OM-244 814 Page 50

General Terms:

TH (Trigger Hold) Trigger Hold allows the operator to feed wire without continuously pressing the gun trigger. In trigger

hold mode, momentarily press gun trigger, and wire will feed until gun trigger is momentarily pressed

again.

Time Indicates time values being set for timed functions (e.g. Preflow, Postflow which are only available in

the Arc On and Analog input or the Arc On and No Analog input modes).

TPS (Trigger Program Select) TPS allows the operator to select weld programs by using the gun trigger. In TPS mode, momentarily

pressing the gun trigger allows the operator to cycle through preselected weld programs up to a total

of 8 programs.

Trigger Control Selecting Trigger Control allows activating trigger functions such as DS, IGNR, TH, 4T, TDS, and

TPS.

Volts Preset voltage in MIG mode at idle, actual voltage while welding, and 3 seconds hold value at end of

weld.

Wire Type Selection of wire type by alloys and classification.

WFS Term used to represent wire feed speed. In MIG mode, wire feed setting is independent of voltage

setting. In pulse and Accu-pulse adjusting wire feed speed also increases power level on wire elec-

trode (one knob control).

4T 4T allows the operator to select between weld parameters and crater parameters using the gun

trigger. Crater time must be set for at least 0.2 seconds to make this function operational. If gun

trigger is released during welding, unit goes into trigger hold, then pressing and holding trigger again

causes unit to stay in crater until trigger is released and crater parameter times out.

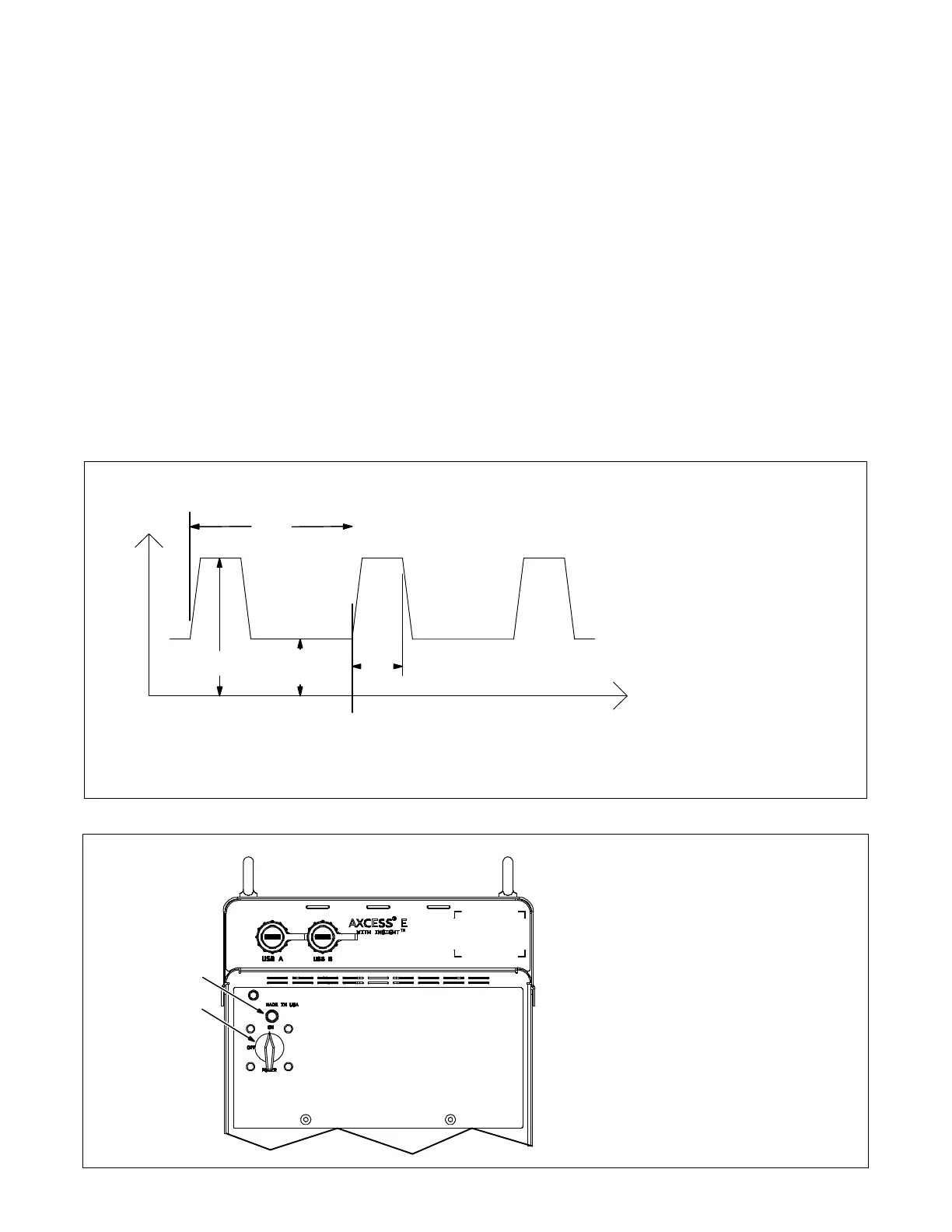

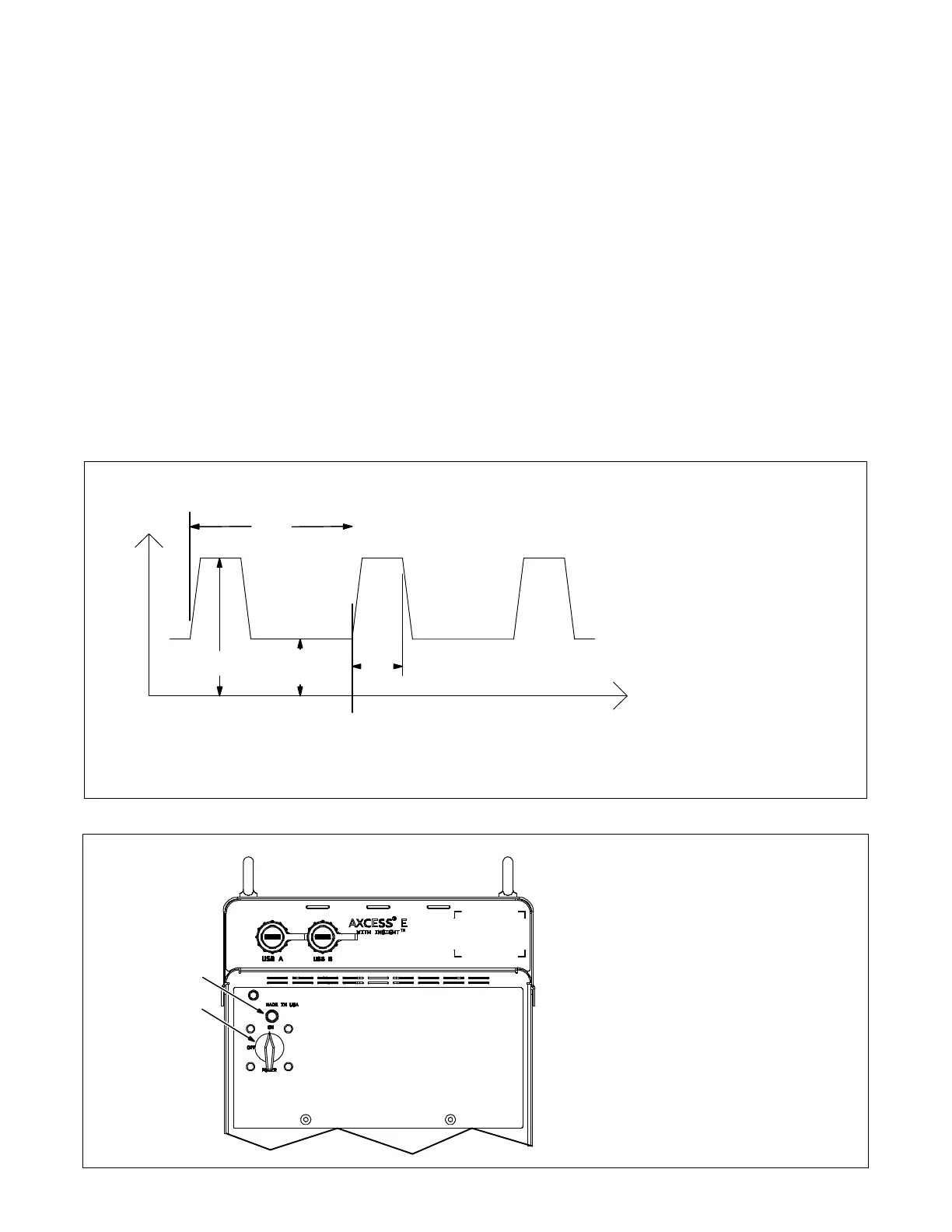

10-2. Pulse Welding Terms

1 Apk = Peak Amperage

Increasing Apk increases penetration.

Vpk = Peak Voltage

Arc voltage during peak current phase

of the pulse waveform. This determines

arc length during adaptive pulse

welding.

2 Abk = Background Amperage

Maintains arc between pulses.

Vbk = Background Voltage

Arc voltage during background current

phase of the pulse waveform. Stabilizes

weld puddle until next peak pulse.

3 PPS = Pulses Per Second

Increasing PPS increases travel

speed.

4 PWms = Pulse Width In

Milliseconds

Increasing PWms increases bead

width.

Time

Amps

3

1

2

4

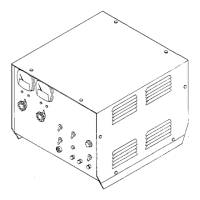

10-3. Front Panel Switches

Ref. 245 746-A

1 Power Switch

Turns unit On or Off.

2 Pilot Light

Light indicates status of welding power

source, on when unit is on and off when

unit is off.

1

2

Loading...

Loading...