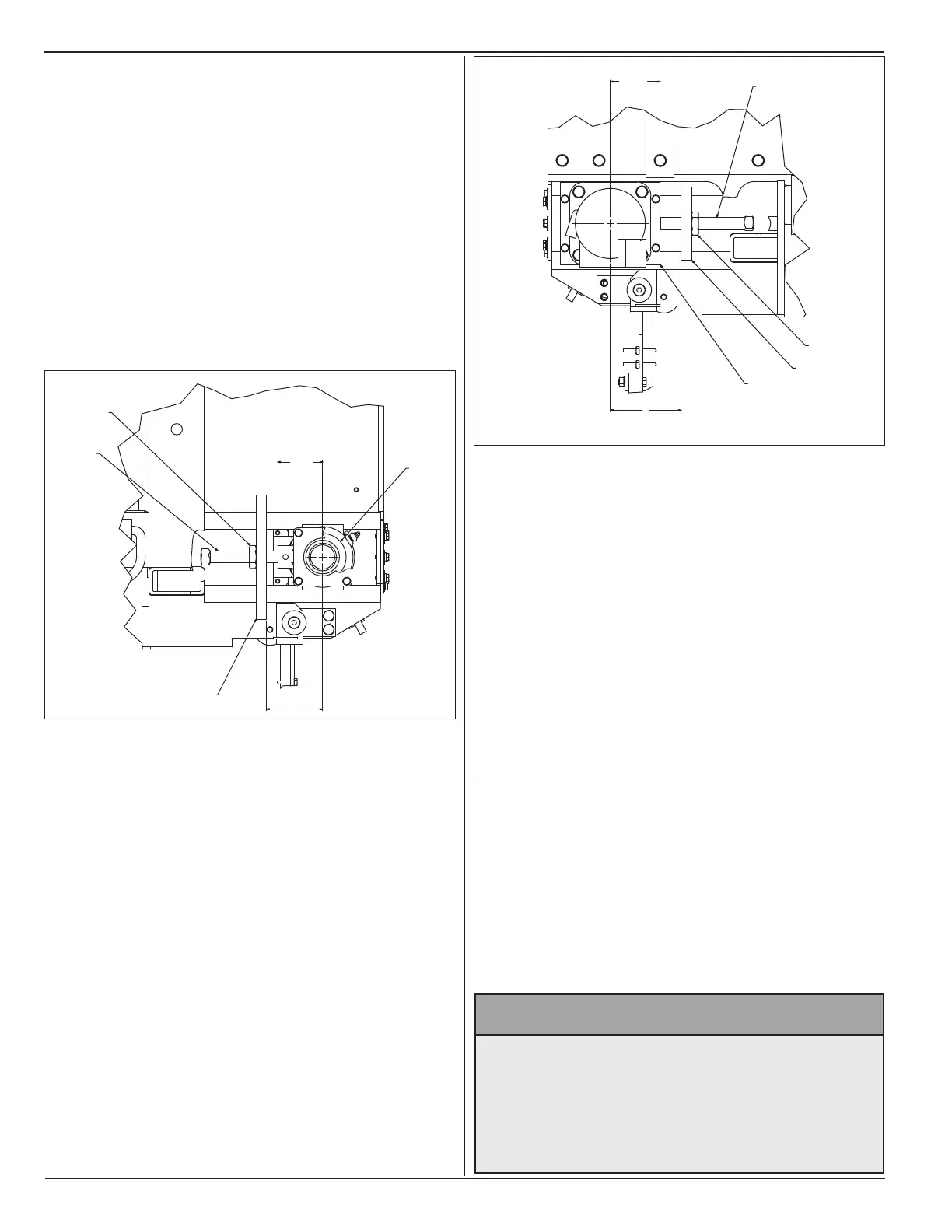

12. On hopper front side of both discharge ends,

measure distance “L” between mounting block (M)

and center of motor mount (N). On non-discharge

end of single sided machine, “L” is the distance

between mounting block “M” and center of take-up

bearing.

13. On hopper front side of both discharge ends, turn

square head cap screws (G) to make distance “L”

same.

14. On each discharge end, formula for correct

alignment of drive roller with the conveyor belt is

L = H+1

15. Adjust square head cap screws (G) to obtain

distance “L” and “H” as in step 14.

3 1/4

REF

H

F

G

J

K

HOPPER BACK SIDE

16. Turn four square head cap screws (G) equally to

move drive rollers outward.

17. Check conveyor belt tension by measuring distance

“A” as in step 1 and running belt as in steps 3-6.

18. Tighten jam nuts (F) against all mounting blocks.

19. On non-discharge end, re-install bib assembly on

dual sided machine. On single sided machine re-

install end plate.

6.3.2 replACe Conveyor Belt

Following section illustrates steps involved in

replacement of conveyor belt on SP-8 & 10 machines.

These steps should be followed to replace belt if wear

is visible on belt, or there is visible wear of splice hinge.

It is required that suitable lifting equipment is available

to lift and move hopper components. An overhead

crane use is recommended.

^ WARNING

Prevent serious injury or death.

Conveyor Belt and end gates are heavy.

Use an adequate lifting device to raise, lift

and move Conveyor belt and end gates.

3 9/16

REF

L

M

N

F

G

HOPPER FRONT SIDE

Loading...

Loading...