www.roadwidener.com

46

Model SP-8 &10

When Sideboard Rubbers Are Left In Place

1. Adjust take up bearings evenly on both sides to

approximately. 30 lb/ft of torque.

2. Back off bolt 1/2 turn on both sides (approximately

1/16 inch).

3. Tighten jam nuts.

4. If torque wrench is not available, see section

“Adjust Conveyor Belt Tension” for steps to adjust

Belt tension

5. Sideboard rubbers must just touch belt. A gap will

allow asphalt to enter roller chain area. If sideboard

rubbers are pre-loaded against belt, rapid belt wear

will occur.

6.3.3.2 Adjust Scraper

Conveyor belt scraper is critical to belt wear. Scraper

mounts have rubber torsion springs inside so it will

spring out and back when splice comes around.

Scraper must be adjusted so that a sheet of paper just

slides between belt and scraper. However, if contact is

desired, adjust for absolute minimum contact pressure.

Scraper must be cleaned to remove accumulated

stones and grit at the end of each day while it is still

soft. This includes underside edge, which can act like

a cutting edge with stone buildup. The same is true

with the adjustable end gate seal.

6.3.3.3 Adjust End Gates

On discharge side, gate must be opened all the way. If

not, material ow is restricted and material slippage on

belt will increase. Material slippage on belt will result in

high belt wear.

6.3.3.4 End Of Day Clean Out

At the end of each day, inspect hopper and clean off

remaining paving material.

After asphalt usage, if a belt is left standing for a few

days, immediate start up will result in rapid belt wear. A

release agent prior to and after every use will lengthen

belt life.

Two recommended release agents are:

Zep slide (972) 228-3388

Tec shield (800) 700-2530

6.4 HydrAulIC system flusHInG proCedure

Whenever components such as, pumps, motors and

hoses are replaced on a closed loop system, the

loop must be ushed through a lter prior to start up.

Contamination due to previous component failure,

dirty assembly environment, and/or new hoses can

provide debris larger than maximum allowable size of

10 microns.

Whenever a pump or motor has failed, both pump and

motors in the loop must be replaced to eliminate source

of contamination. Pump and motors can be inspected

and rebuilt as necessary for reuse.

NOTICE

Prevent machine damage.

If a pump or motor failure has occurred.

Both pump and motors have to be replaced

to eliminate source of contamination.

Failure to do so can result in system

failure.

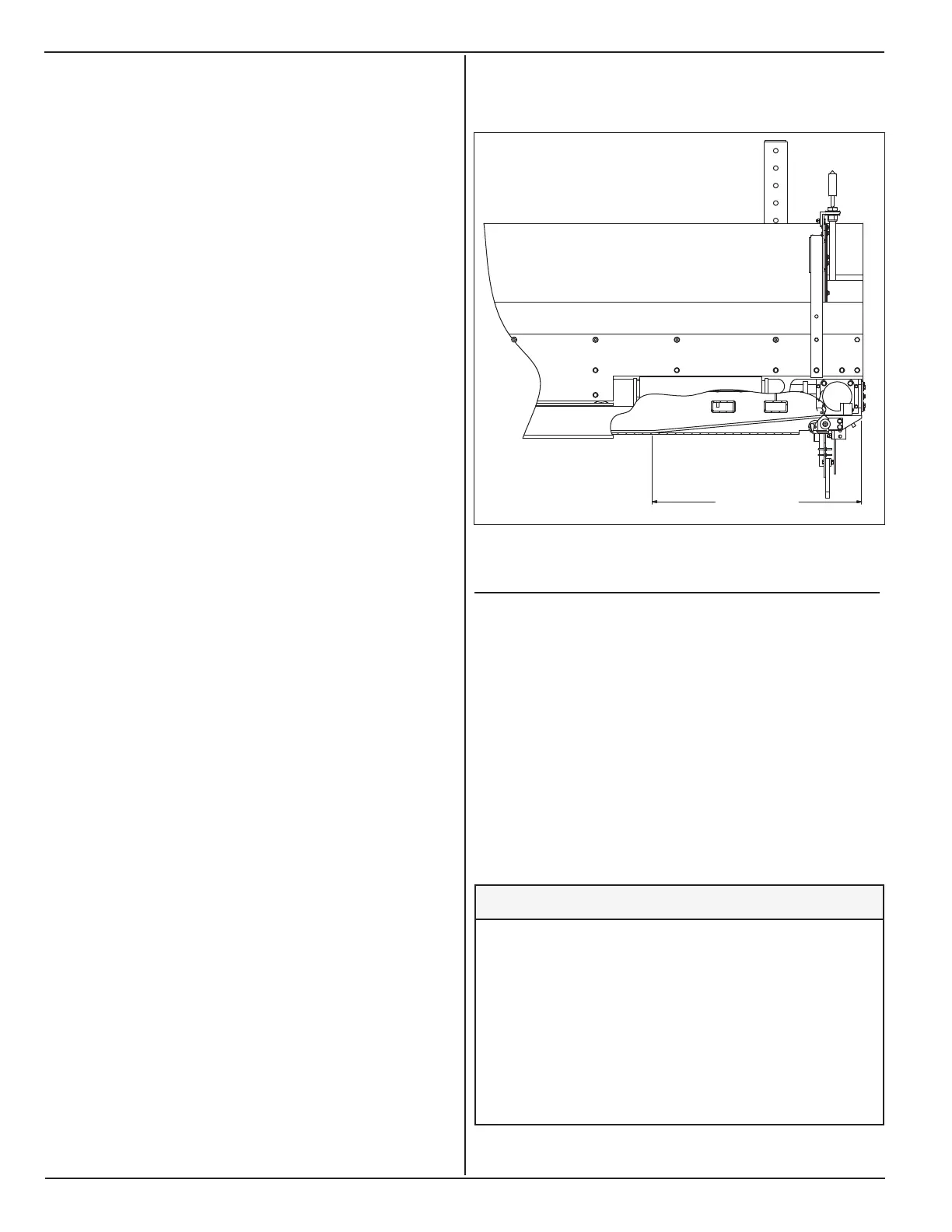

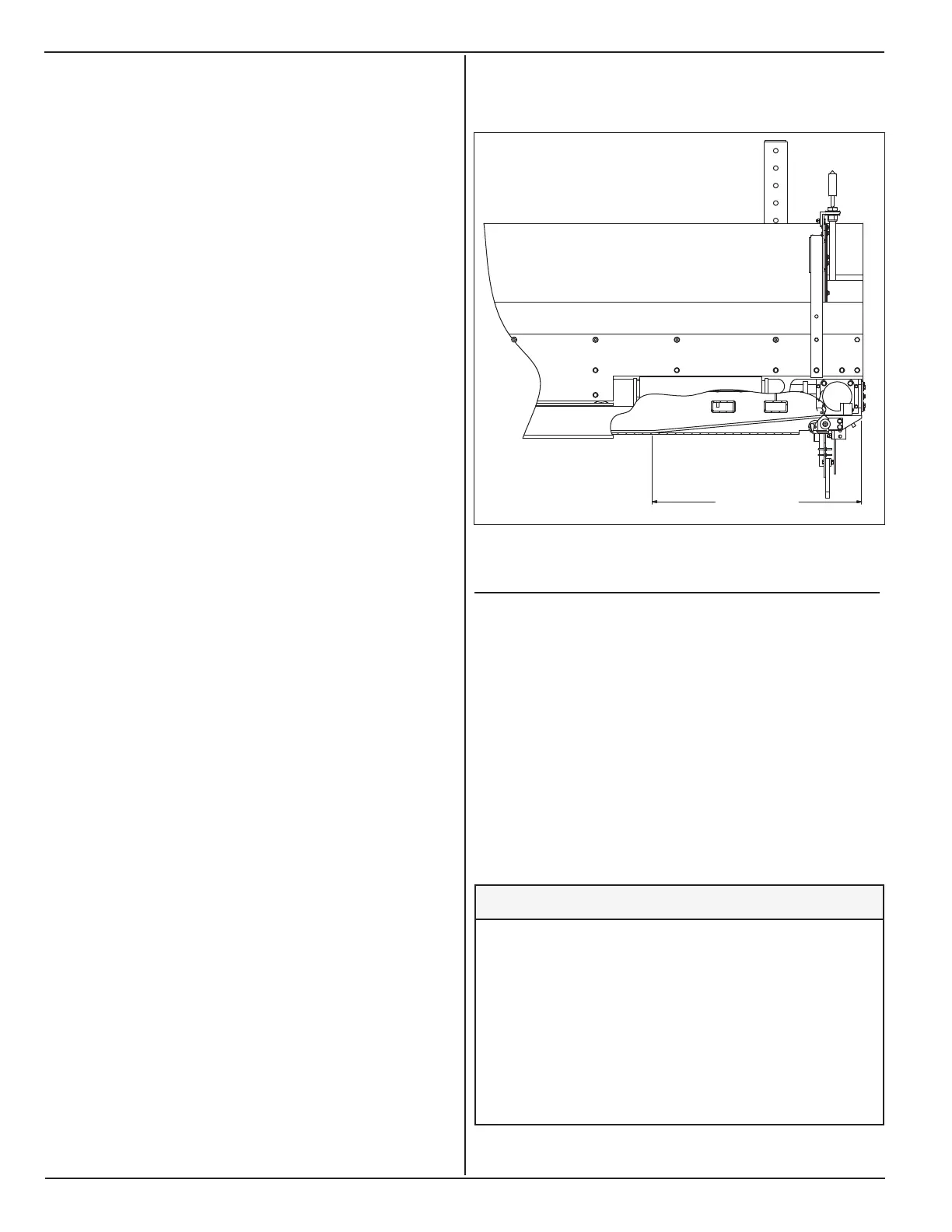

3635-

BELT ADJUSTMENT

INCHES

TO POINT OF

CONTACT WITH GUIDE

Loading...

Loading...