Pneumatic Circuit System Problems Repair and Troubleshooting

5 - 26 046-001141-00 A5/A3™ Service Manual

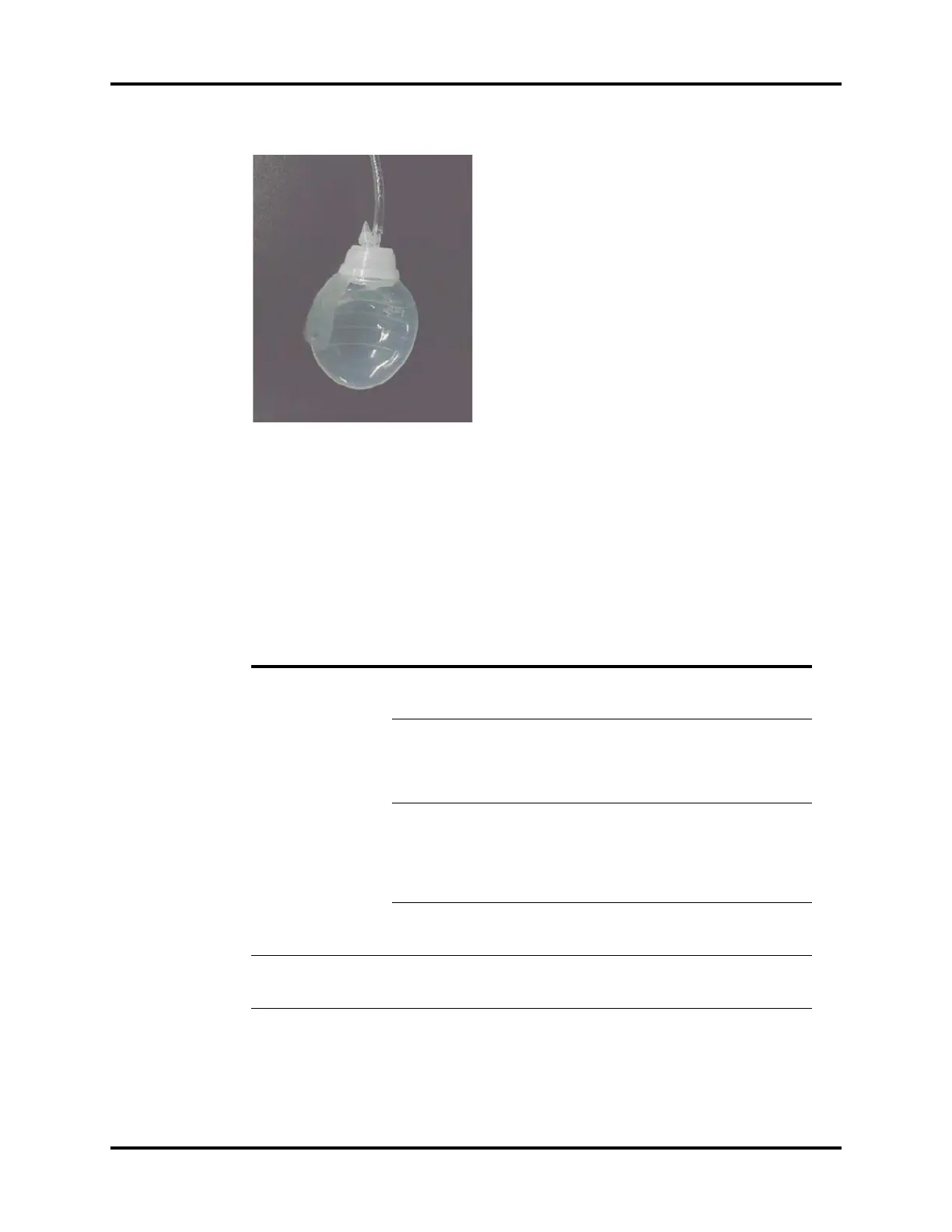

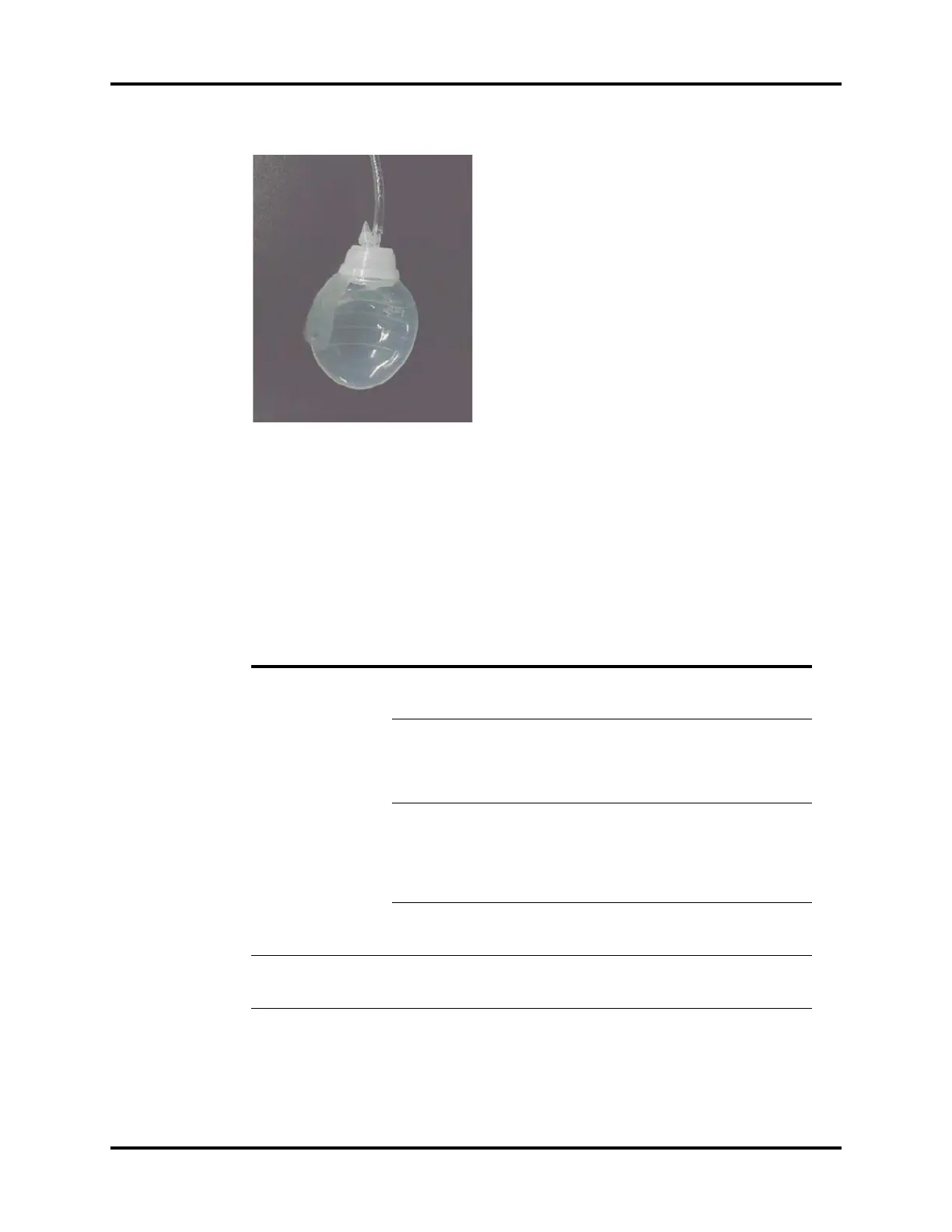

FIGURE 5-20

Before using the negative pressure ball, make sure that it is not leaky. Check if the front sealing cover

is tightened. Then flatten the negative pressure ball to remove the gas inside. Install the gas outlet

plug properly. Block the front gas inlet with your finger then release the ball. Ball should not visibly

inflate for at least 30 seconds. If it does, replace the ball.

5.3.2 Gas Supplies and Drive Gas

The following table lists gas supplies and drive gas related failures.

Failure description Possible cause Recommended action

Leak

The gas supply tube is

damaged or the seal at the

connection is damaged.

Replace the gas supply tube or the seal at the

connection.

The quick plug-in

connector leaks.

Replace the quick plug-in connector or PU tube

(when the PU tube is not damaged, if the tube is

long enough, cut off a small segment of the tube

where the quick plug-in connector is met, and

then insert the tube into position).

The pipeline gas supply

inlet assembly leaks.

Check if the check valve of the pipeline gas

supplies inlet assembly leaks in the reverse

direction. Replace it if necessary. Check and

replace the damaged seal of the pipeline gas

supplies inlet assembly. If the problem persists,

replace the pipeline gas supplies inlet assembly.

The drive gas pipeline

leaks.

Check and repair the expiratory valve assembly as

per the procedures described in ‘‘Leak Test of Low-

pressure Pneumatic Circuit System’’ on page 5-53,

Pipeline pressure gauge

shows inaccurate

readings or no readings.

The pipeline pressure

gauge is damaged.

Replace the pipeline pressure gauge.

Loading...

Loading...