A5/A3™ Service Manual 046-001141-00 2 - 35

Installation Guide Functional Tests

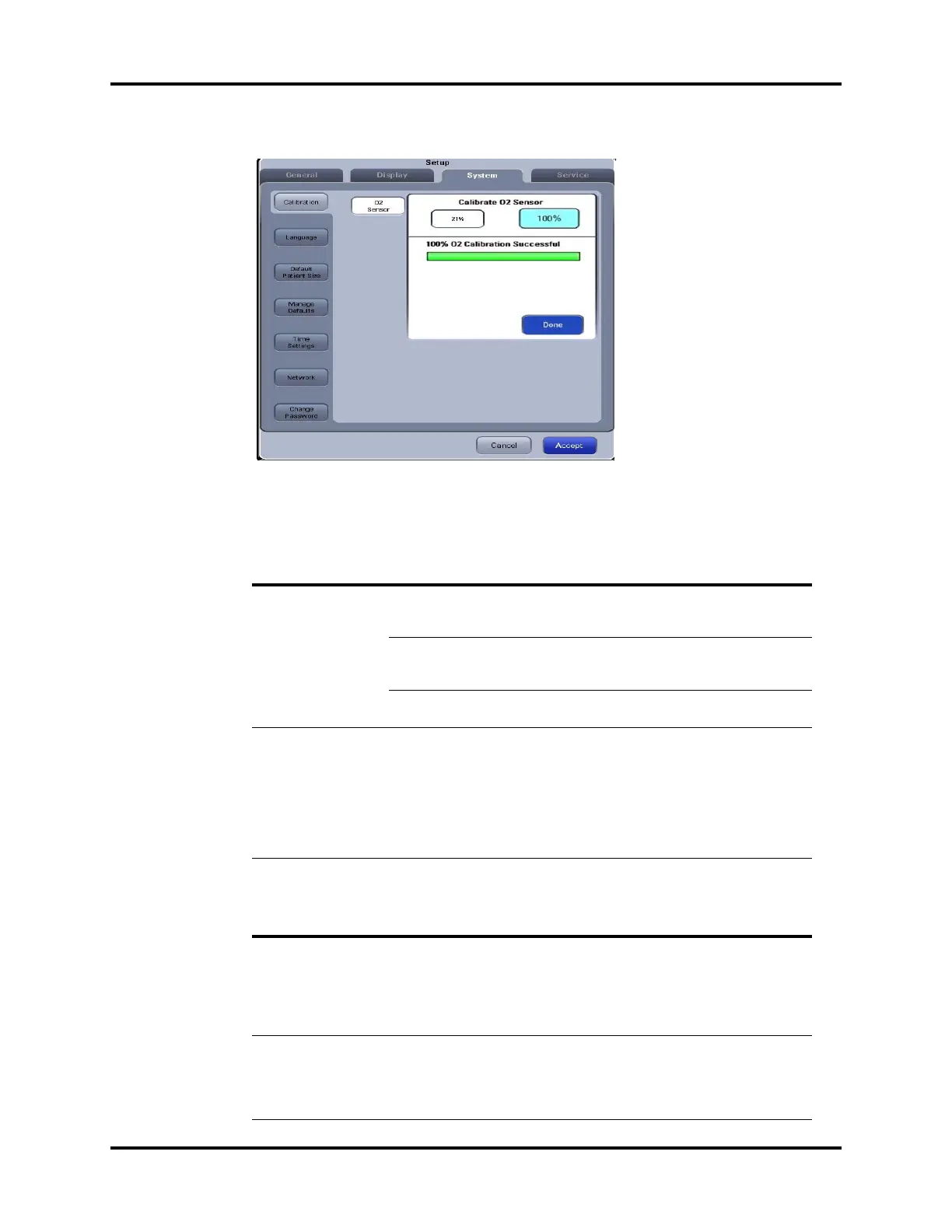

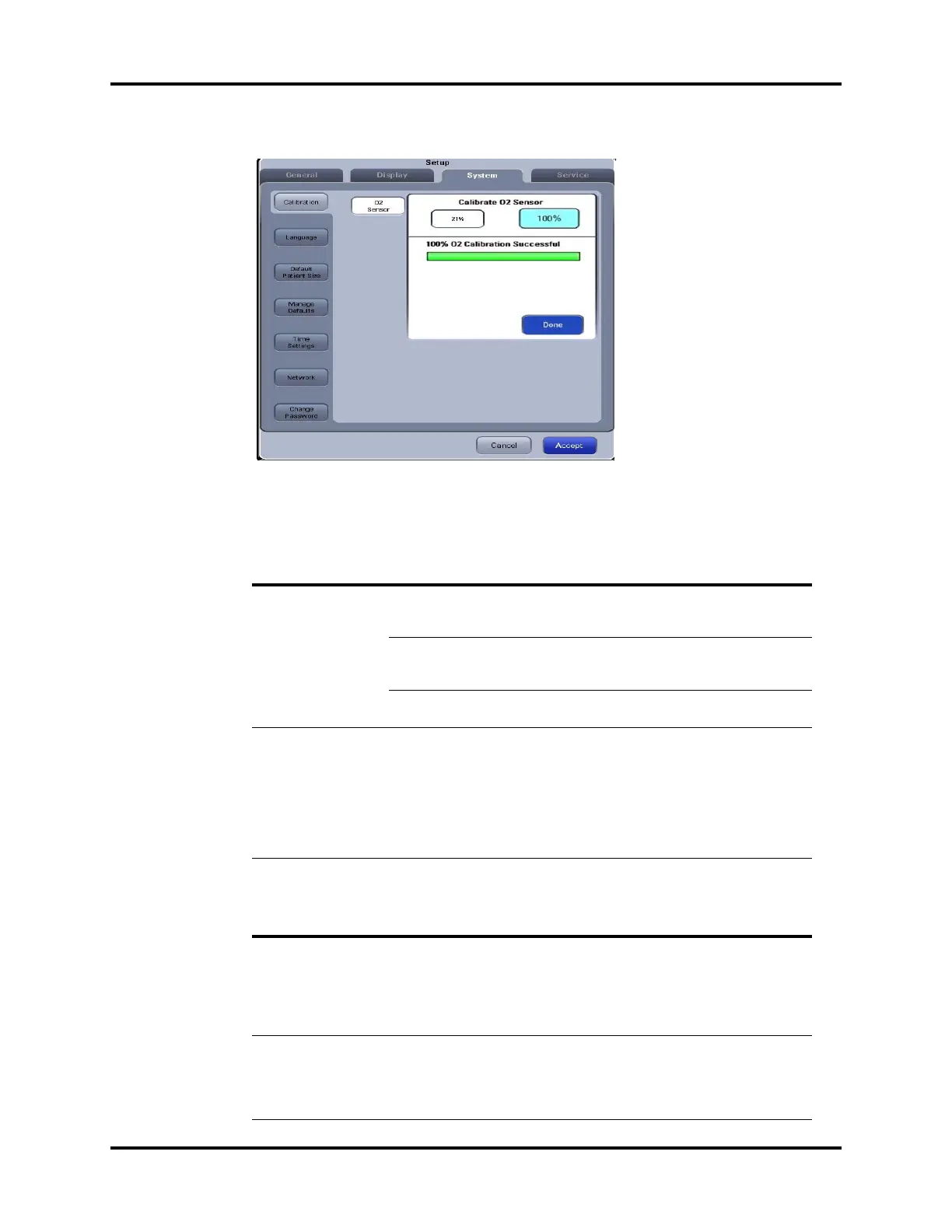

FIGURE 2-51 100% O2 Sensor Calibration Successful

2.3.3.3 Troubleshooting: O2 Sensor Calibration

Failure Description Possible Cause Recommended Action

After [Start] is selected,

calibration failure is

prompted very soon.

If the alarm [O2 Sensor Unconnected] is

displayed, it indicates that O2 sensor is

not connected.

Connect the O2 sensor.

O2 supply pressure is insufficient (lower

than 200 kPa).

Change or connect the gas supply

and make sure that O2 supply

pressure is sufficient.

21% O2 calibration is not completed

before 100% O2 calibration.

Perform 21% O2 calibration

followed by 100% O2 calibration.

Calibration failure is

prompted about 3

minutes after

calibration is started.

The O2% sampling value is not within the

normal range. Namely, the sampling value

of 21% O2 concentration is outside the

range of 150~500 and the sampling value

of 100% O2 concentration is outside the

range of 800~2028. Access Setup →

Service → Data Monitors → VCV to check

the O2% sampling value.

Replace the O2 sensor.

Error Code Description Recommended Action

00 00 00 02

O2 supply pressure is low.

During 100% calibration

process, O2 supply pressure

was not sufficient.

. Check that the O2 sensor is connected to the cable

correctly.

. Check the O2 supply pressure.

. Check that the O2 sensor output voltage in the calibration

menu is steady.

. Replace the O2 sensor.

00 00 00 04

O2 sensor is disconnected.

Sampled data is greater than

2900 (AD value).

. Check that the O2 sensor is connected to the cable

correctly.

. Check that the O2 sensor output voltage in the calibration

menu is steady.

. Replace the O2 sensor.

Loading...

Loading...