47

www.roadwidener.com

Model SP-8 & 10

NOTICE

Prevent machine damage.

Failure to perform ushing procedure after

a pump, motor or hose failure will result

in a repeat failure and will void machine

warranty.

Either the conveyor loop or traction drive loop can be

ushed, depending on which loop has failed. If there is

a concern that both loops have debris, refer to Flushing

Conveyor And Traction Drive Systems in section 6.4.3.

6.4.1 flusH Conveyor system

1. Drain and remove hydraulic tank.

2. Clean or replace both suction strainers and ush

out tank.

3. Install tank and replacement components.

NOTICE

Prevent machine damage.

Do not pour hydraulic oil directly into

closed loop circuit hoses or a failure will

occur.

In following detail, major steps are mentioned as “Step

#“ for dual side machine or as “Step #A“ for single

sided machine where applicable. These steps refer to

the schematic description with same headings.

step 1 or 1A

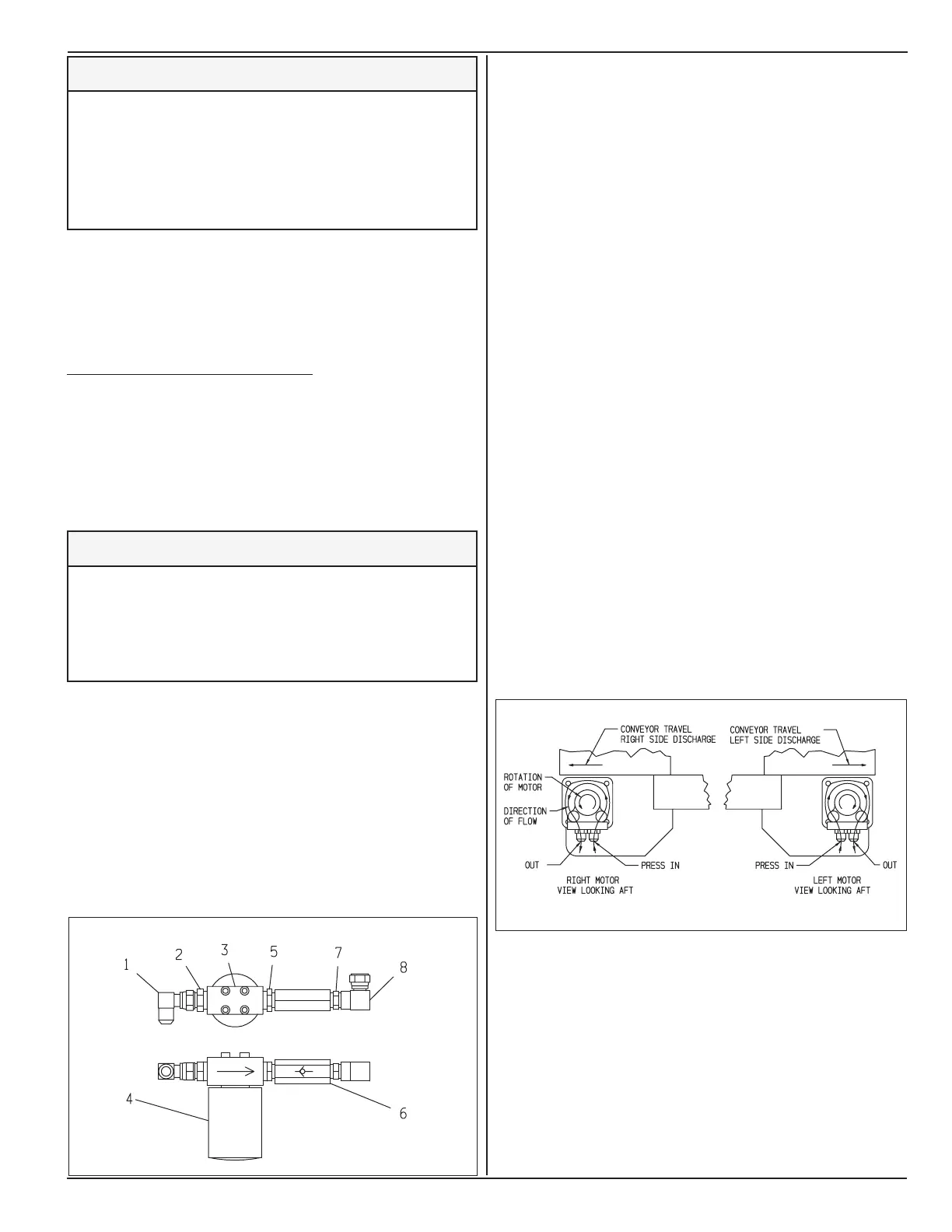

1. Assemble lter kit using dealer or customer supplied

components as shown below.

1 - 90° Elbow, 3/4 FNPT x FJIC Swivel

2 - Adapter, 1 MNPT x 3/4 MJIC

3 - Filter Head Donaldson #P166664

4 - Filter, Donaldson #P163555

5 - Adapter, 1 MNPT x 3/4 MNPT

6 - Check Valve, Danfoss #3C14-6-65

7 - Adapter, 3/4 MNPT x 3/4 MNPT

8 - 90° Elbow, 3/4 FNPT x FJIC Swivel

2. Install lter kit as shown in step 1 or step 1A

in schematics . Connect item #8 directly to pump

tting. Check valve prevents inadvertent back ow

or back ush into the loop.

3. If ow and pressure values are required for a new

pump installation, set up ow meter, valve and

gauge in loop prior to ushing. This will insure that

ow meter and gauges do not introduce debris after

ushing.

step 2 or 2A

1. On operator’s console, toggle conveyor direction

switch for right side discharge and turn off ow

control. Right and left side is dened as relative to

operator in seat.

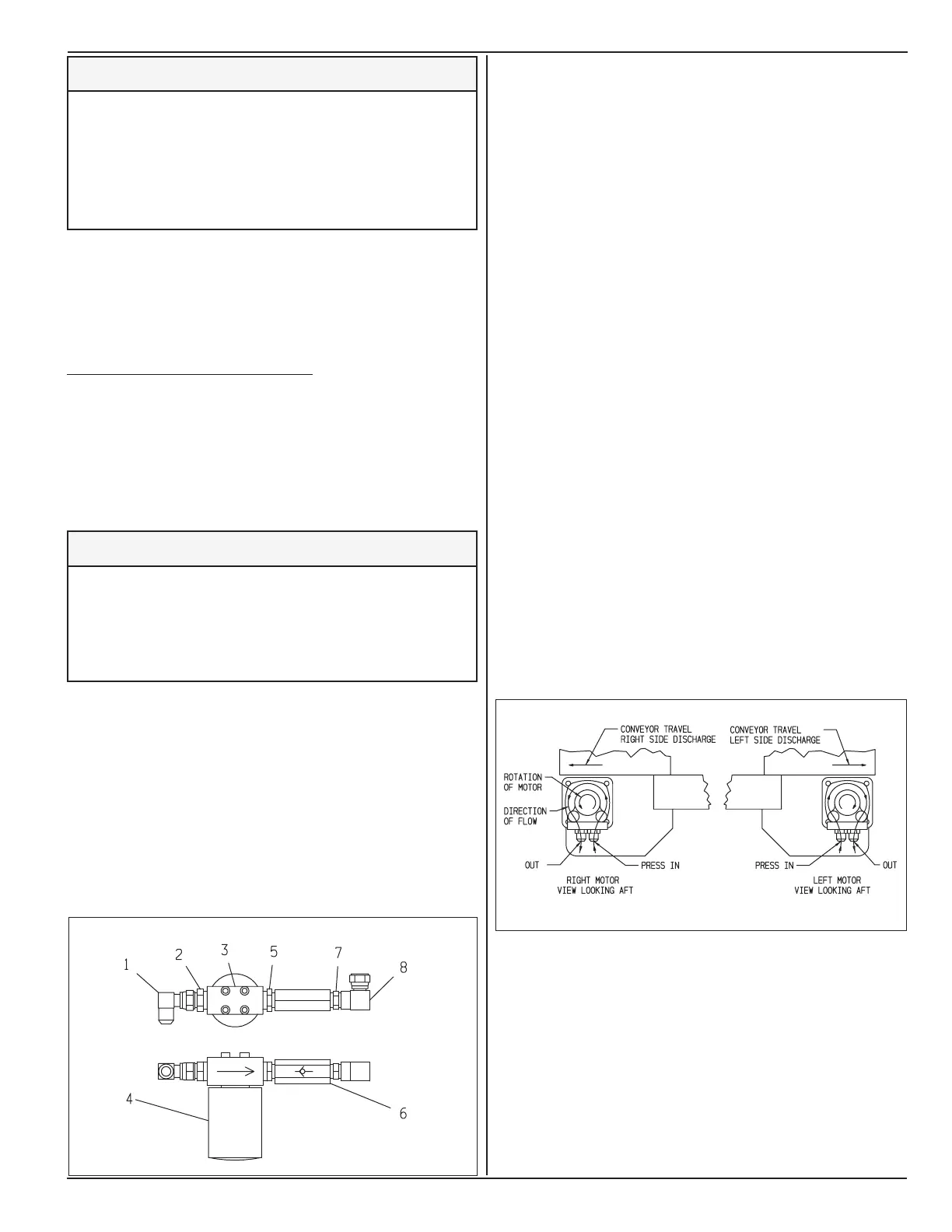

2. Follow pressure hose back from right side motor

to pump. This should be port “C” on pump. Verify

motor rotation and hoses as follows:

3. Label and disconnect two hoses at each motor and

connect to each other using a 3/4 MJIC x 3/4 MJIC

adapter. This is shown as step 2 (for dual side) and

2A (for single sided).

4. Start the engine and slowly increase conveyor ow

until lter’s “visual service indicator” is positioned

in center of the window. If pump goes over relief,

the ow is going against check valve. Stop the

ow, then reverse conveyor direction or hoses.

Loading...

Loading...