Pneumatic Circuit System Problems Repair and Troubleshooting

5 - 64 046-001141-00 A5/A3™ Service Manual

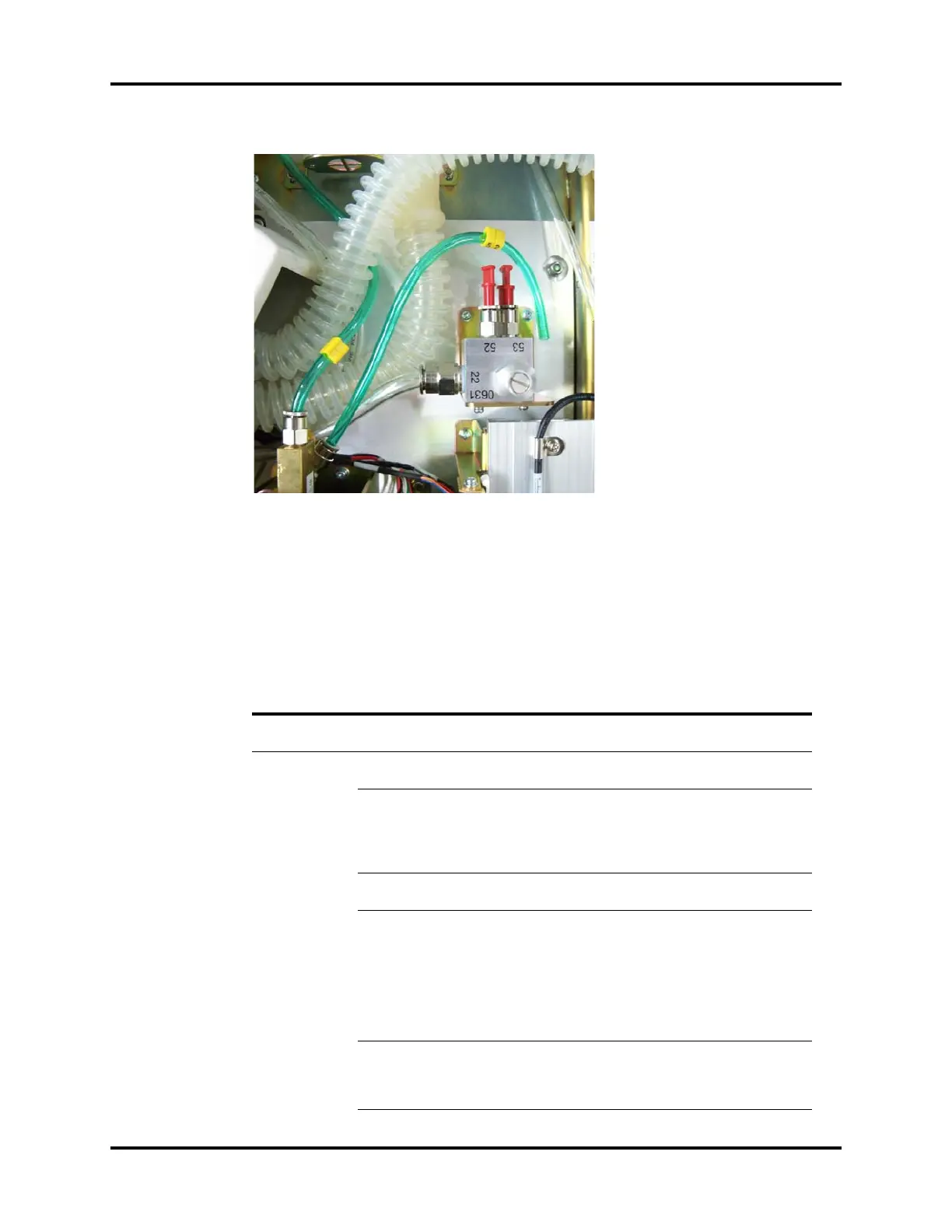

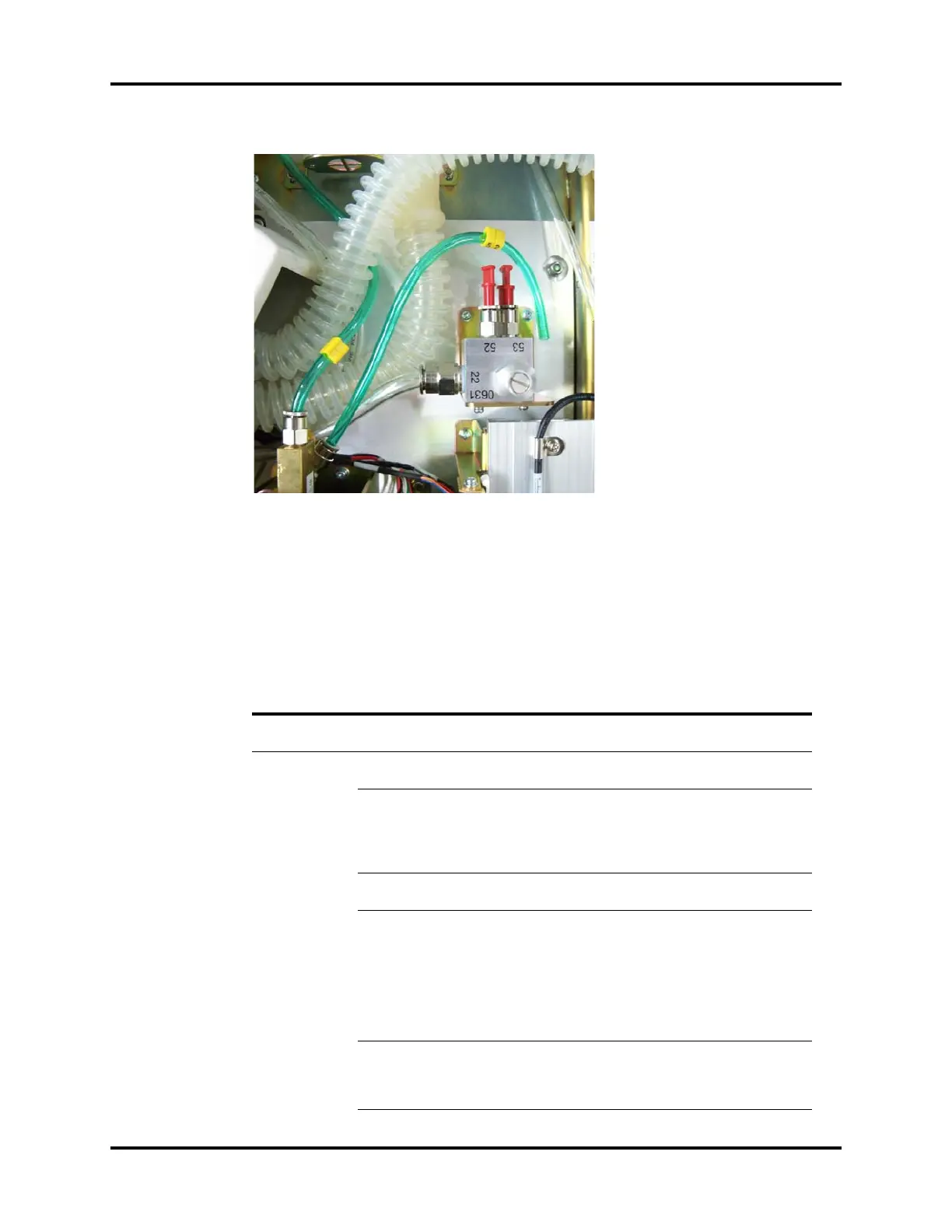

FIGURE 5-68

7. Repeat steps 3 through 7 in “4 Leak test of all pipelines on the circuit adapter”. If the test fails,

it indicates the CGO assembly is damaged. Check the seals in the CGO assembly and replace

any damaged seals.

5.3.5 Tidal Volume

The following table lists tidal volume inaccuracy related failures.

Failure

description Possible cause Recommended action

Inaccurate tidal

volume

The flow sensor is not installed properly. Re-install the flow sensor.

The setting of fresh gas flow is

inappropriate.

Adjust the fresh gas flow.

There are significant leaks in the

breathing system and the fresh gas flow

is too low.

Repair the leaking points after checking as

per the procedures described in

“Anesthetic Gas Delivery System” on

page 5-35. and “Breathing System” on

page 5-50.

* There is water build-up inside the flow

sensor.

Remove the flow sensor and clear its inside

water build-up.

*The membrane of the flow sensor

assembly is distorted, dirty or its inside

resistance changes. Zero drift occurs to

the pressure sensor on the ventilator

control board.

Enter the service mode and calibrate the

flow sensor as described in “If

measurement deviations are not corrected

after multiple flow sensor calibrations, the

user is recommended to replace the flow

sensor and then perform calibration. If the

problem persists, factory maintenance is

necessary.” on page 4-18..

*The flow sensor pressure sampling

pipeline is leaky.

Repair the leaking points after checking as

per the procedures described in “Leak Test

of Flow Sensor Pressure Sampling Pipeline”

on page 5-51..

Loading...

Loading...