www.roadwidener.com

22

Model SP-8 &10

5.3.2 CHAnGe BlAde lenGtH

Procedure illustrates blade on right side. On dual side

machines, procedure is the same for left side blade.

^ WARNING

Prevent serious injury or death.

Before performing inspections, service or

maintenance:

• Park machine on rm, level surface and

engage parking brake.

• Switch engine off.

• Close and lock control panel cover.

• Chock tires.

^ WARNING

Prevent serious injury or death.

Blade components are heavy.

Use an adequate lifting device to raise, lift

and move blade and blade components.

Blade Pivot - 31 lbs.

1-Ft Blade Section - 57 lbs.

2 Ft Blade Section - 98 lbs.

Outer Edger Assembly - 113 lbs.

Hydraulic Extension Assembly - 225 lbs.

1. Start machine as in section 5.2. If machine is in

motion, park machine on a rm level surface,

engage parking brake by pushing E-stop button

fully down. Keep engine running at full rpm.

2. On dual side machine, toggle conveyor direction

switch to right side.

3. Lower blade to ground.

4. Switch engine off.

5. Close and lock control panel cover.

6. Remove pins (A) and remove push tube (B) from

blade.

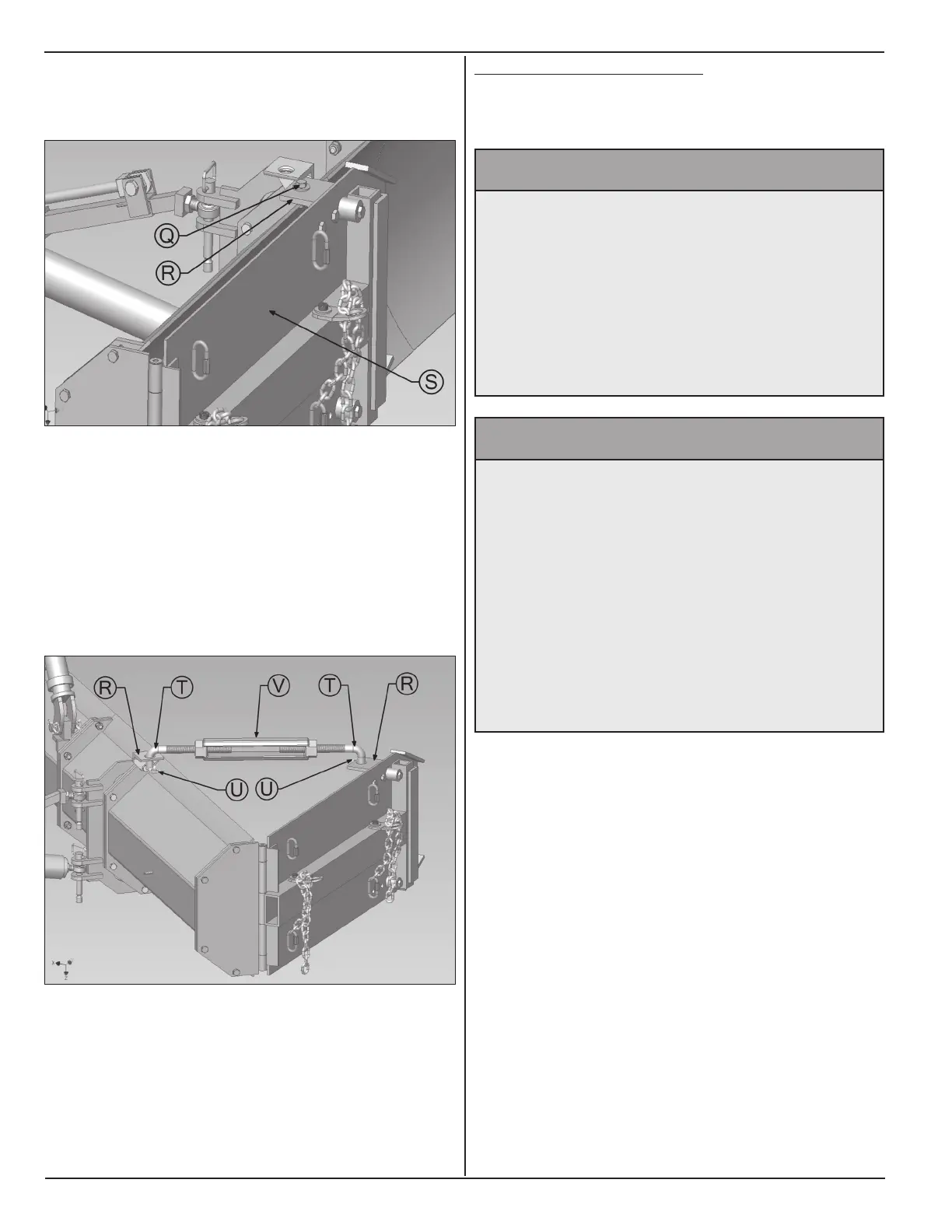

15. Remove locking hardware (Q) from turnbuckle

mount (R) on outer edger assembly (S). Swing

outer edger assembly (S) out.

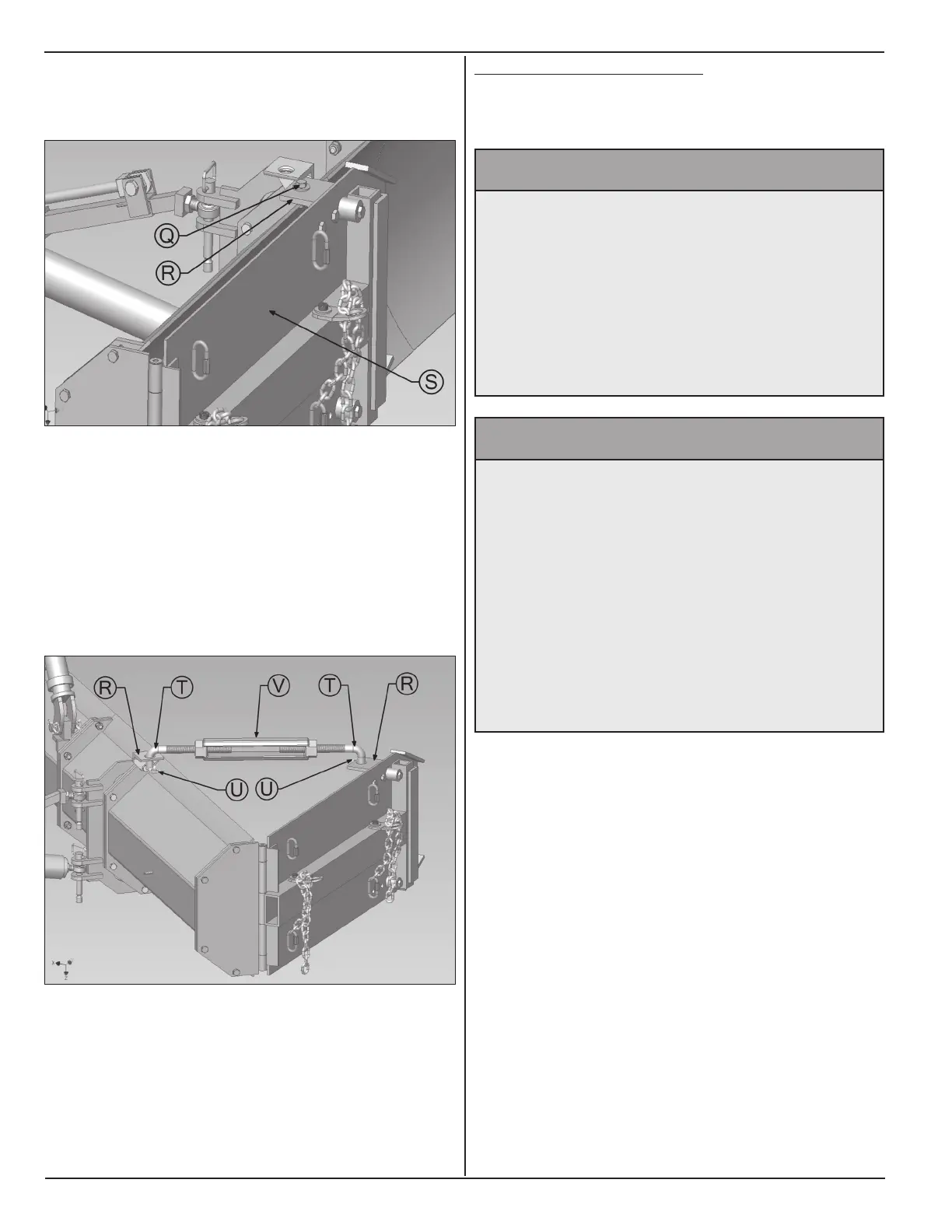

16. Retrieve outer edger brace from storage area.

Insert ends (T) of brace into turnbuckle mounts (R)

on outer edger and blade section.

17. Insert cotter pins (U) to secure outer edger brace.

18. Rotate turnbuckle (V) to adjust outer edger angle.

Outer edger should be parallel to blade assembly

inner edger.

19. Toggle slope and grade switches on operator

console to adjust slope angle and grade of blade

for desired shoulder prole.

Loading...

Loading...