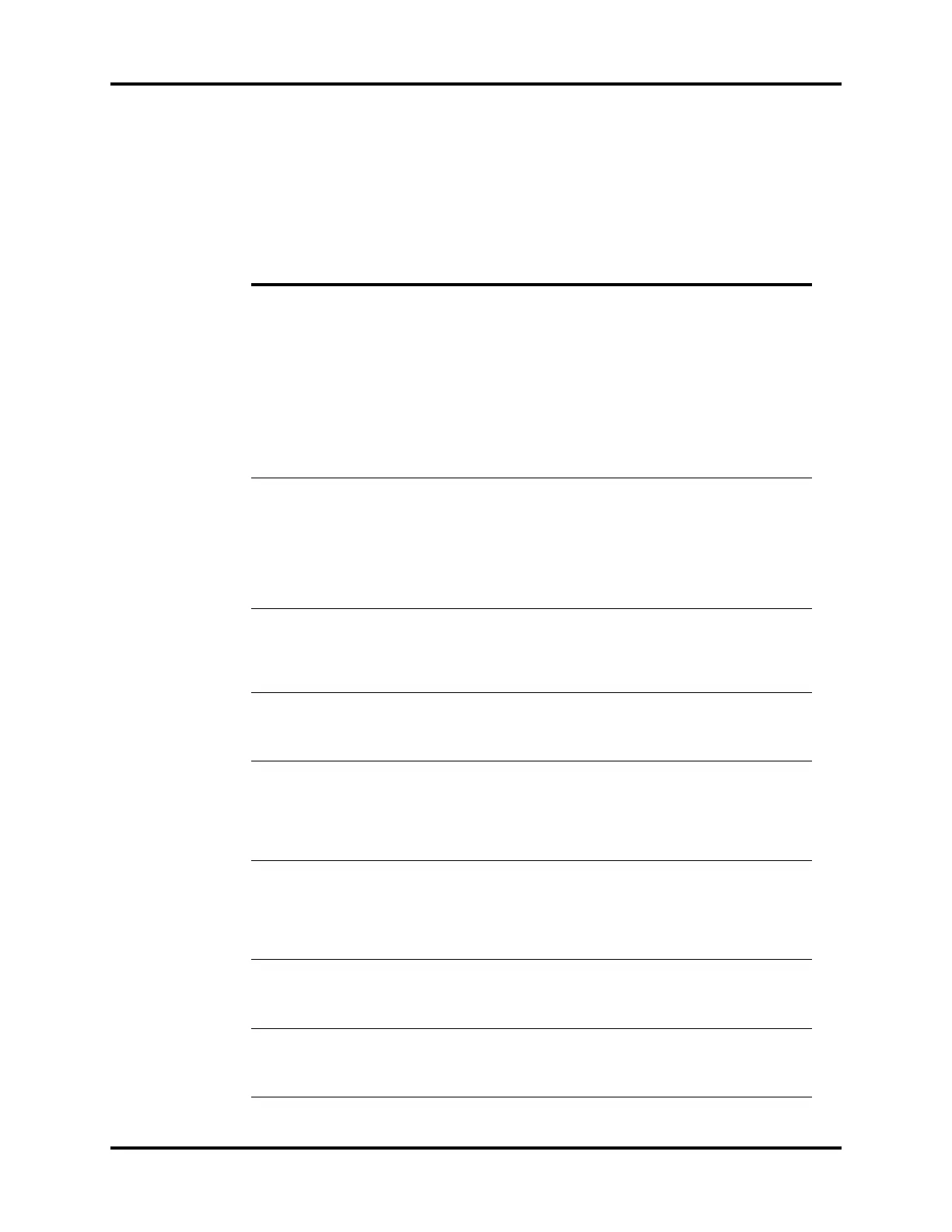

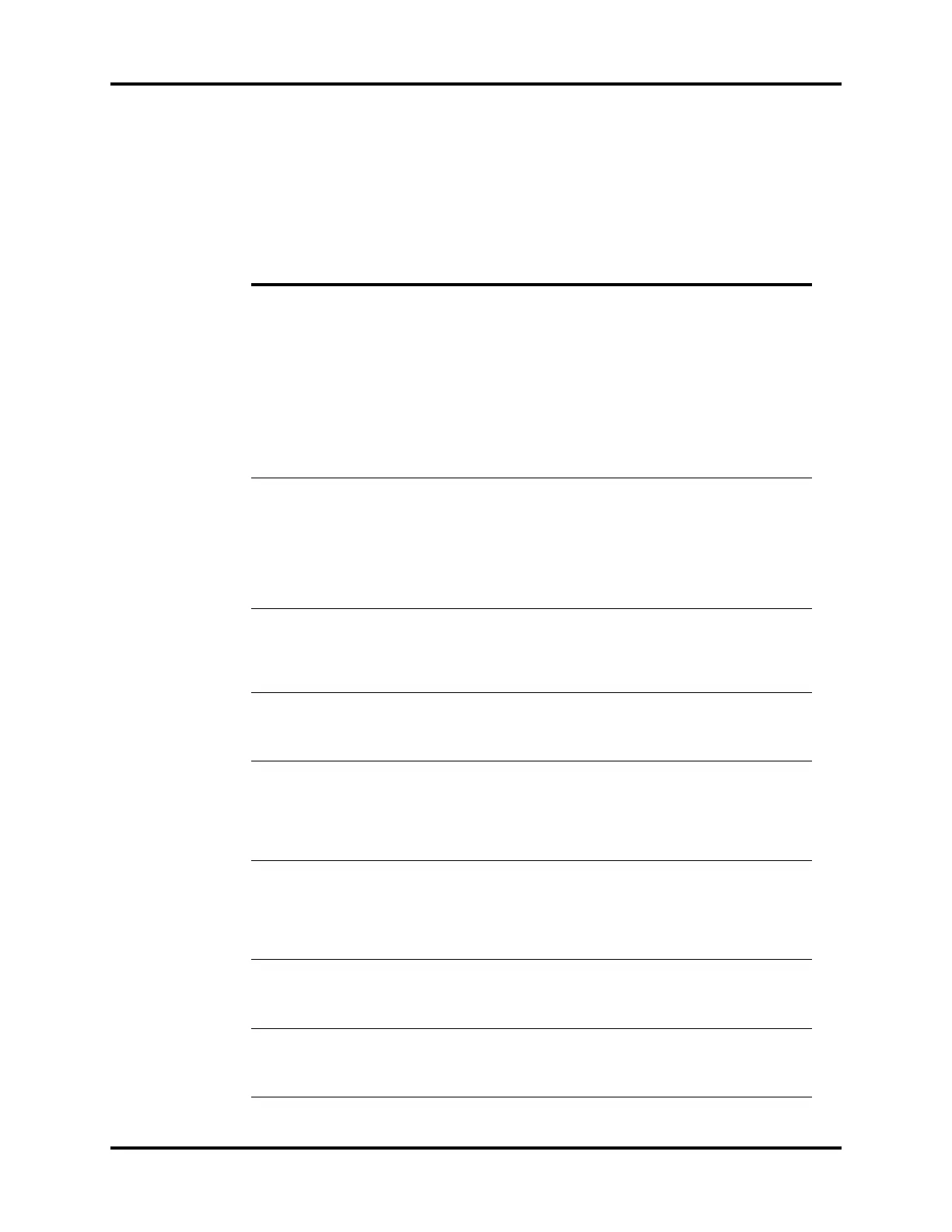

A5/A3™ Service Manual 046-001141-00 3 - 3

Periodic Maintenance Checklist before surgery

3.4 Checklist before surgery

Before the anesthesia machine at the client end is maintained, some routine tests are required to

check if the current status of the anesthesia machine is normal. The following table lists the routine

tests.

SN Test item Functional description Test interval

1

Check the

mechanical

ventilation

mode

1. Check if mechanical ventilation is provided normally

and if an alarm occurs.

2. Check if the preset values of pressure and TV are same

to the measured values.

3. Check if the pressure measured by the pressure sensor

is same to that indicated by the airway pressure gauge

and if the

TV measured by the flow sensor is same to that

indicated by the graduation on the bellows housing.

4. Roughly judge if the breathing system has a significant

leak by observing how much fresh gas is compensated

and observing if the folding bag collapses.

After each

service or at

the time of return

visit

2

Breathing

system leak

test in

mechanical

ventilation

mode

1. Check the pneumatic circuit in mechanical ventilation

mode for leaks, including bellows, drive gas circuit,

sodalime canister, patient tubes, flow sensors and their

connectors.

2. Check the control effectiveness of main control board

and auxiliary control board over PEEP safety valve.

3. Check the monitoring effectiveness of auxiliary control

module over airway pressure and PEEP path pressure.

After each

service or at

the time of return

visit

3

Breathing

system leak

test in manual

ventilation

mode

Check the pneumatic circuit in manual ventilation mode

for leaks, including APL valve, check valve, sodalime

canister, patient tubes, flow sensors and their

connectors.

After each

service or at

the time of return

visit

4

Check the

sensors’ zero

points

Check if the zero points of all the flow sensors and

pressure sensors inside the machine are within the

normal range so as to determine when to replace the

monitor board.

After each

service or at

the time of return

visit

5

Check the flow

sensor

accuracy

1. Check if the measurements made by the flow sensors

inside the machine are the same.

2. Check if the measurement made by any flow sensor

inside the machine is accurate.

3. Check the effectiveness of flow calibration (factory)

result.

After each

service or at

the time of return

visit

6

Check the

pressure sensor

accuracy

1. Check if the measurements made by the pressure

sensors inside the machine are the same.

2. Check if the measurement made by any pressure

sensor inside the machine is accurate.

3. Check the effectiveness of pressure calibration

(factory) result.

After each

service or at

the time of return

visit

7

Check the

electronic

flowmeter

accuracy

1. Check if the measurement made by the electronic

flowmeter is normal.

2. Check the effectiveness of electronic flowmeter

calibration result.

After each

service or at

the time of return

visit

8

Check the

AG module

a

ccuracy

1. Check if the measurement made by the AG module is

normal.

2. Check the effectiveness of AG module calibration

result.

After each

service or at

the time of return

visit

Loading...

Loading...